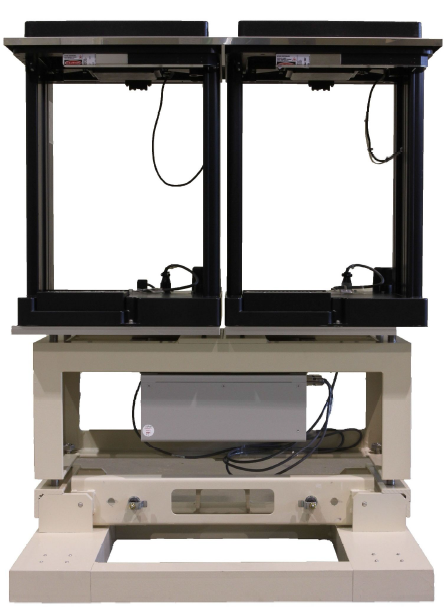

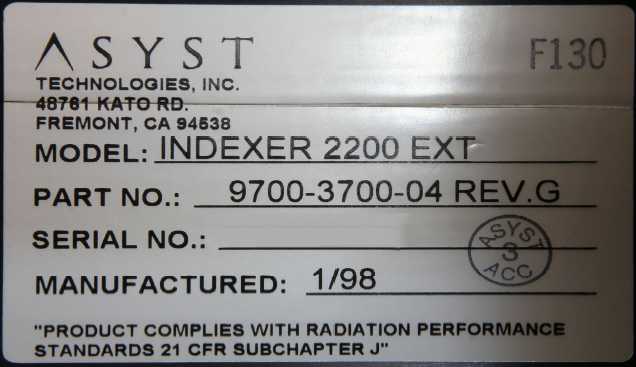

Used ASYST INX 2200 EXT #9103790 for sale

URL successfully copied!

Tap to zoom

ASYST INX 2200 EXT wafer handler is an automated, flexible and reliable wafer processing equipment designed for high throughput and efficient production of basic linear and random tasks. The system is designed to handle up to 25 wafers at once, improving wafer processing times and accuracy. The unit consists of a robot arm with a wafer loadarm, a horizontal load port, and a robotic arm machine controlled by a graphical user interface. The robot arm is controlled by an intuitive, user-friendly GUI which allows the operator to quickly and easily set processing parameters and command robot sequences. The robot arm is driven by a stepper motor and is capable of reaching speeds of up to 24 meters per minute (m/min). The robot arm is equipped with a load arm that is capable of carrying up to 25 wafers, enabling efficient and accurate wafer alignment and transfer. The load arm is designed to be easily adjusted and can be modified for special wafer fixtures. The tool also includes a horizontal load port which allows for the loading, unloading and transferring of the processed wafers. The load port is compatible with a variety of wafer cassettes and cassettes holders and is designed to efficiently transfer up to sixty wafers at a time. The load port is connected to the robot arm and is driven by a belt and pulley asset. The model also includes integrated process control, allowing users to monitor processing conditions and the quality of the processed wafers. An on-board data logger allows users to quickly view and analyze process data and set up automated processes. The equipment includes built-in safety features such as automated shut-off when non-operational conditions are detected and contact-less safety sensors. INX 2200 EXT wafer handler is a reliable and robust system that can perform high throughput and precise wafer processing tasks. The unit's user-friendly GUI, fast processing speeds and ability to carry up to 25 wafers make it an ideal choice for high-volume production environments. The machine is suitable for a wide range of applications, including semiconductor wafer manufacturing and photolithography.

There are no reviews yet