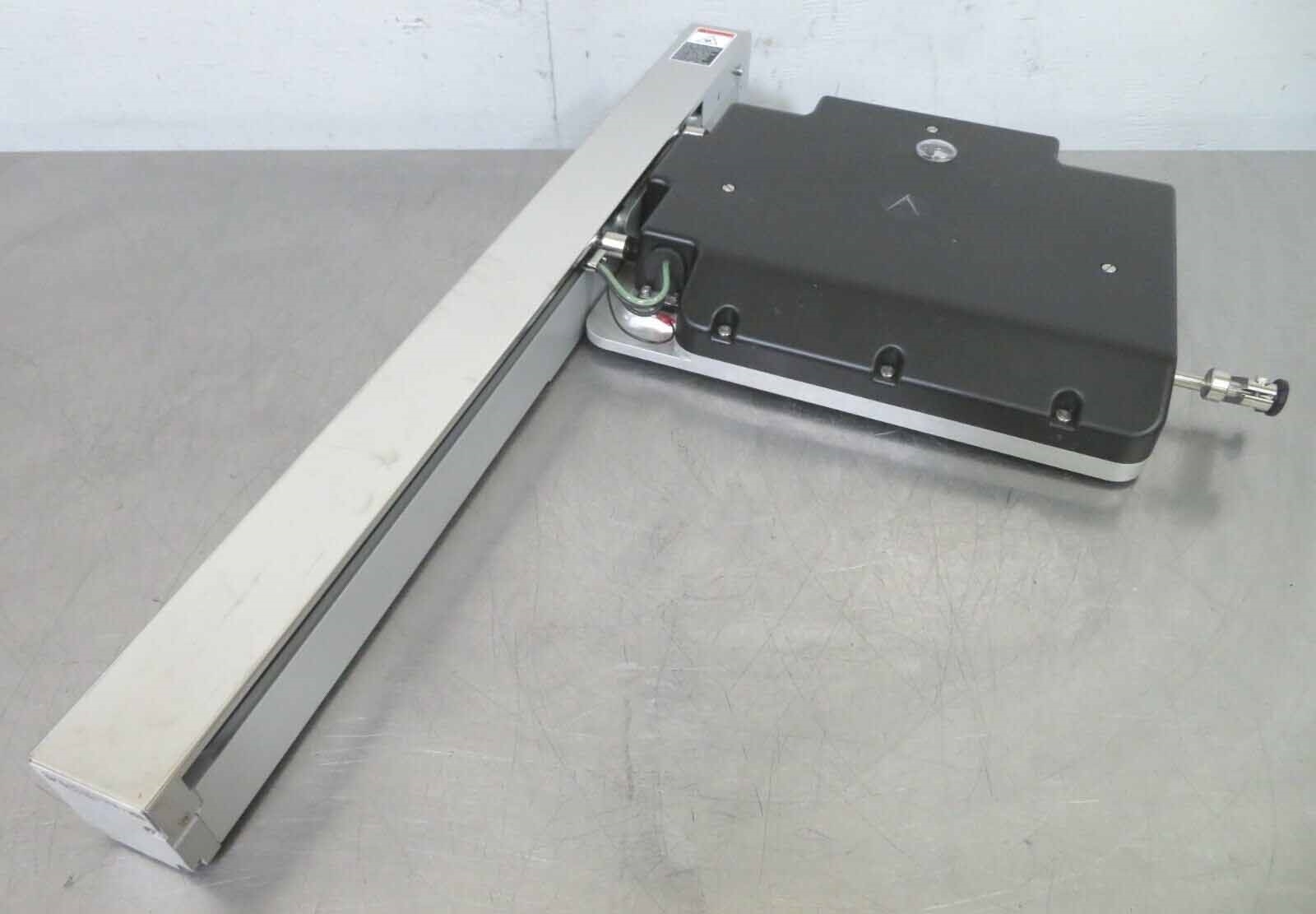

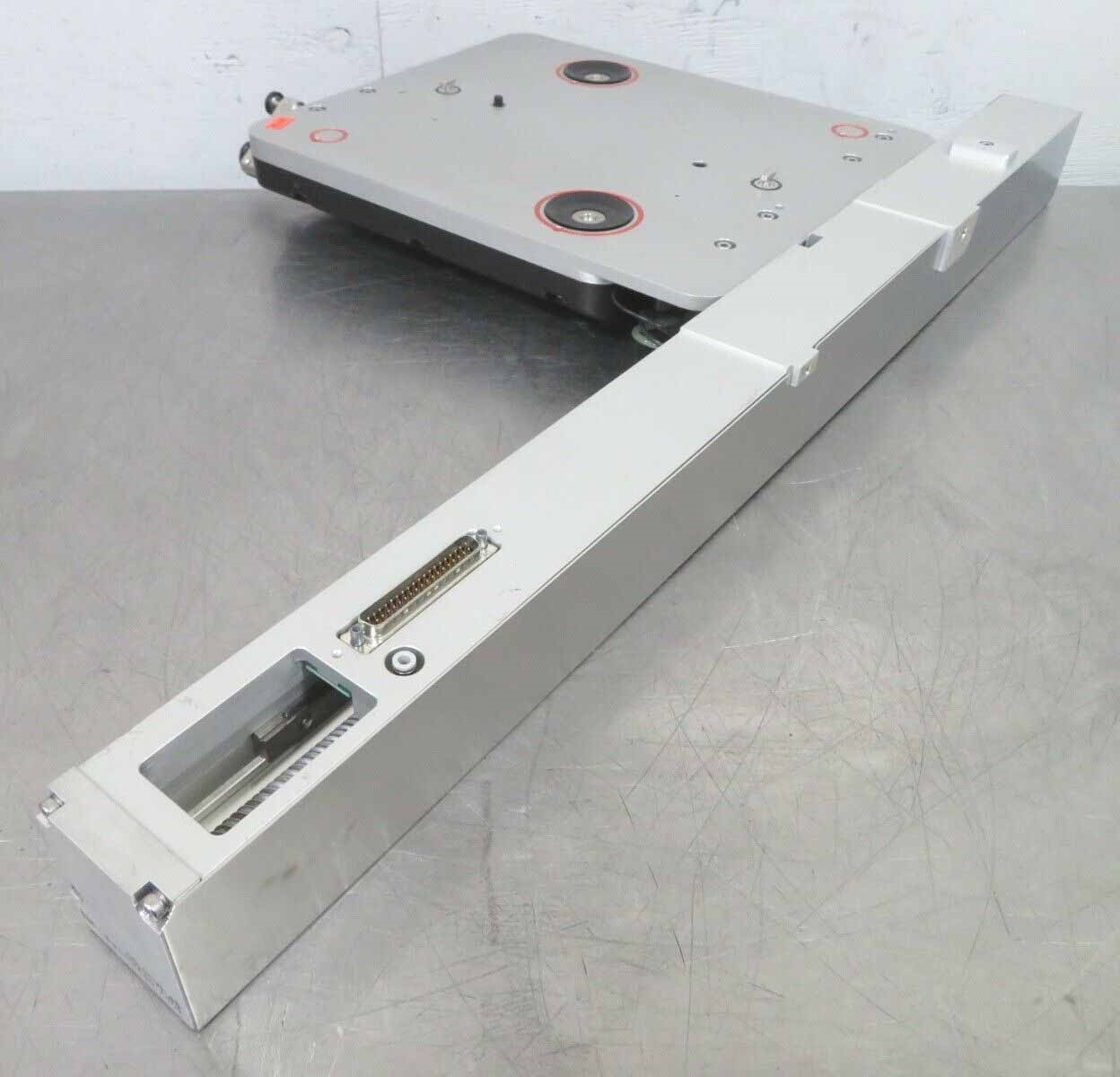

Used ASYST SP1MG0100 #9278792 for sale

URL successfully copied!

Tap to zoom

ASYST SP1MG0100 is a multi-functional automation wafer handler designed for the transport, testing, and cutting of silicon and other wafer materials. The handler features a compact and modular design consisting of multiple stages, allowing for efficient interchangeability and flexibility in production. The handler has a main carry stage that comprises all of the mechanisms used to transport wafers between the equipment's input and output. Additionally, the handler has clamp and swab stages for cleaning and removing foreign substances from wafer surfaces. SP1MG0100 is also equipped with a test/cut stage, which features two blades mounted over a force-sensing platform. This combination allows for precision cutting of individual dice from a wafer with a maximum accuracy of 25 um. The handle can also perform resistivity tests and scanning electron microscopy on the individual die pieces. The handler is also equipped with a vacuum system that can be independently controlled and calibrated for different wafer materials. This vacuum unit is designed to ensure that the wafers stay firmly attached to the clamping vacuum cup throughout the production process. The handler also comes with a wafer lifting machine for easy positioning of wafers. Finally, ASYST SP1MG0100 uses advanced robotics and vision-tracking technology to maximize wafer throughput. This tool allows for rapid transport and manipulation of wafers, while its machine learning capabilities enable it to further optimize production, based on the data it gathers from previous production cycles. Furthermore, the handler's modular design makes it both space and cost-efficient. In summary, SP1MG0100 is a highly advanced, multi-functional wafer handler designed for the testing and cutting of silicon and other wafer materials. Its various features, including a main carry stage, clamp and swab stages, test/cut stage, wafer lifting asset, and advanced robotics and vision-tracking technology, enable it to achieve optimized production while minimizing waste. This makes ASYST SP1MG0100 an ideal option for wafer-processing applications.

There are no reviews yet