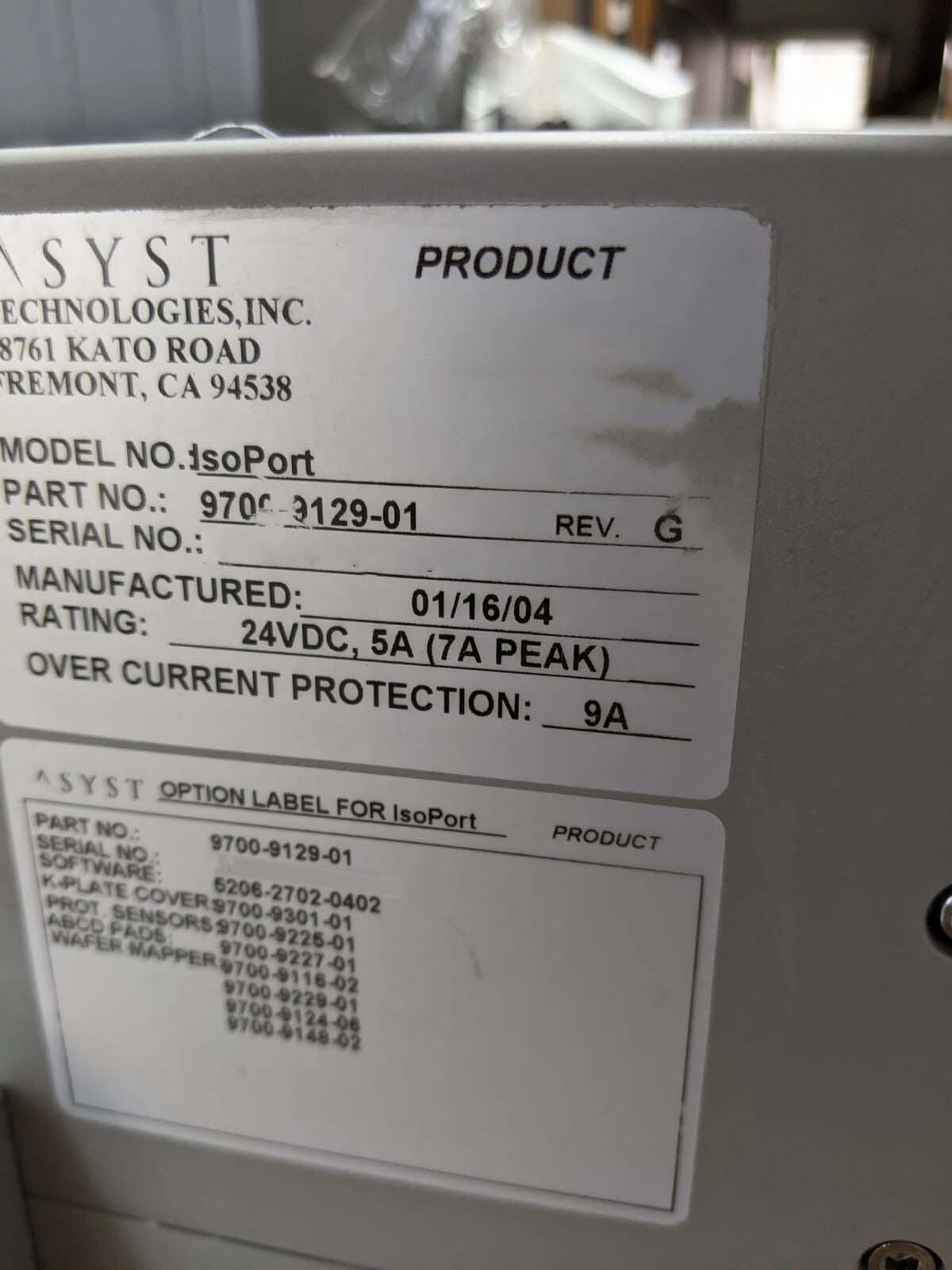

Used ASYST IsoPort #9375303 for sale

URL successfully copied!

Tap to zoom

ASYST IsoPort is a fully automated in-line front opening unified pod (FOUP) or head-in-pillow (HIP) wafer handling equipment designed to provide the ultimate in contaminant-free reliability and productivity for semiconductor wafer processing. IsoPort features a low particle environment with a set of technologies tailored to meet demanding requirements while maintaining utmost cleanliness of the wafer surface. ASYST IsoPort's pneumatically closed door minimizes dissipative particle generation, while an advanced air filtration system, including a self-cleaning, automatic filter-exchange unit and air-locks for every chamber, minimizes particle ingress. IsoPort also has a linear conveyor-dissphase arm machine designed to provide gentle handling of wafers and reduce impact of particles, allowing wafers to travel smoothly from station to station along the linear conveyor. ASYST IsoPort also comes equipped with Contaminant Monitoring Systems (CMS) that are designed to verify the cleanliness of cleanroom air systems, monitor for particles created during transfer, and measure semiconductor cleanroom particle counts. IsoPort also features several unique isolation technology tool, such as an LAFI (Locally Aggressive Filtration Isolation) asset, a low pressure particle filter, and an automated particle biasing model. These features reduce particle counts, reduce particle sticking, and increase wafer cleanliness. It is also equipped with a full suite of advanced software systems that monitor, control, and optimize wafer handling and transfers. The software includes a equipment wide communications network, centralized process and parameter management, robotic and conveyor control, bar code readers, and touchscreen interfaces. ASYST IsoPort was designed to be a reliable and efficient wafer handling system bridge the gap between front-end and back-end applications to optimize wafer transfer processes, reduce wafer movement time, enhance yield and profitability, and increase environmental compliance. It is the perfect tool for semiconductor manufacturing operations which require ultimate particle control, high throughput and maximum flexibility.

There are no reviews yet