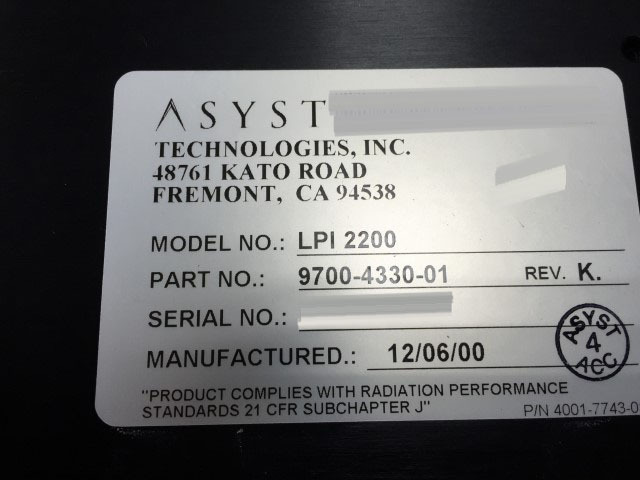

Used ASYST LPI 2200 #9111912 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ASYST LPI 2200 is a high-performance wafer handler, designed to provide efficient and precise handling and transport of 200 mm wafer and 300 mm flat panel plates. It is designed to quickly and accurately transfer wafers between wafer probers, test stations and other various tools. LPI 2200 features a flexible robot arm that can move and rotate in three axes, enabling precise wafer transfer in any direction. The highly advanced handling equipment incorporates a precise shuttering, positioning and alignment system. This ensures precise and accurate movement of wafers to and from the robot arm, eliminating any human interference. The robot arm can also be equipped with optional high-quality parallel end effectors for improved wafer handling and transport. ASYST unique patented Active Auto-Load and Unload (AALU) Unit delivers precise and precise wafer transport without the need for user intervention. The AALU Machine also reduces downtime during wafer transfer, and helps to minimize wafer contamination and breakage. The tool also features integrated safety features such as manual override, safety interlocks and safety doors, allowing operators to perform manual maintenance and repairs safely and securely. ASYST LPI 2200 is manufactured using the latest, high-tech materials, providing superior strength and stability. In addition, the unit utilizes reliable and accurate original accessories and parts to ensure maximum precision and robust cycle times. The asset runs on ASYST advanced, proprietary UltraST software, ensuring comprehensive model performance and flexibility. Comprehensive reports, data logging and configuration options can be accessed by the user on the easy-to-use graphical user interface. The equipment is also equipped with a wide range of built-in diagnostic tools, enabling rapid troubleshooting and avoiding costly downtime. The UltraST software also ensures reliable and advanced traceability and process control. Finally, LPI 2200 is available with a range of customized options, allowing it to be tailored to the specific needs of customers. Options include improved quench cooling, integration of custom sensors and more. Its versatile design makes it a great choice for customers looking for an efficient and reliable wafer handler.

There are no reviews yet