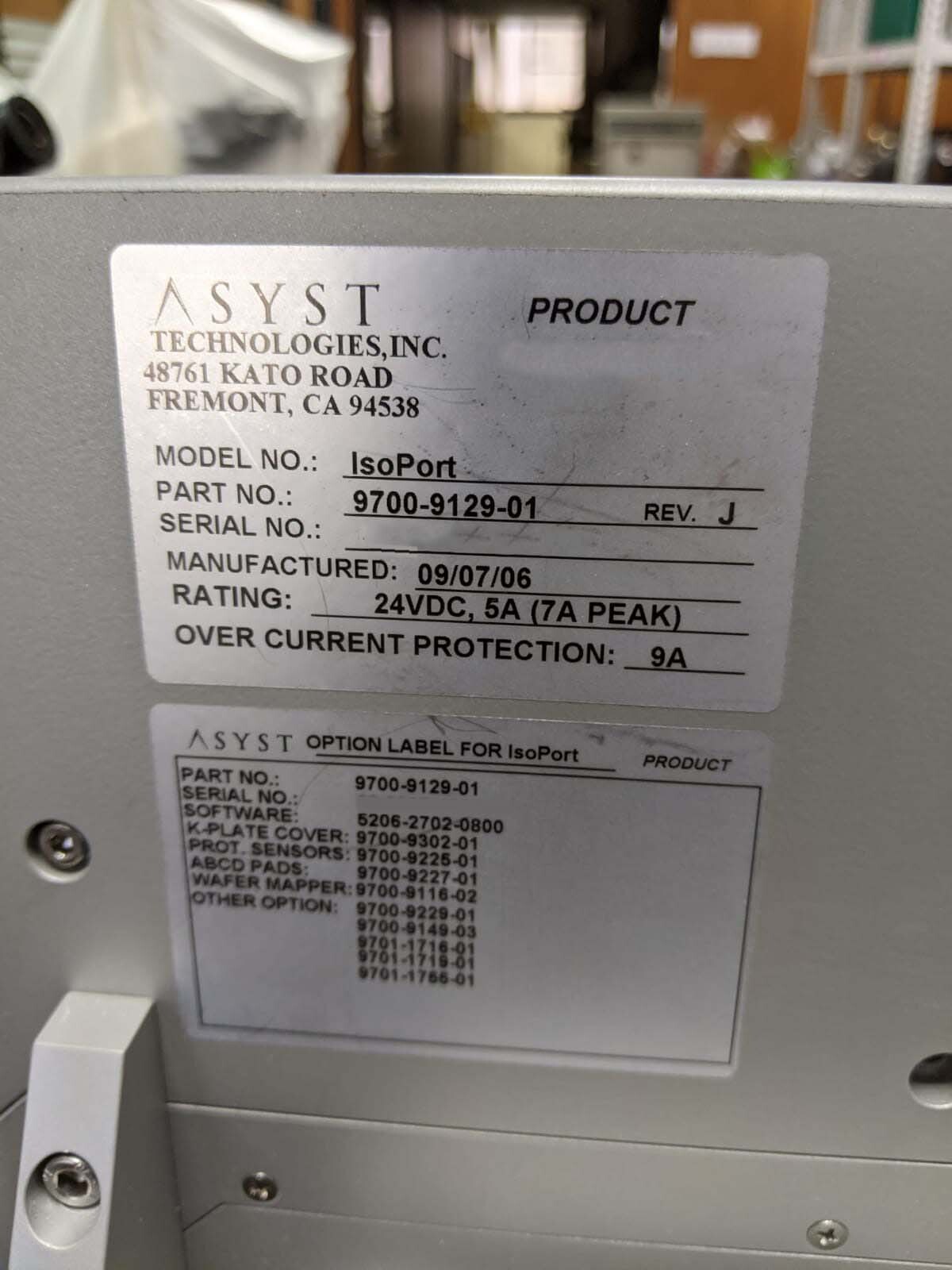

Used ASYST IsoPort #9375302 for sale

URL successfully copied!

Tap to zoom

ASYST IsoPort wafer handler is a versatile, efficient solution for transferring, sorting, storing and inspecting semiconductor wafers. It utilizes an advanced robotic arm for precise, secure handling of all semiconductor materials, including photomasks and substrates. Its modular design enables easy upgradeability to keep up with changing semiconductor production needs. IsoPort uses robotics technology and an ergonomic design to maximize wafer accuracy and throughput. The automated robotic arm is equipped with custom sensors, which provide real-time feedback and precise positioning of the selected wafer. This allows ASYST IsoPort to deliver precise, fast, and repeatable wafer movement. The robotics technology not only ensures accuracy and throughput but provides a high degree of safety during operation. IsoPort is designed to meet the demands of semiconductor industry standards. Its airtight enclosure, with cleanroom compatible materials, prevents airborne particles from entering and contaminating the wafers, ensuring a high quality product. The custom sensors also provide real-time feedback for precise positioning, monitoring, and diagnostics. The system also can be connected to a computer interface for remote diagnostics, troubleshooting, and analysis. ASYST IsoPort offers a wide range of flexible capabilities to meet customer needs. It is designed to accommodate a variety of wafer sizes, from 4 inch to 12 inch, making it well suited for both large-scale and small-scale semiconductor production runs. It also features a variety of configurable options, such as a bar code reader, fixtures, and different robotic arms. Additionally, the system can be adapted for use with various types of kitting, allowing it to as well as handle non-standard parts. For those looking for an efficient and cost effective solution for semiconductor production, IsoPort is the ideal choice. It delivers precise and reliable wafer handling, with a highly flexible setup, designed to meet diverse customer needs. Its robust airtight enclosure, high-speed robotic capabilities, and comprehensive diagnostics make it ideal for semiconductor production and test applications.

There are no reviews yet