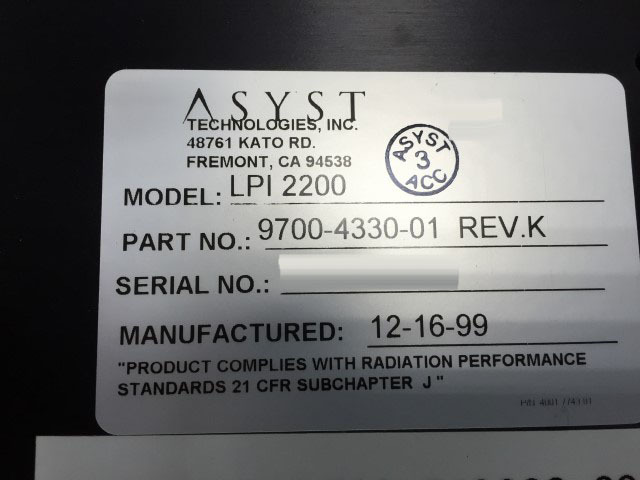

Used ASYST LPI 2200 #9111911 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ASYST LPI 2200 is a high-performance wafer handler designed to operate in a wide range of environments. It has a modular design which allows for a comprehensive and customisable equipment configurability. LPI 2200 is capable of handling a variety of wafer sizes up to 200 mm diameter in a low-pressure environment, providing precise wafer control and precise alignment. Its precise control system feature offers zoom and rotation control for accurate alignment, together with specific alignment to substrate features for precise placement. ASYST LPI 2200 features an auto-parenting function which allows for multiple wafers to be aligned simultaneously to a specific reference location. This helps to ensure precise alignment and positioning accuracy of the wafers. The handler also utilises a patented wafer clamp unit which controls wafer stability and minimises wafer breakage. The wafer clamp is highly sensitive, accurately controlling the motion of the wafers, while providing precise and repeatable motion of the wafers during travel. The handler is designed to work alongside different process requirements and is suitable for various applications. It is capable of working with a wide range of materials such as Si, GaAs, Ge and CdS. It can also be used for die bonding, bump creation, interposer attachment, wirebonding and other operations. LPI 2200 is equipped with built-in scanners and vision systems, providing a reliable and secure process monitoring. This makes it possible to detect wafer alignment problems quickly, minimize the risk of wafer breakage, and reduce waste. ASYST LPI 2200 also features a state-of-the-art Human Machine Interface (HMI), which provides users with intuitive menus and powerful data management capabilities. In terms of safety and reliability, LPI 2200 is fitted with a variety of sensors that monitor temperature, pressure and inertion levels. It also has leakage sensors to detect any hazardous gases. The handler is compatible with standard safety safety standards including ANSI, CE, and SGS. Overall, ASYST LPI 2200 offers unsurpassed precision and reliability in wafer handling. Its modular design and advanced wafer control features can provide a comprehensive and reliable process for handling wafers. With the included HMI and many safety features, it offers a comprehensive, efficient, and secure wafer processing machine.

There are no reviews yet