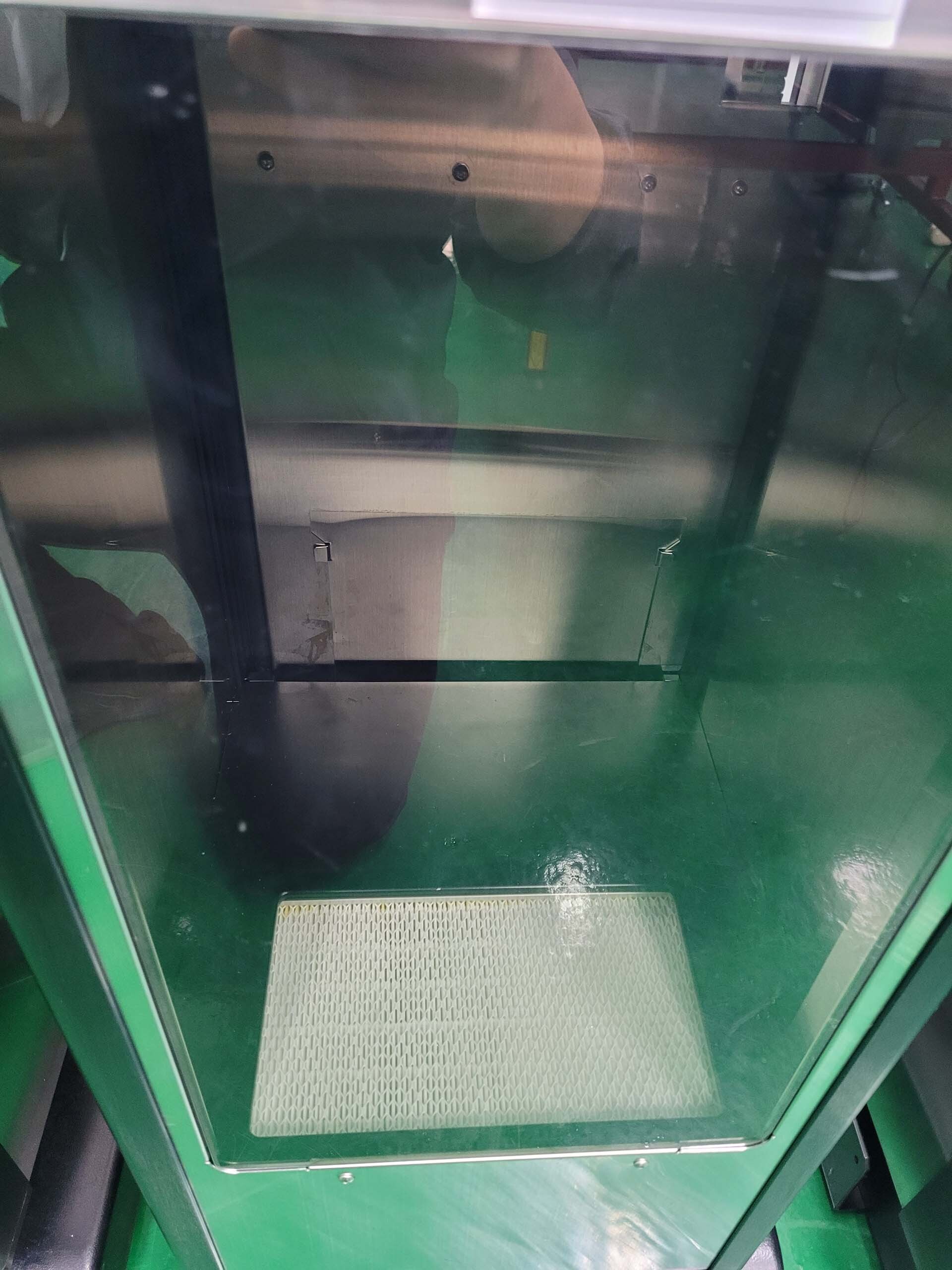

Used ASYST LPT 2200 #293603135 for sale

URL successfully copied!

Tap to zoom

ASYST LPT 2200 is a wafer handler designed to move wafers between process and storage cassettes. It is designed to enable wafer sorting, kitting and screening by non-contact scanning, in order to maintain the highest level of priority for wafer cleaning and contamination control. The equipment is equipped with a fully automated and integrated service function, which helps to reduce the total system downtime and maintenance cost. ASYST LPT2200 features an all-in-one design, combines multiple functions. The single-stage device transport unit allows for handling of both flat, round and non-flat wafers with a diameter ranging from four to twelve inches in a high-speed fashion. It is also equipped with an operating temperature range from 8°C to 50°C and a Class 1.0 cleanroom rating. The wafer handler is designed with modular components that can be easily configured according to the specific needs of your operation. Its patented FlexD modulation technology provides precise positional accuracy and high throughput, while the automated displacement and speed monitoring function ensures safe and reliable handling of wafers. LPT 2200 is designed with a dual-layered SMEMA interlock and an electronic enclosure that provides secure access. Its advanced FIS (Fiber Input Machine) provides consistent, reliable input to its optical performance. Its real-time vacuum load port ensures continuous loading and unloading, while the die-tilt T-mask-E is used to mask out inactive slice in the substrate. The wafer handler also features FC-compliant communication with the host device, enabling functionality and protocol flexibility. Its MES-compliant communication facilitates efficient information exchange between wafer array and factory systems. Its extreme flexibility and scalability is ideal for low to high-volume production environments. In addition, LPT2200 is engineered with a vision tool, which includes a light source, camera and optical filters, to ensure accuracy and high throughput. The double-stage asset provides the highest throughput in the shortest amount of time. Its built-in model redundancy and diagnostic tools provide continuous monitoring of the equipment and helps to detect any system error. In conclusion, ASYST LPT 2200 provides an efficient wafer handling unit that is designed to meet the needs of high-volume production environments while maximizing cleanroom safety and efficiency. This versatile and cost-effective wafer handler is ideal for semiconductor fabrication processes and offers a range of features and benefits to ensure successful and reliable wafer processing.

There are no reviews yet