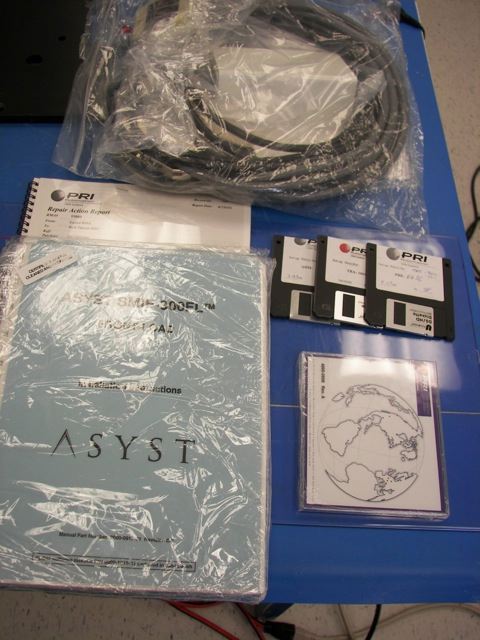

Used ASYST 300FL #46075 for sale

URL successfully copied!

Tap to zoom

ID: 46075

new Front end with Robot Controller track, load pods, pre aligner. All SW and HW, mates with KLA products AIT XUV, or AIT UV, or PUMA 9000 or ATI III, or AIT XP.

ASYST 300FL Wafer Handler is a specialty robotic arm designed for semiconductor fabrication processing. The equipment offers precise robotic movement to ensure accurate and consistent placement of wafers at any preprogrammed processing station. The wafer handler utilizes a coordinated series of motions, including linear and rotational, to accurately and reliably move wafers during processing. The handler offers high speed, repeatable motion and is able to accurately position a wafer in less than 200 milliseconds. The unit is equipped with an end-effector arm that can handle up to 300mm wafers and has an accuracy tolerance of +/- 25 microns. The handler has a modular architecture and can be customized to meet specific application requirements. Its modular design can also accommodate a range of options. It is capable of handling one to four wafers simultaneously and can be wired with an additional sensor for alignment. The entire system is controlled by a PLC and simple mechanical structure, including multiple sensors and limit switches, for superior wafer handling performance. 300FL Wafer Handler is designed for harsh environment operations and offers superior performance for semiconductor processing. It is able to operate under almost any temperature and humidity range. Additionally, its design ensures a high level of protection against dust, moisture, and other environmental contaminants, allowing for steady and reliable operation. The unit also features a built-in self-diagnostic machine for maintenance and repair services. Overall, ASYST 300FL Wafer Handler is a robust tool designed for precise and consistent wafer handling during semiconductor production. It is designed for accuracy, reliability and longevity, and offers a wide range of options and customizable components. With its advanced design, it is able to accurately position a wafer within milliseconds, allowing for a high performing, streamlined, and automated production process.

There are no reviews yet