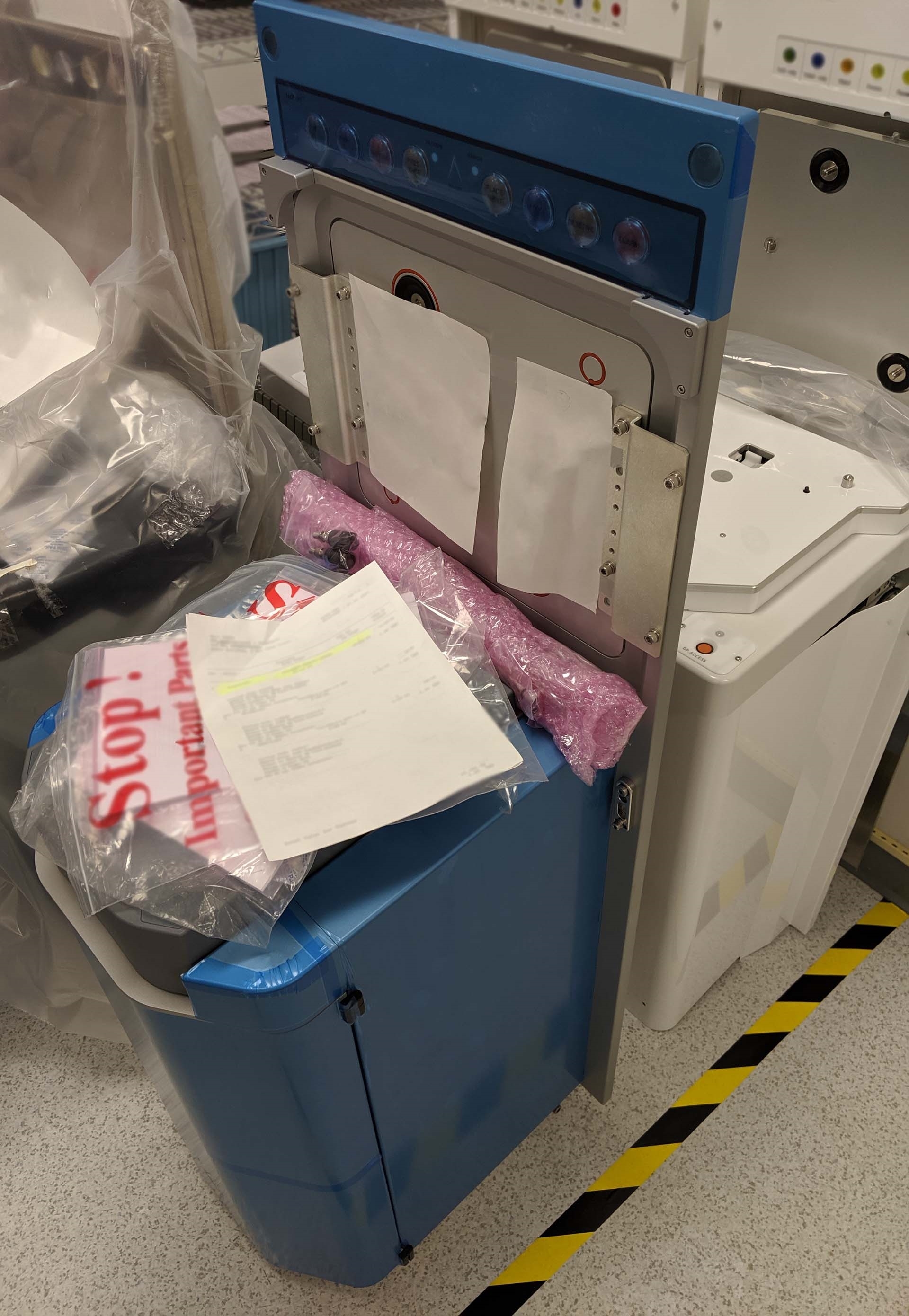

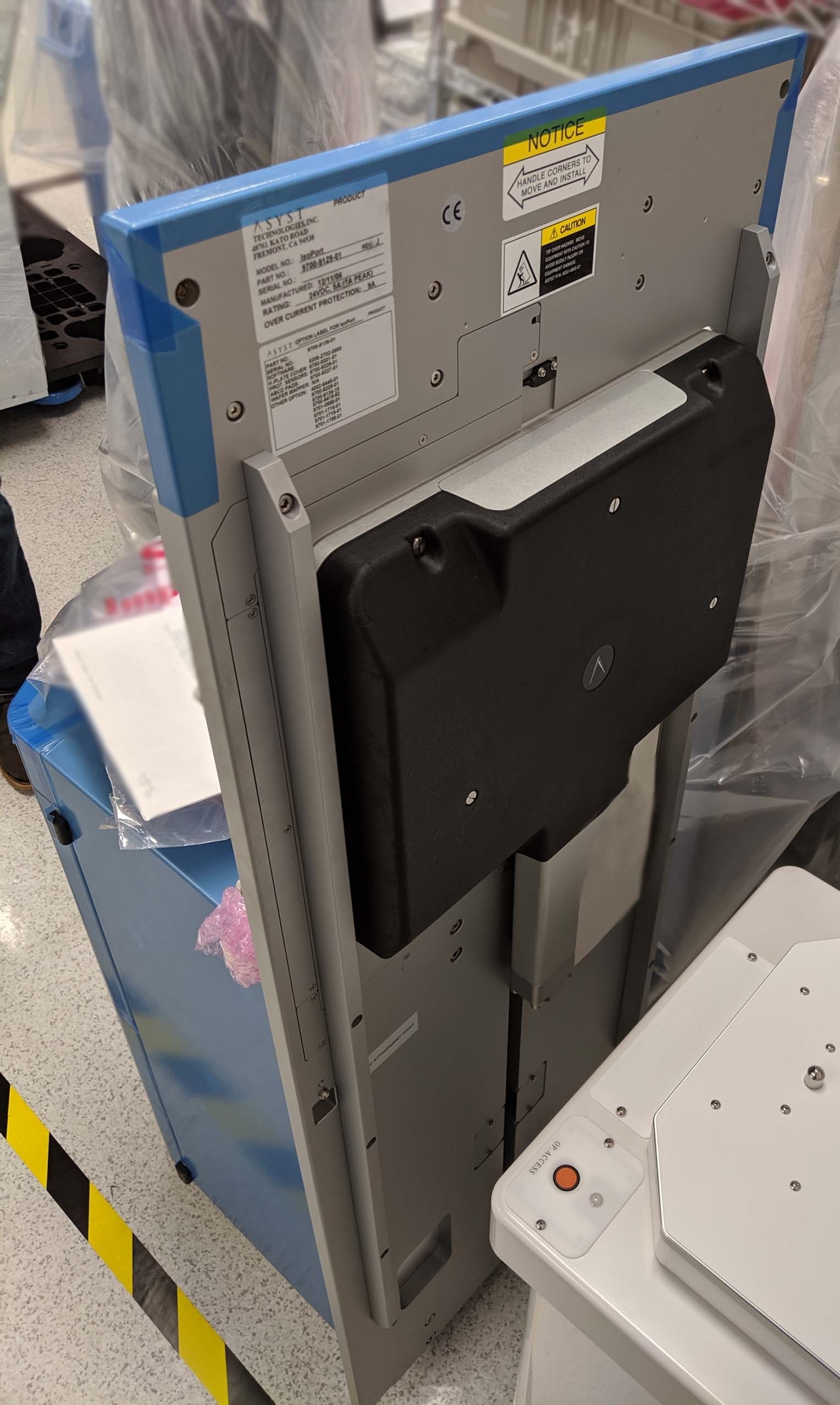

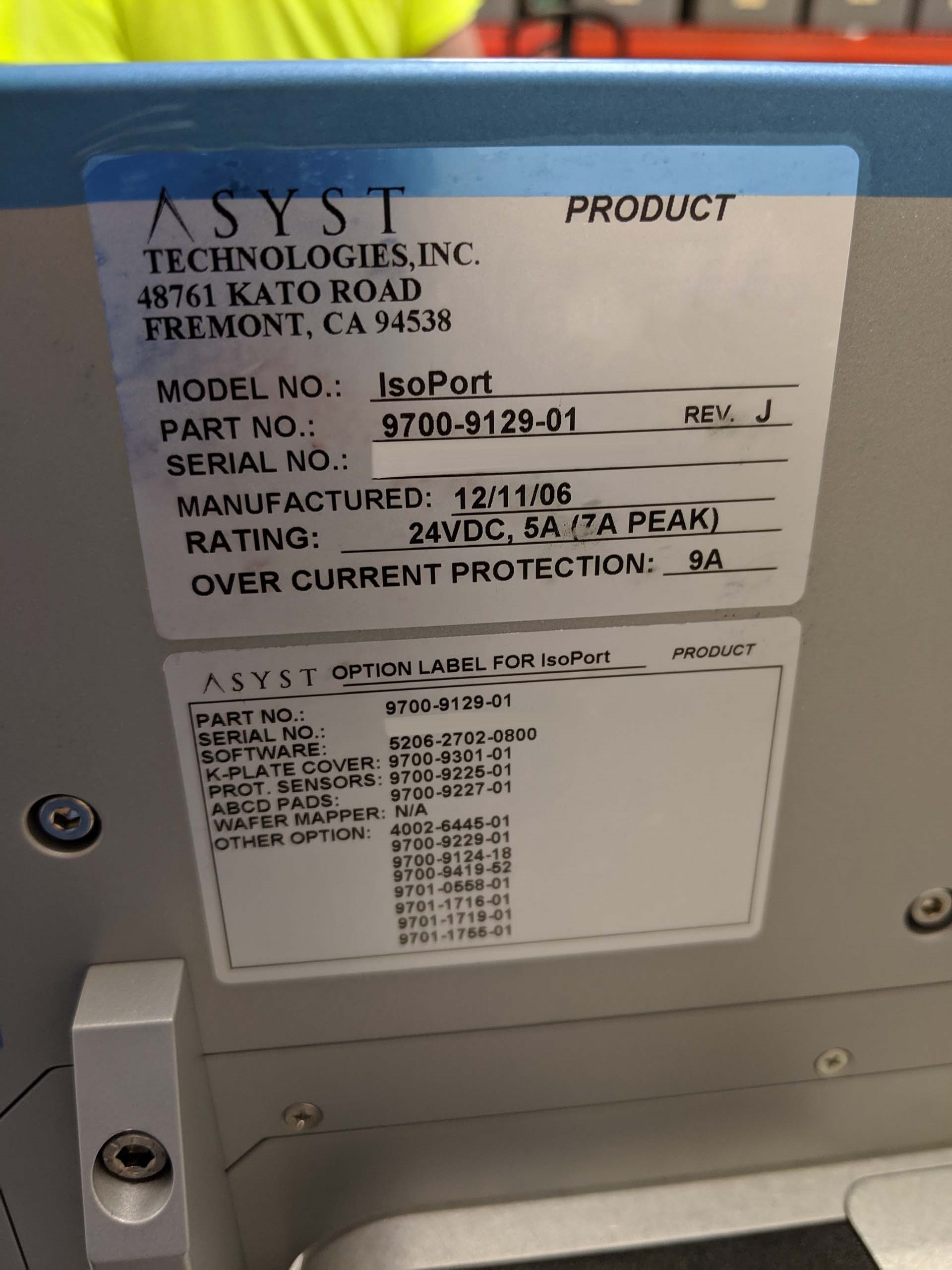

Used ASYST IsoPort #9255534 for sale

URL successfully copied!

Tap to zoom

ASYST IsoPort is a wafer handler designed specifically for wafer-level packaging, die-attach and singulation. This equipment offers advanced automation through its high-speed, precise, and reliable handling capabilities. The system includes an innovative robotic arm, vacuum spindle and tray handlers, which integrate seamlessly with a software-based control unit. The robot arm is programmable and provides precise motion control, while the vacuum spindle offers quick and precise transfer of wafers and die in a contamination-free environment. The machine provides a totally enclosed environment with airtight protection, which prevents potential contamination from entering. The self-contained enclosure and exhaust tool also helps to prevent any potential mechanical failure during the process. The robotic arm is capable of accurately aligning and positioning wafers and die for precise manipulation, which eliminates the need for manual loading and unloading. The built-in vision asset can detect wafer/die misalignments, as well as any possible defects. As a result, precision and accuracy are guaranteed in each operation. The model also includes sophisticated monitoring and control functions, including process monitor and control functions, digital input/output (GPIO) monitoring, error status and process report details, and audit trail logs, among others. This allows users to keep track of the various components and process parameters while they are running. The equipment also features a powerful, scalable software architecture. This offers an intuitive user interface, product design, as well as machine parameters automatic control. Furthermore, the system provides real-time feedback that helps users quickly adjust operations and make corrections if needed. IsoPort is fully compliant with international safety standards. It has been rigorously tested through multiple stages of development and testing to ensure unit robustness and reliability. The machine is capable of handling up to 200 wafers per hour, which makes it well-suited for high-volume production requirements. As a result, the tool is ideally suited for automation, semiconductor, and wafer level packaging tasks.

There are no reviews yet