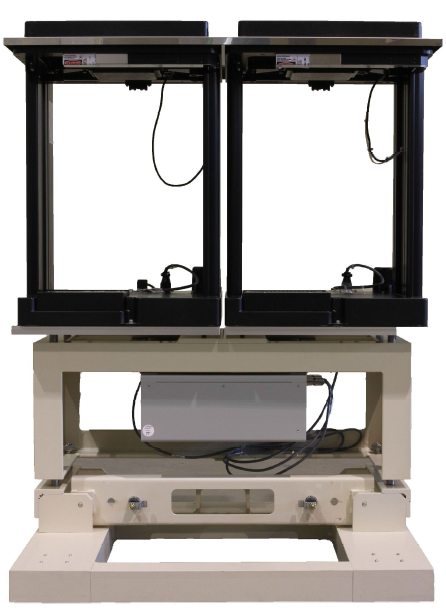

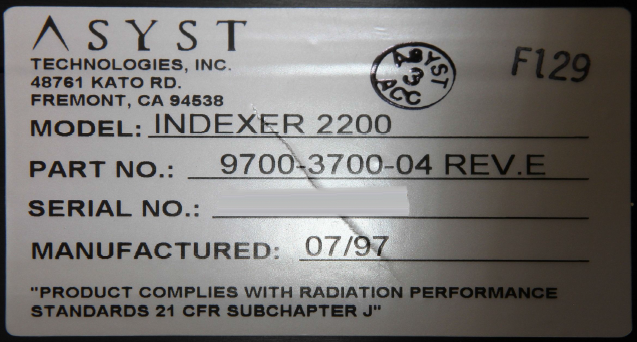

Used ASYST INX 2200 #9103792 for sale

URL successfully copied!

Tap to zoom

ASYST INX 2200 is a wafer handler designed to transfer wafers into and out of vacuum chambers with precision. This versatile equipment handles a variety of wafer sizes up to 8 inches in diameter and can accommodate both front and back loading. ASYST INX2200 incorporates advanced features including Autochuck, a powerful and precise one-touch loading system, and AutoRotate, a two-axis arm for enhanced wafer positioning and orientation. INX-2200 begins operation with the Autochuck loading unit. This machine precisely aligns and places a wafer onto the handler's port, ensuring the highest level of wafer accuracy and repeatability. The Autochuck tool is equipped with sensors which analyze the wafer's size, orientation, and composition to ensure a precise fit. This prevents damage to delicate wafers while improving performance and throughput. INX 2200 can also quickly position and adjust the orientation of each wafer during loading and unloading. The AutoRotate asset uses a two-axis arm to move the wafer into position before entering or exiting the vacuum chamber. The arm's travel range, wafer positioning accuracy, and repeatability are all adjustable to accommodate the exacting demands of a variety of applications. INX2200 is designed for reliable, long-term operation in a variety of environments. Its frame is designed for maximum stiffness and rigidity, while lightweight components reduce moving masses for faster cycle times and improved performance. Its electronically-controlled stepper motor drive model offers precise motion control and reliable operation. ASYST INX-2200 is protected from environmental contamination via its hidden Nylon-6/6 material and internal stainless steel frame, meeting or exceeding all semiconductor industry standards. ASYST INX 2200 offers state-of-the-art precision, durability and performance while handling a variety of wafer sizes. This equipment is engineered to improve throughput, reduce costs, and ensure greater accuracy and repeatability during wafer transport and positioning.It is the perfect choice for an array of applications ranging from semiconductor manufacturing to advanced materials research.

There are no reviews yet