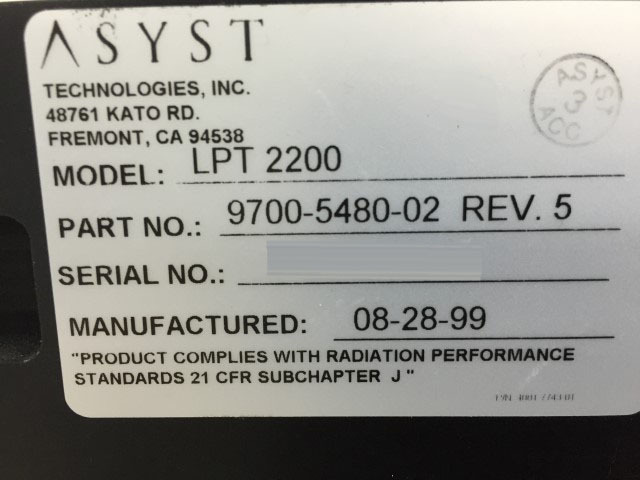

Used ASYST LPT 2200 #9111904 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ASYST LPT 2200 wafer handler is an automated, self-aligning equipment designed for use in the semiconductor industry. The system is designed to move, align, and transport wafers, cassettes, and FOUPs from input to output racks. It also features a fully open architecture, allowing for compatibility with all sorts of process systems, materials handling solutions, and robotics. ASYST LPT2200 is available in three sizes—the 1200M, the 1400M, and the 2100M—with each corresponding to a different size of wafers. Its powerful, dual axis motion unit allows for fast and precise positioning of the wafers and can handle different diameters, thicknesses, and weights. The unit is equipped with a vision machine, automated centering tool, and long-term calibration algorithm. This enables it to adjust and optimize its performance on the fly to any wafer or condition. The asset is extremely reliable and robust, built with a stainless steel monoblock frame and heavy-duty motors that can operate continuously in high-temperature, high-humidity conditions. It uses a thermal/mechanical vacuum model to precisely align and mount the wafers, and is designed to minimize dislocation and potential damage. The software interface of LPT 2200 is flexible and user-friendly, providing a range of options for configuration and operation. It supports remote diagnosis and maintenance, enabling the user to diagnose issues within the equipment and make adjustments over the network. Safety is also a key design feature of LPT2200. It utilizes a number of safety features, including emergency stop buttons and a light curtain perimeter monitoring system to ensure operator safety when loading and unloading wafers. Overall, ASYST LPT 2200 is an advanced and reliable wafer handler with a robust, flexible design. It is a reliable tool for use in the semiconductor industry and offers exceptional performance, reliability, and safety.

There are no reviews yet