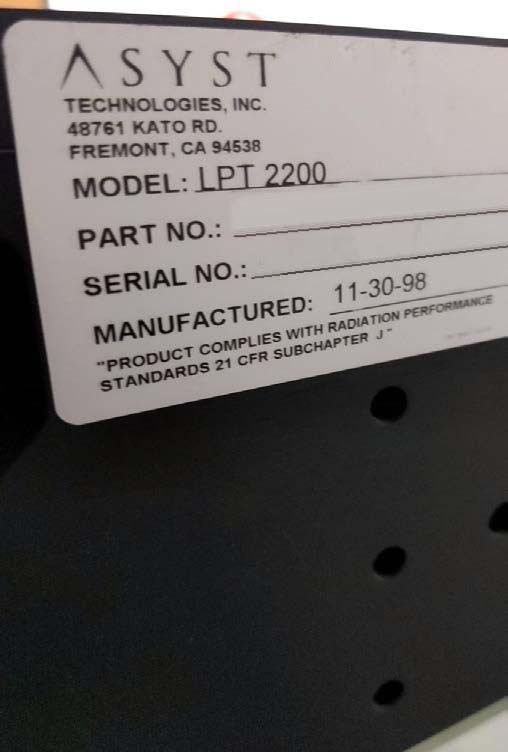

Used ASYST LPT 2200 #9384482 for sale

URL successfully copied!

Tap to zoom

ASYST LPT 2200 is a highly reliable wafer handler which is designed to transport and accurately position both 200mm and 300mm semiconductor wafers in cleanroom environments. The device is comprised of two main components; the wafer transport interface cabinet, which controls the picking and placing of wafers onto a wafer tray, and the wafer transport sub-system, which houses the mechanism which drives the wafer transport stage, as well as temperature, humidity and particle monitors. ASYST LPT2200 employs the use of an electrically driven stepping motor, belt driven, programmable micro stage, as well as a three-axis, closed-loop joystick control system to accurately position wafers within the device. The device is also equipped with a programmable positioner, with sensitivities ranging from 1.26um to 5um and with a repeatability of +/- 2.5um, resulting in very precise and accurate positioning of wafers when the device is in use. LPT 2200 is designed to be able to transport wafers in tray sizes that range from 4" to 9", or 200mm and 300mm wafers, with a holding capacity of up to 6 wafers at a time. It is also designed for two wafer-to-wafer configurations, which allow for easy transfer of wafers from tray to tray without any manual intervention. The device also contains an electro-pneumatic isolation valve, which functions as an air shield between different process equipment. This air shield helps to prevent contamination build-up by providing a clean and controlled environment in which the device can operate. Furthermore, the device has been specifically designed to operate at a maximum temperature of 41°C and humidity of 20-60%. This means that it is suitable for use in a variety of cleanroom environments, and can even be used in hazardous areas such as Class 10 and Class 100 cleanrooms. In conclusion, LPT2200 is a highly reliable and accurate wafer handler, perfect for use in cleanroom and other high-precision environments and applications. With its three-axis control system, temperature, humidity and particle monitoring, as well as its belt driven, programmable micro stage and electro-pneumatic isolation valve, it is designed to transport and accurately position semi-conductor wafers and provide superior performance.

There are no reviews yet