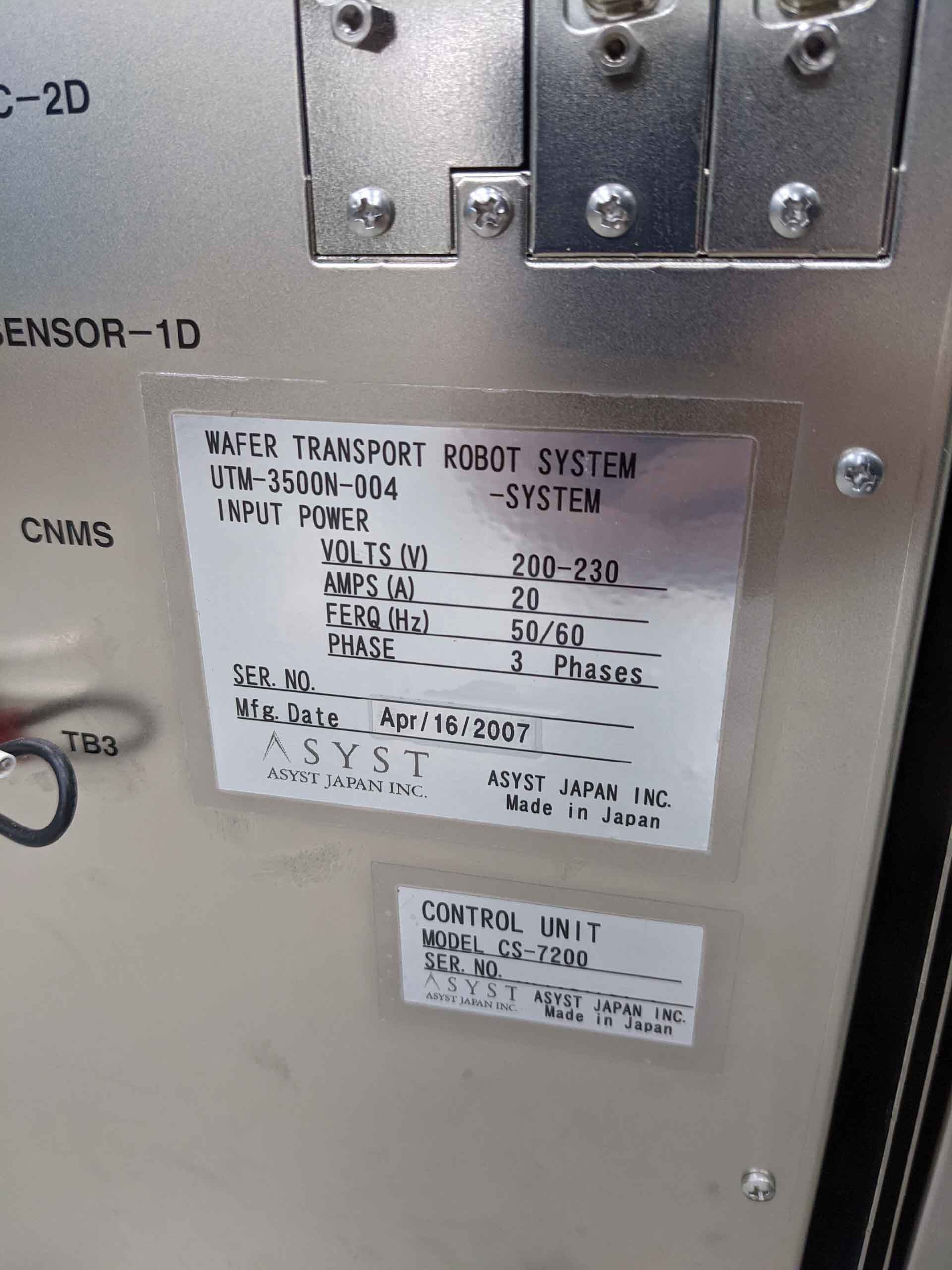

Used ASYST CS-7200 #9411616 for sale

URL successfully copied!

Tap to zoom

ASYST CS-7200 is a high-efficiency wafer handler designed for semiconductor fabrication. It is a fully integrated, uninterruptible and computerized execution equipment that can accurately transfer, align and exchange semiconductor wafers. With its advanced vision navigation technology, CS-7200 can perform process operations and increase throughput. The system is composed of a base cabinet and a mainframe unit with a range of mechanical and electronic components. Its robotic vision capability enables the unit to identify and precisely align wafers for loading and processing. The handler can be used in multiple settings from laboratory testing and production to scientific experiment and research. It also features an advanced multilevel alignment machine with 2.5-micron accuracy and a robotic positioning tool with 25-micron repeatability. ASYST CS-7200 provides an array of features that make it ideal for high-speed, exacting production of small or large batches of wafers. Its mechanical asset allows for accurate and repeatable operation, with a wide range of wafer sizes and thicknesses. The model is designed with a low-vibration integrated suspension. This ensures the highest yields, even at high speeds, while providing the highest quality engineering. CS-7200 is also equipped with powerful controllers, an intuitive user interface, and an extensive library of operator-friendly testing and calibration protocols. An external illumination equipment also comes standard with the wafer handler. The illumination system helps facilitate accuracy by providing a consistent light source for the alignment and retrieval of wafers. ASYST CS-7200 wafer handler is ideal for high-volume semiconductor processes. With its precision operation and robust tools and libraries, the unit provides increased throughput and ideal quality control. This makes it an ideal choice for any production lines that require a high degree of accuracy and speed. Furthermore, the machine is designed with a modular configuration that allows for upgrades and modifications to suit different production requirements.

There are no reviews yet