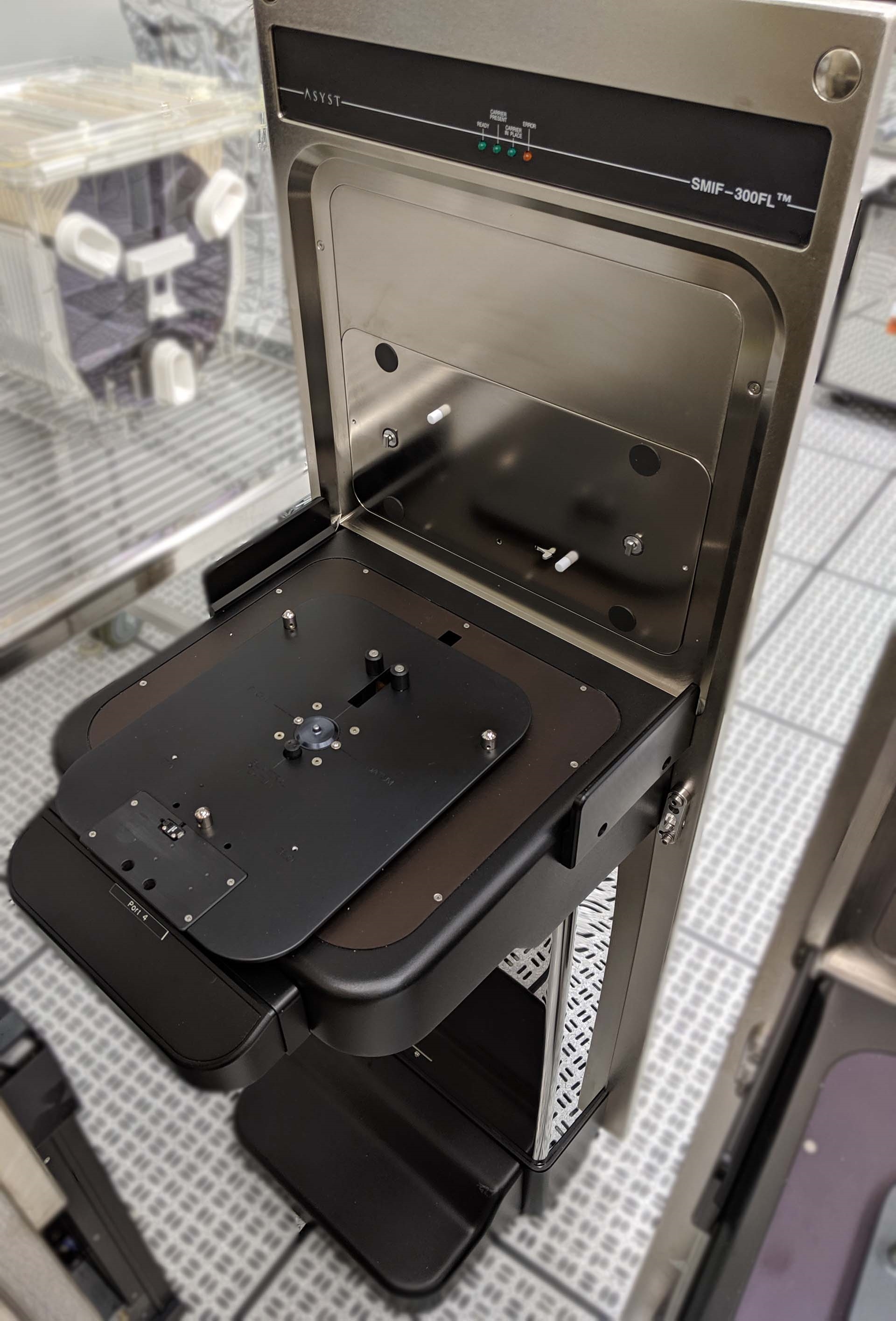

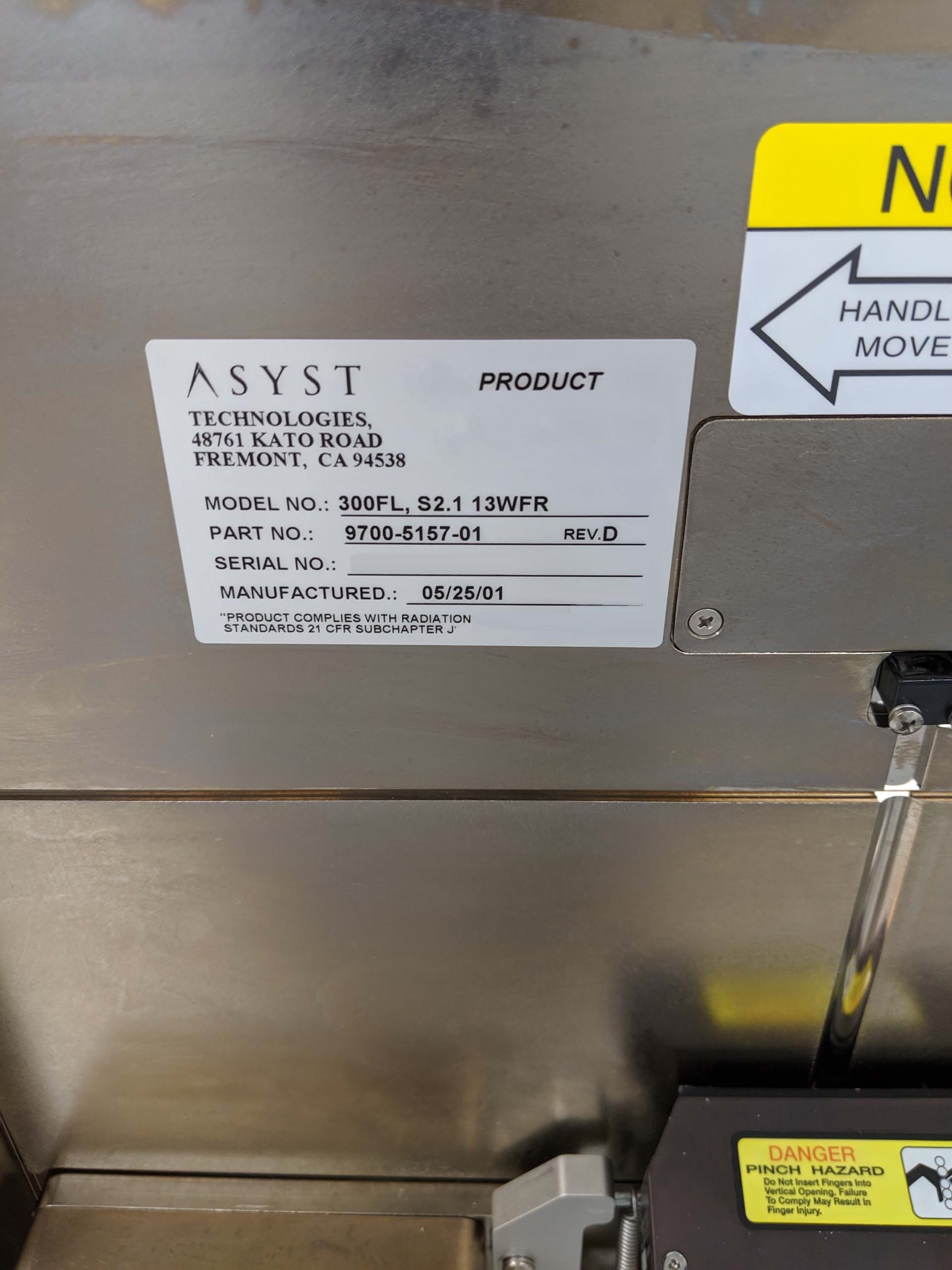

Used ASYST 300FL #9255538 for sale

URL successfully copied!

Tap to zoom

ASYST 300FL wafer handler is used in semi-conductor production and is designed to facilitate robotic wafer handling. This wafer handling equipment features reliable, quick and repeatable part placement for automated production lines. It is designed for quick and flexible manipulation of small parts and has a small footprint to save space. 300FL is capable of handling semiconductor wafers up to twelve inches in diameter with maximum accuracy. Its state-of-the-art stepper motor and advanced control system allow for precise orientation and placement of the wafer. This ensures consistently high yields over many production runs. The unit is designed for reliable, continuous duty operation. Its controls and software are designed for easy set up and operation, allowing operators to quickly change settings on the fly with minimal training. The stepper motor provides precise, repeatable motion and the internal memory stores process parameters and recipes. For maximum reliability and accuracy, ASYST 300FL is equipped with full-range and fail-safe sensors. These help to protect against accidental rescissions of commands and keep the machine running safely and smoothly. The self-calibrating tool balances and maintains the asset's eccentricity, ensuring dependable part placement. 300FL is built to handle extreme environmental conditions and lasts for many years with minimal maintenance. Its dustproof, waterproof construction helps to prevent short-circuits and other model malfunctions. The equipment is also designed with a long lasting, durable drive train with direct drive and special lubricants for longer life. ASYST 300FL is backed up by excellent customer support and a comprehensive warranty. This wafer handling system is designed to reduce downtime and increase yields in automated production environments. With its user friendly controls and reliable performance, it is one of the most trusted products in the industry.

There are no reviews yet