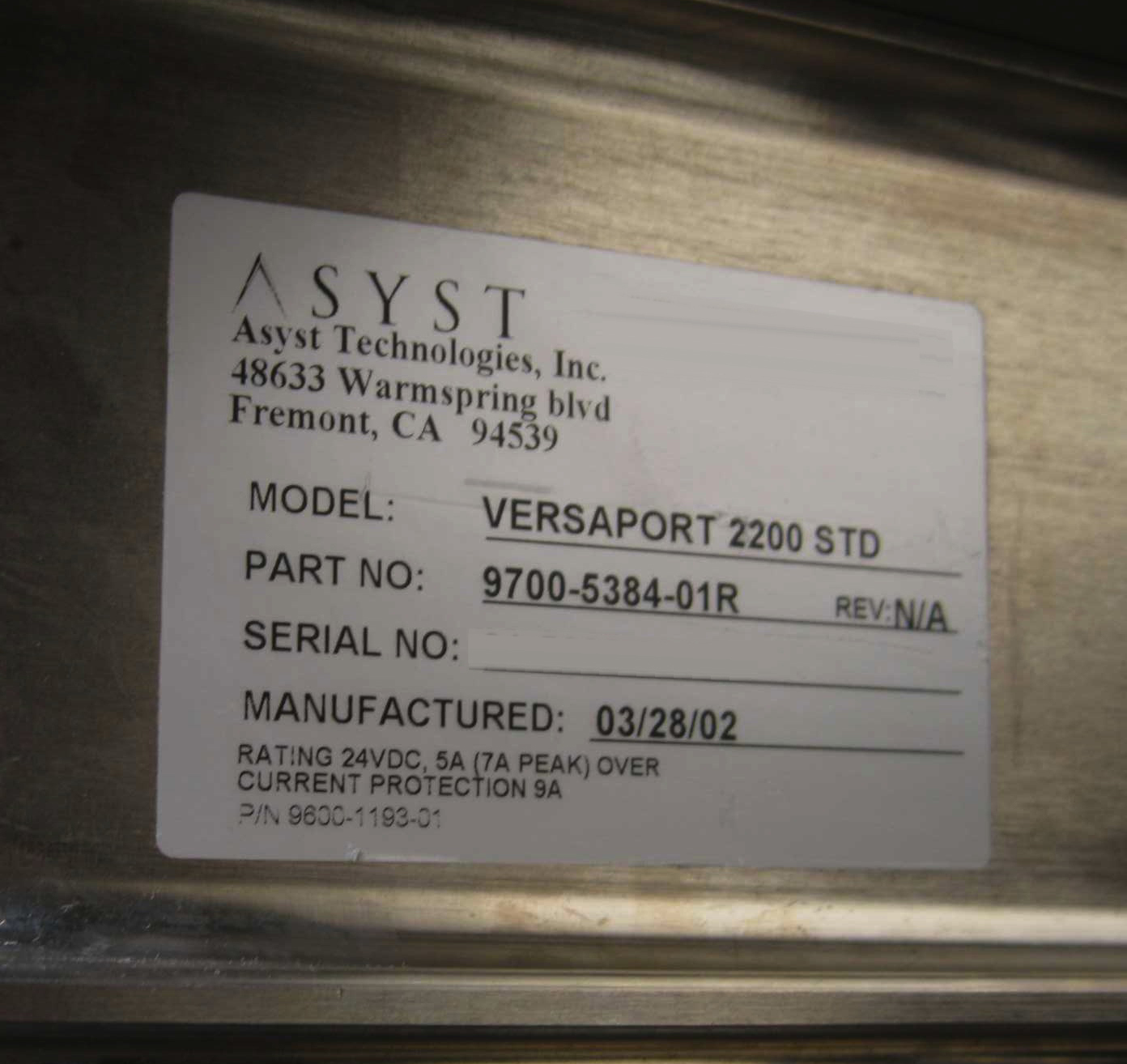

Used ASYST VersaPort 2200 STD #9043893 for sale

URL successfully copied!

Tap to zoom

ASYST VersaPort 2200 STD is a wafer handler, designed for high precision robotic wafer loading and unloading. It is capable of handling a variety of wafer sizes from 2" up to 8" on cassette carriers with 25 mm height. This automation platform enables users to create custom workflows to transport wafers within a process cell. Its advanced robotic motion control technology allows for wafer centering accuracy of +/- 0.03 mm, with speed of up to 0.35m/sec. It has a built in "run on short" feature which enables users to quickly adjust robot motion paths to compensate for short wafer or cassette size errors. This guarantees successful wafer transfer during operations. Its reliable and maintainable design ensures accurate and repeatable robotic motion as well as minimal downtime. Safety interlocks are built into all its component parts to protect user and equipment from potential contamination. An optional gas purge system helps to maintain the cleanroom environment by providing a protective gas barrier during loading and unloading. The VersaPort 2200's unique design allows it to operate in the smallest footprint within a wafer fab environment. It includes two motorised linear robot arms, a wafer cart and a support frame. The two robot arms move along a linear rail in both the x and y axis at the same time. Data logging and traceability are also provided with the optional Data Acquisition Interface. In order to guarantee high levels of performance, the VersaPort 2200 is designed for quick and easy installation while reducing maintenance costs. It has built in pumps which provide pneumatic energy for vacuum coupling with the wafer for reliable wafer centering and handling. All components have dust and water protection to ensure reliable operation in harsh environments. In summary, VersaPort 2200 STD is a high performance wafer handling system featuring advanced robotic motion control technology and built in safety features. Its interoperability with existing fab process and equipment allows for a faster time to market and lower cost of ownership. High wafer centering accuracy, reliable operation and long life design make the VersaPort 2200 the ideal choice for wafer manufacturing.

There are no reviews yet