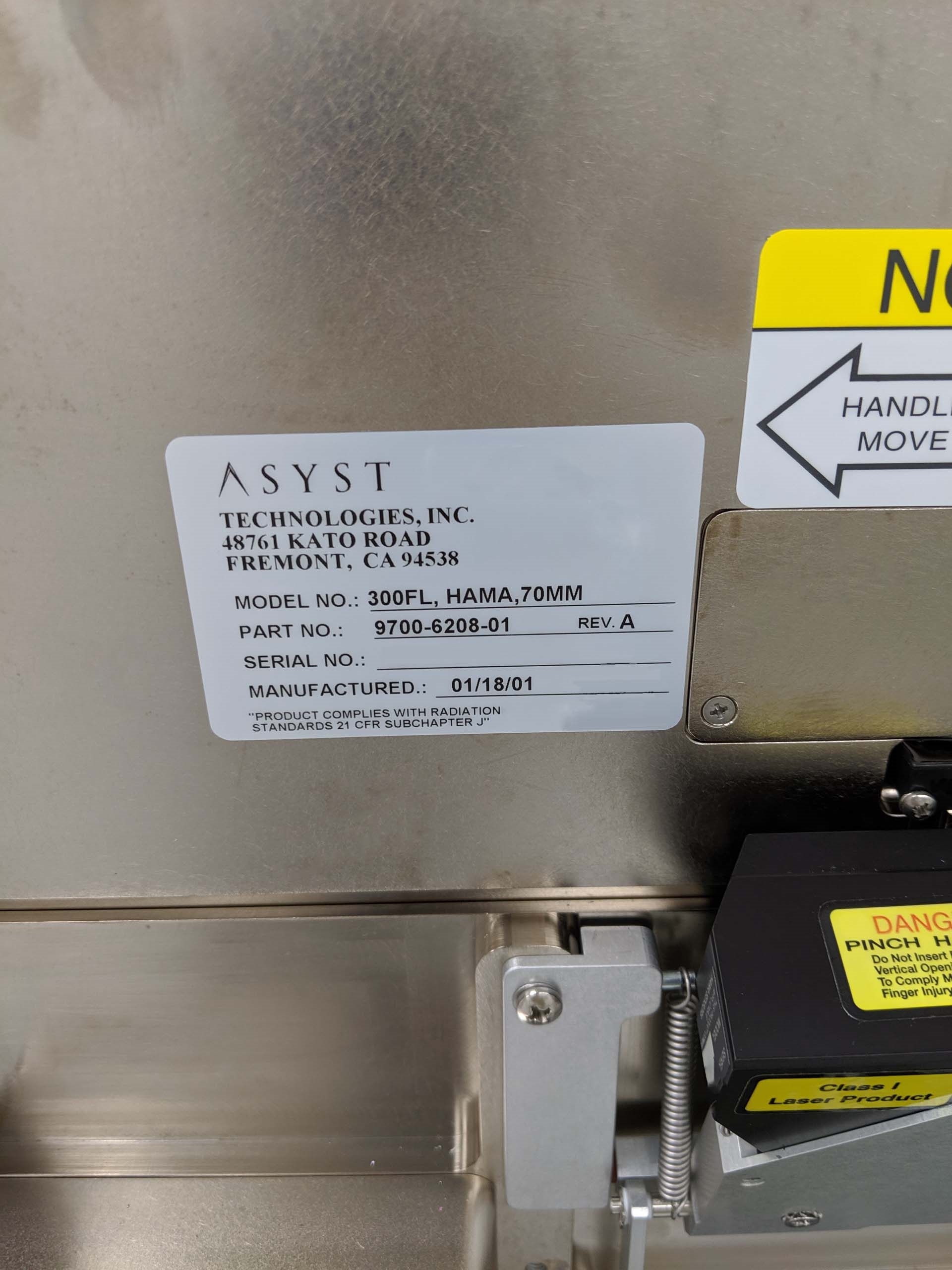

Used ASYST 300FL #9255540 for sale

URL successfully copied!

Tap to zoom

ASYST 300FL is an automated wafer handling equipment designed specifically for the fabrication of integrated circuits (IC) on semiconductor wafers. 300FL is a high-precision instrument that provides accurate and reliable wafer transfer and alignment operations. It uses a proprietary two-dimensional (2D) wafer transfer module that allows for quick initialization and flexible operation. ASYST 300FL employs a vision system that utilizes standardized algorithms for wafer precision alignment and placement. This unit is capable of achieving accuracy rates of up to 1.5µm, making it suitable for delicate fabrication processes. The vision machine also provides a comprehensive range of wafer placement, rotation, and pincushion correction features. Additionally, 300FL is equipped with a series of in-situ sensors that monitor the wafer throughput and further enhance the tool's performance. ASYST 300FL's flexibility is further extended through its reconfigurable design. It can be easily reconfigured to accommodate different wafer sizes and to process up to two wafers simultaneously. This allows for higher throughput and larger capacity. Furthermore, its robust design ensures a high degree of reliability and a long product lifetime. 300FL is capable of transferring wafers between carrier cassettes and processing machines, or modules. The wafer handling asset can transfer wafers into and out of cassettes in a matter of minutes. It also provides options for automated and manual loading and unloading of wafers. ASYST 300FL is designed to interface with many existing systems across the IC fabrication process. It comes with an intuitive user interface with easy access to the model parameters. Additionally, control and communication protocols are included to facilitate integration with other instruments in a production environment. 300FL is designed to perform at peak efficiency and minimize operator intervention. The equipment is capable of independently monitoring its operational parameters and reporting these parameters to the operator. This provides valuable insight into the quality and operation of the system, and helps to ensure a low level of down-time while maintaining high levels of throughput.

There are no reviews yet