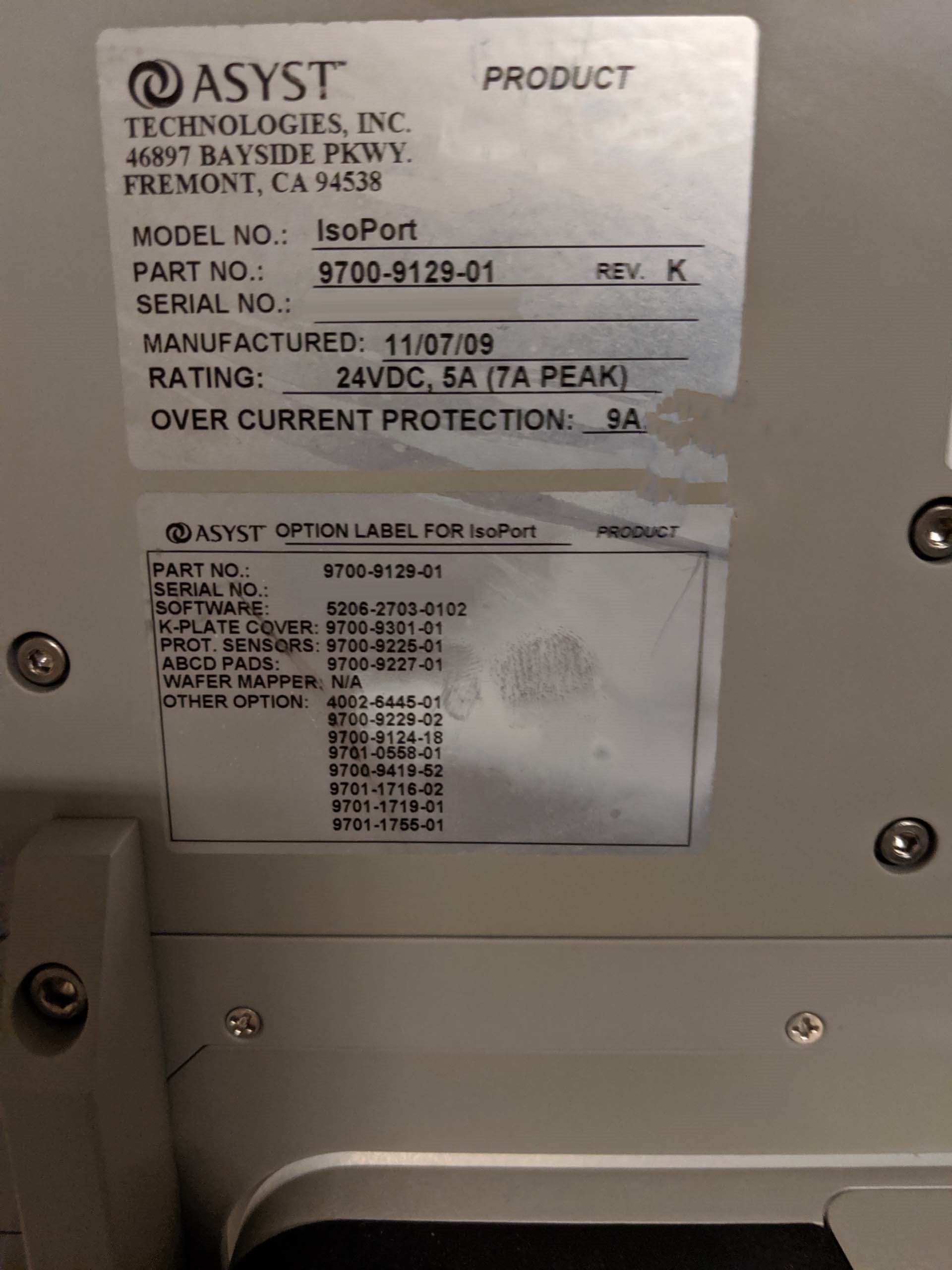

Used ASYST IsoPort #9255530 for sale

URL successfully copied!

Tap to zoom

ASYST IsoPort is a high-precision, low-particle wafer handler used in semiconductor manufacturing processes. It is designed to provide reliable, accurate, and repeatable operation in harsh and demanding process environments. The main components of an IsoPort wafer handler include a multi-station robotic arm, a wafer transfer equipment, and a wafer storage system. The robotic arm of ASYST IsoPort is equipped with custom end effectors that are able to securely handle and accurately place wafers in selected industrial and cryogenic environments. The arm is driven by electric motors and uses a patented low-vibration servo drive to minimize vibration, outgassing and particle generation. The wafer transfer unit uses linear motor modules to accurately place wafers at designated points in the process cycle. The wafer storage machine consists of a carousel-type inventory managed by a computer that provides the operator with efficient and easy access to wafers. The main advantages of IsoPort wafer handler are its repeatability, accuracy and its compact design. The robotic unit provides accurate and repeatable positioning of the end effectors, and its low vibration servo drive minimizes contamination. The wafer transfer tool is precise and repeatable, able to transport and place wafers accurately even at high speeds. Finally, its compact design allows it to fit easily into tight spaces in industrial and cryogenic environments. ASYST IsoPort wafer handler is designed to provide efficient operation and durability. It is equipped with redundant interlocks and anti-collision sensors that protect it and its component parts from damage and contamination. Finally, its stainless steel and plastic design - along with its sealed, fused and shielded environment - reduces outgassing and contamination and helps protect the component parts, even under the most demanding applications.

There are no reviews yet