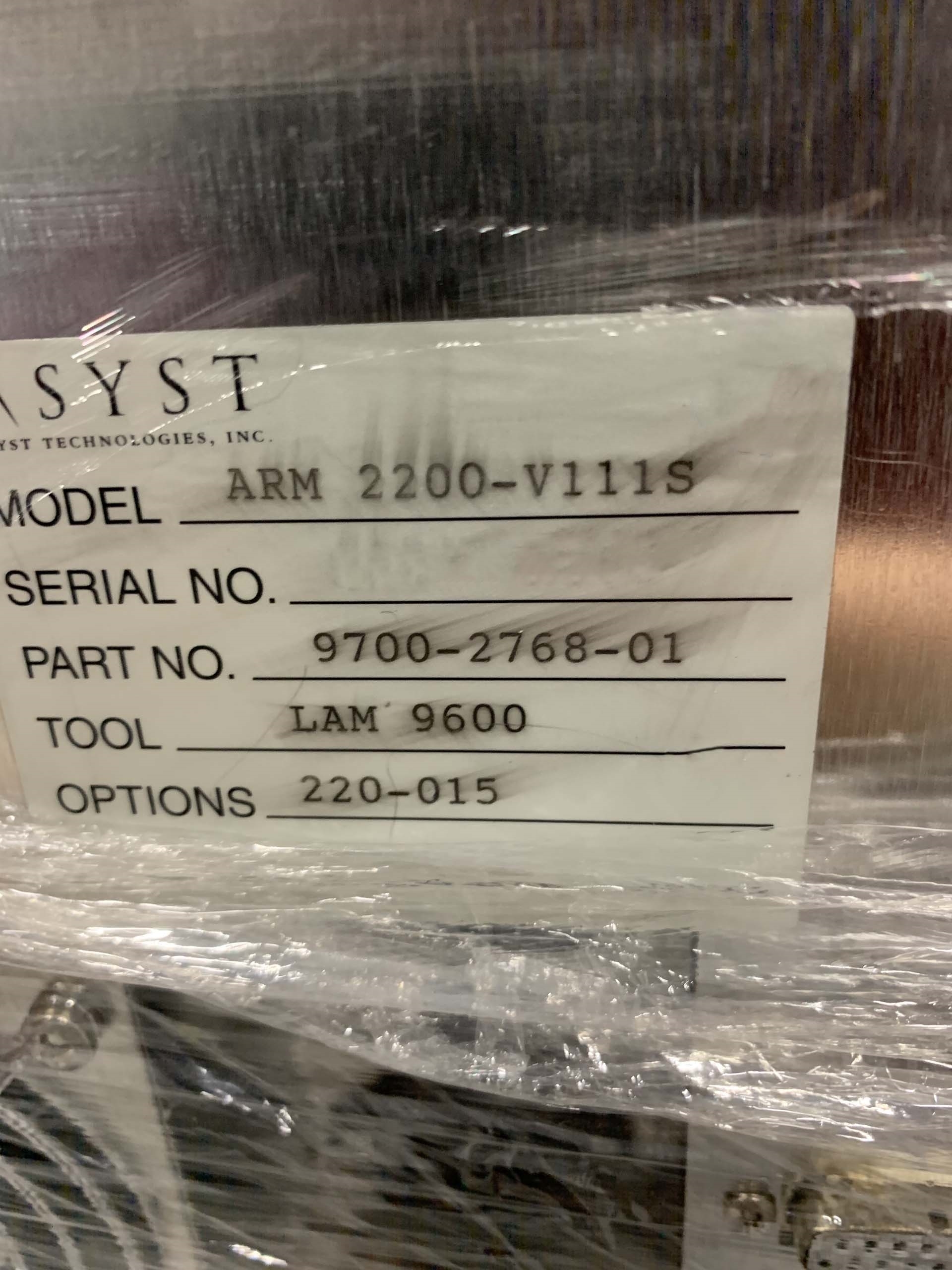

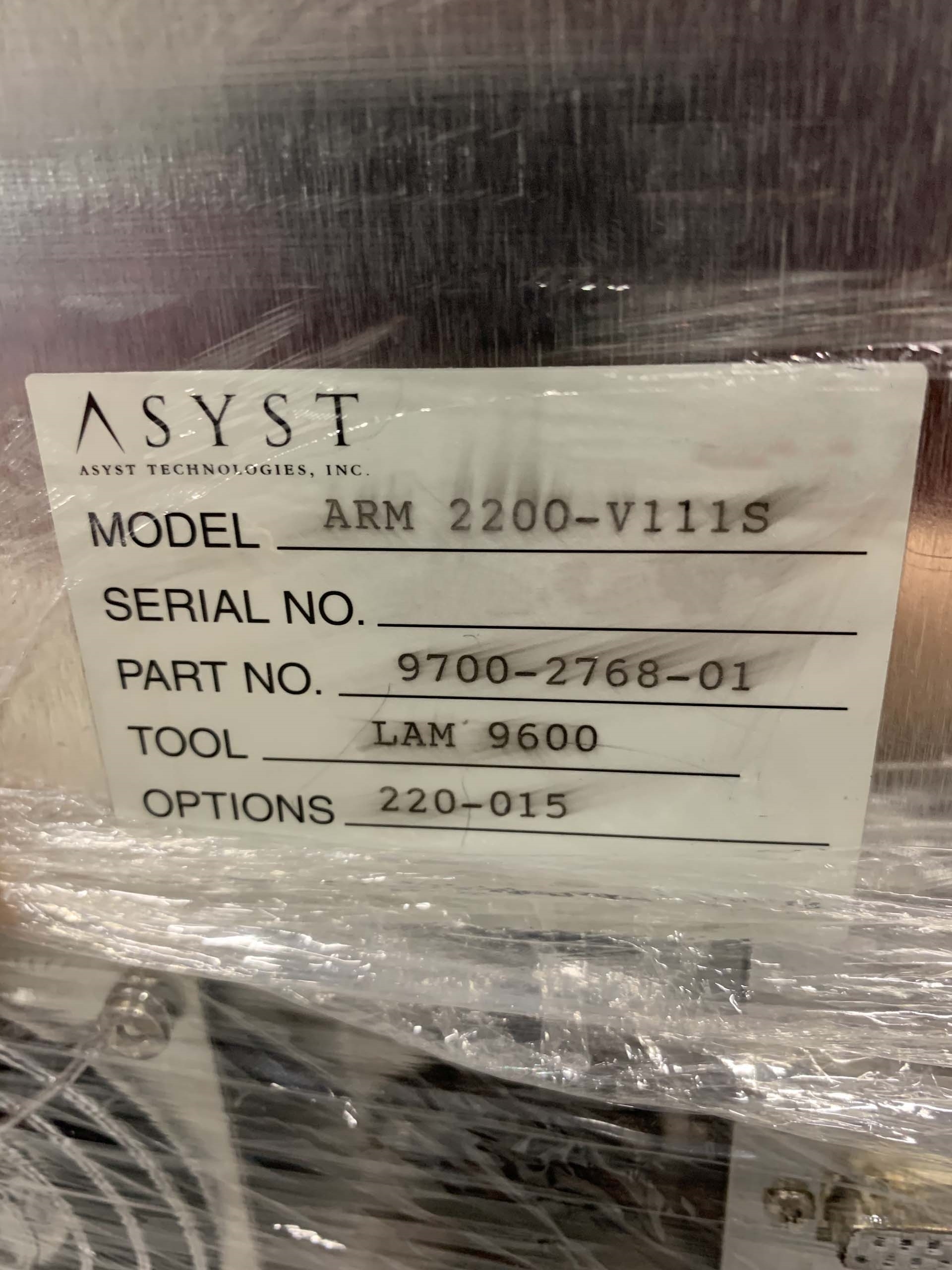

Used ASYST ARM 2200-V111S #9267066 for sale

URL successfully copied!

Tap to zoom

ASYST ARM 2200-V111S is a wafer handler designed for semiconductor wafer transport and manipulation. ASYST ARM 2200 V111S is composed of a circular arm with an integrated vacuum chuck, and a linear slide that can move the arm in the X, Y, and Z axes. The arm is controlled by a PLC controller and programmed via a programmable keypad, and it is also equipped with an integrated safety interlock equipment to prevent accidental operation. The arm is encased in a stainless steel body with a system of custom-designed pneumatic bellows around the mechanism. The bellows protect the mechanism from particles, dirt, and other debris, and they also reduce the noise levels associated with wafer transport. The arm is equipped with both a contactless breakaway mechanism and a brake band unit to ensure secure wafer transportation. The wafers are loaded onto the arm using the integrated vacuum chuck, which picks up the wafers from the load port and moves them along the arm's track. The arm has extreme flexibility and can move with accuracy in both the X and Y direction. Additionally, ARM 2200-V111S has built-in software for data management. The software monitors the wafer transport process in real-time, and it also stores wafer recipes to minimize setup times when loading wafers. The machine also features an autosensing feature which automatically selects the correct load-port size for the wafer. ARM 2200 V111S is a state-of-the-art wafer handler designed with maximum efficiency in mind. It is capable of handling a wide range of wafers sizes and materials, and it is both precise and reliable in its operation. Furthermore, the integrated safety features and data management capabilities make ASYST ARM 2200-V111S an ideal solution for high-volume wafer transport applications.

There are no reviews yet