Used ASYST IsoPort #9249554 for sale

URL successfully copied!

Tap to zoom

ID: 9249554

Wafer Size: 12"

Vintage: 2007

Load port, 12", parts system

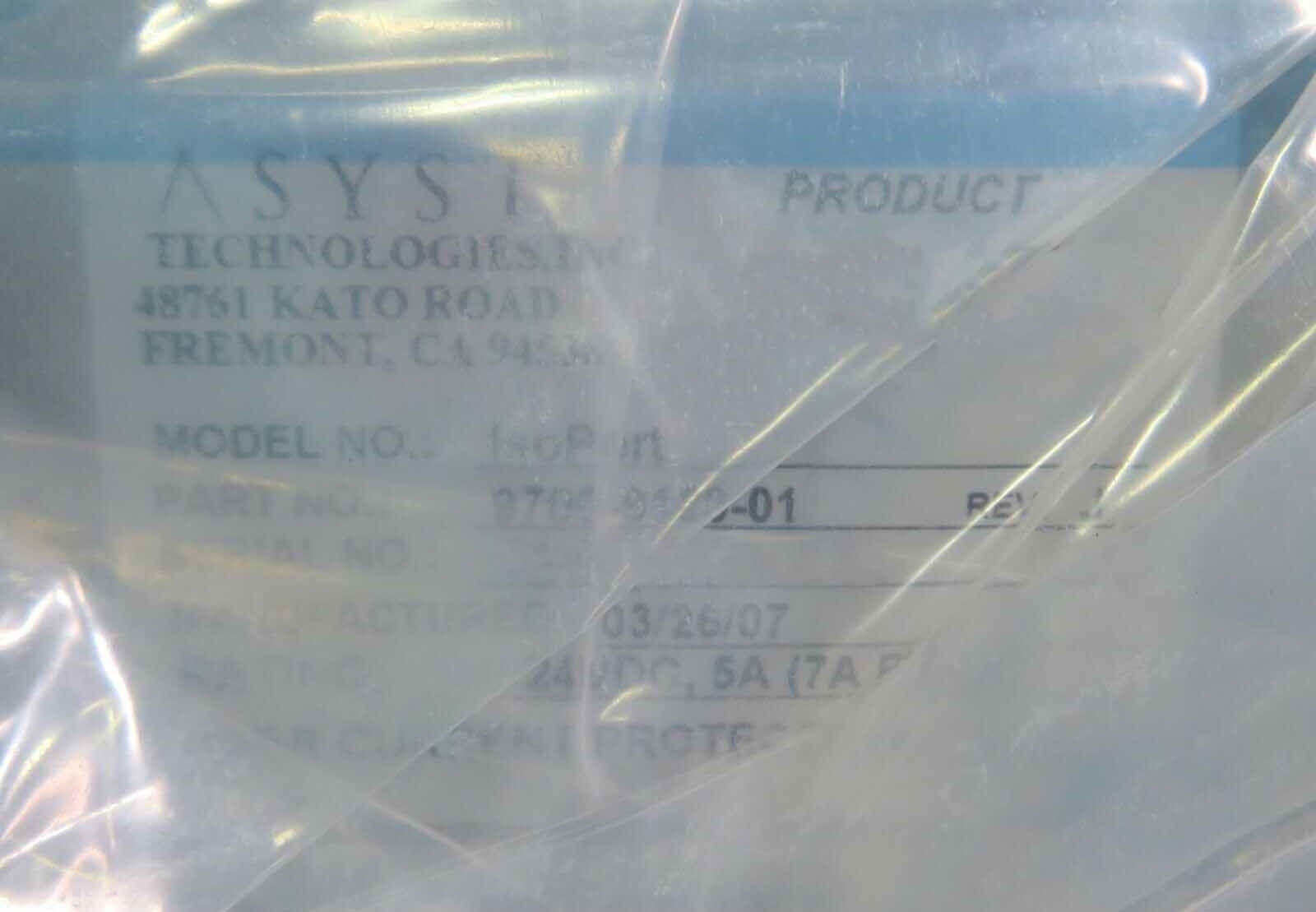

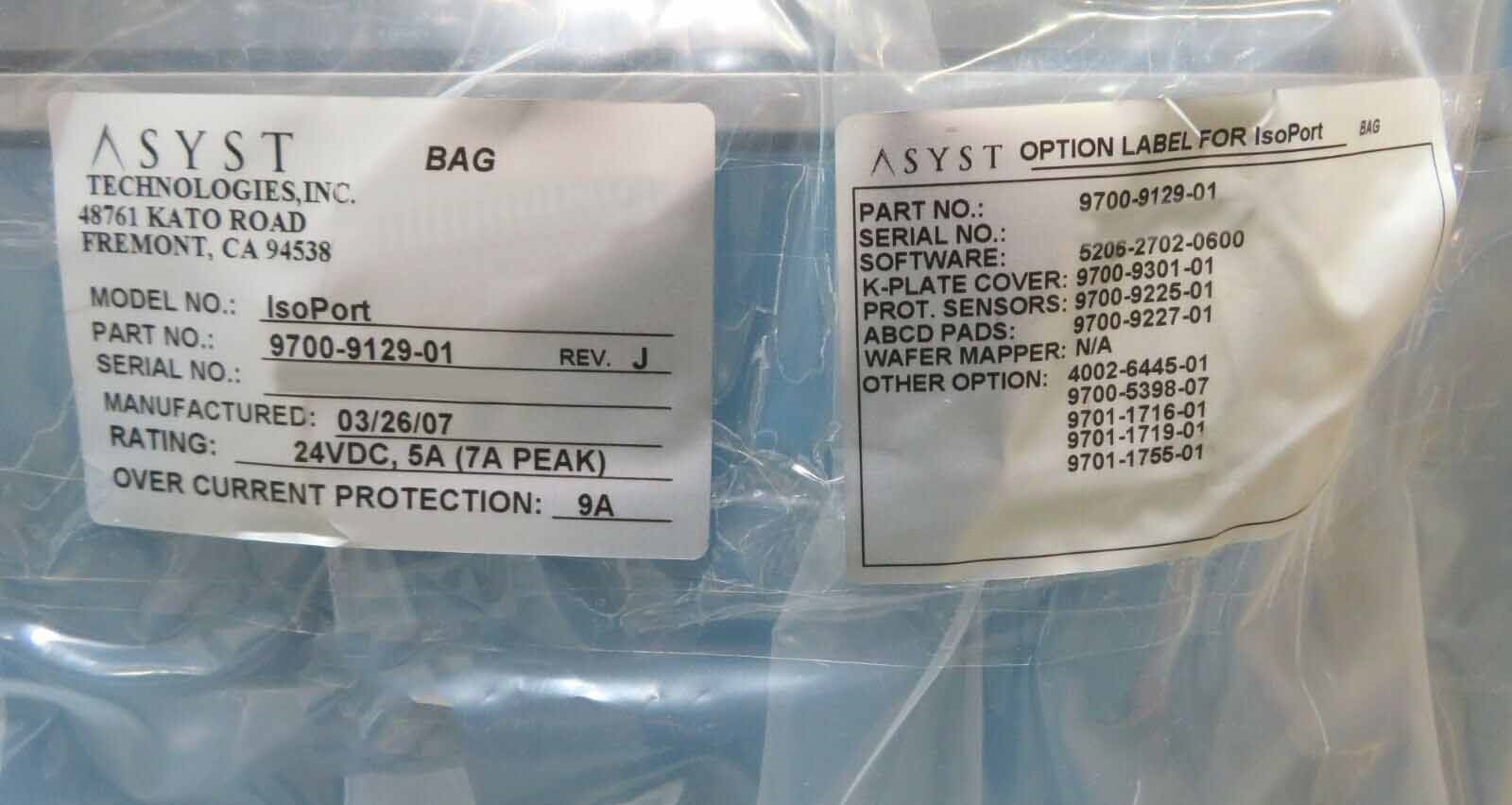

P/N: 9700-9129-01 Rev.J

Wafer loader, 12"

2007 vintage.

ASYST IsoPort is an integrated wafer handler designed for the automation of semiconductor processing tools. This machine is designed for the transportation of bare and processed semiconductor wafers in an cleanroom environment. It is capable of transferring wafers from its load ports directly to a variety of operating tools, such as single-wafer process chambers. Using a combination of up to eight robotic arms, high quality, air-mystation and ionization systems, IsoPort can move wafers from station to station quickly and securely. Additionally, the machine is equipped with an auto-calibration system, allowing it to quickly adjust its wafer gripping force, if necessary. ASYST IsoPort is also equipped with an ISO Class 4 cleanroom rating, making it ideal for ultra-clean and contamination-controlled environments. It is capable of transferring up to twenty-five (25) wafers in one cycle, with a maximum turnover rate of one hundred fifty (150) wafers per hour. Furthermore, it features a standard SiC (Silicon Carbide) coating and is equip with a propriety multi-point wafer detection system, which ensures accurate wafer identification prior to each processing cycle. Additionally, IsoPort features a suite of gas sensors, allowing operators to monitor and control process gases more accurately and efficiently. It also has a particle monitor, allowing operators to easily detect particles, debris and other contamination in the cleanroom atmosphere. Furthermore, a cassette-to-cassette capability is available, allowing the machine to be integrated into existing automated production lines. Finally, ASYST IsoPort is designed to reduce downtime, costs and environmental impact, by utilizing advanced motion control technology and advanced automation software. Its user interface includes an intuitive graphical user interface (GUI), which provides the necessary information to setup and operate the machine quickly and accurately. It also features safety sensors and special handling behaviors, to minimize the risk of damage to the wafers during transportation.

There are no reviews yet