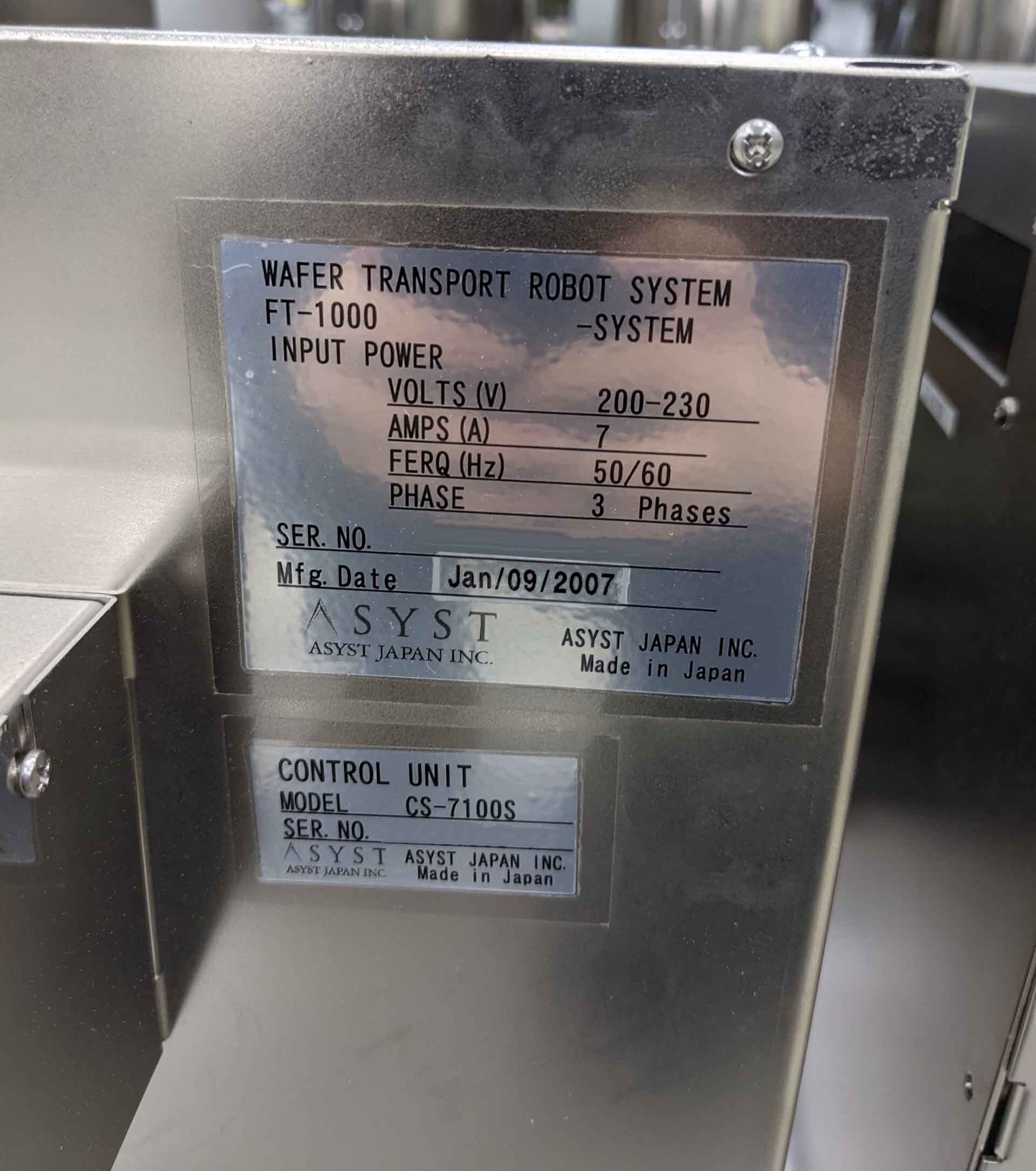

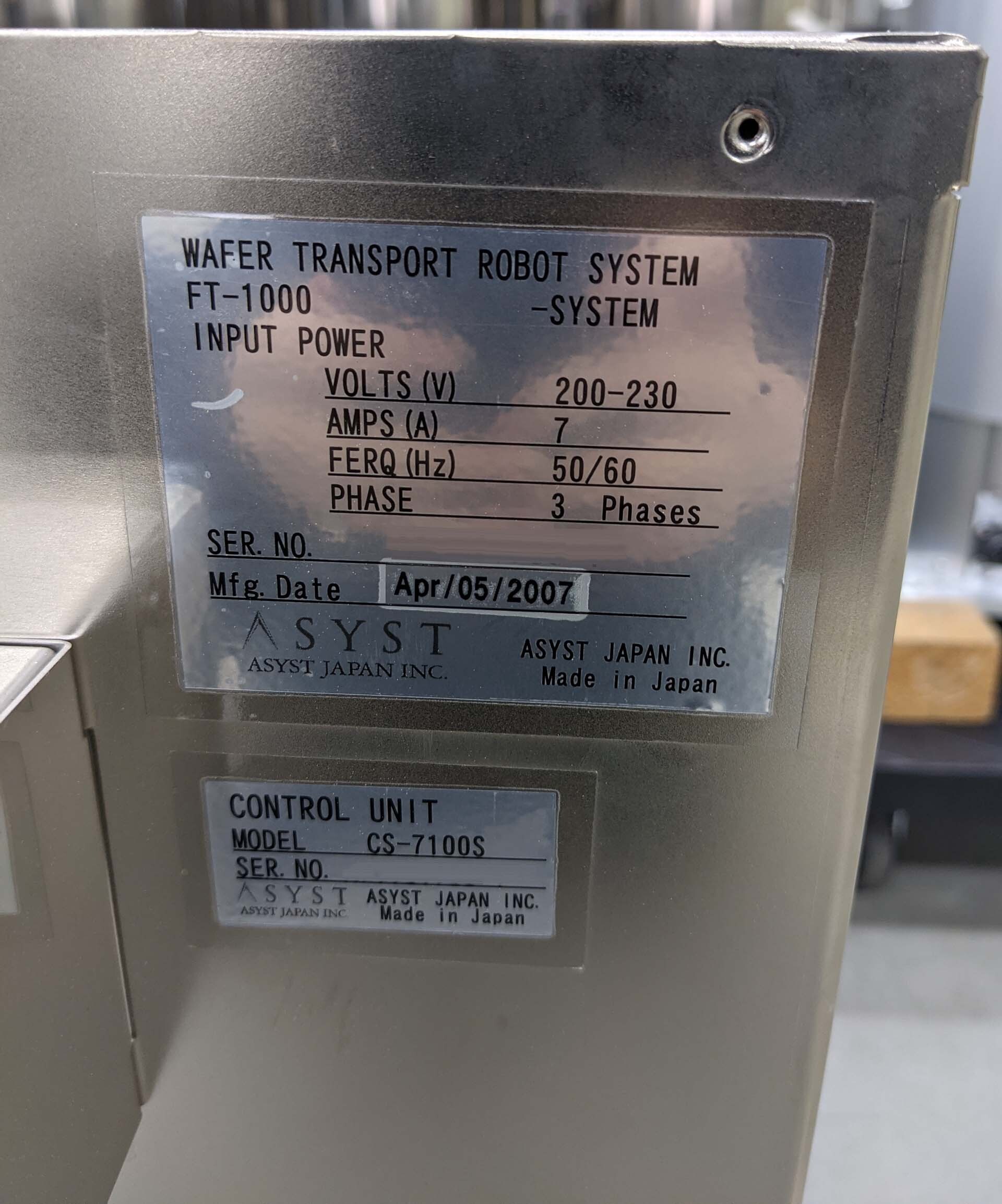

Used ASYST CS-7100S #9411618 for sale

URL successfully copied!

Tap to zoom

ASYST CS-7100S is a wafer handler designed to automate wafer handling in semiconductor test and assembly systems. This wafer handler combines a robotic wafer transfer equipment with advanced software control and automation capabilities to provide a high level of throughput and reliability for wafer processing tasks. CS-7100S is equipped with a specialized robotic transport system that can handle wafers from 150mm to 300mm in size. The transport unit utilizes a linear belt or magnetic gripper machine to secure and transport the wafer along its set path. This allows for a high throughput of wafers, up to 200 wafers per hour, with high positioning accuracy and repeatability. The wafer handler also features an intuitive user interface and advanced software control capabilities that make programming and monitoring of wafer handling functions easy. The software control tool incorporates wafer recognition and tracking capabilities so that each wafer is tracked through the handling process and processed according to the programmed instructions. This allows for highly advanced handling functions such as automated buffering and queuing, dynamic scheduling, and work list management. Furthermore, the asset is designed to be highly reliable and resistant to contamination. The wafer transfer model is built on cleanroom grade components and designed for easy cleaning and maintenance. It is also equipped with multiple sensors for touch and endstop detection, along with full ESD protection. ASYST CS-7100S is a powerful, robust and reliable wafer handling equipment that is highly suitable for automated semiconductor test and assembly setups. Its combination of advanced software control, intuitive user interface, and reliable transport system make it an ideal choice for wafer handling in a variety of industrial settings.

There are no reviews yet