Used BACCINI / AMAT / APPLIED MATERIALS MAM001000018 #9361537 for sale

URL successfully copied!

Tap to zoom

ID: 9361537

Vintage: 2011

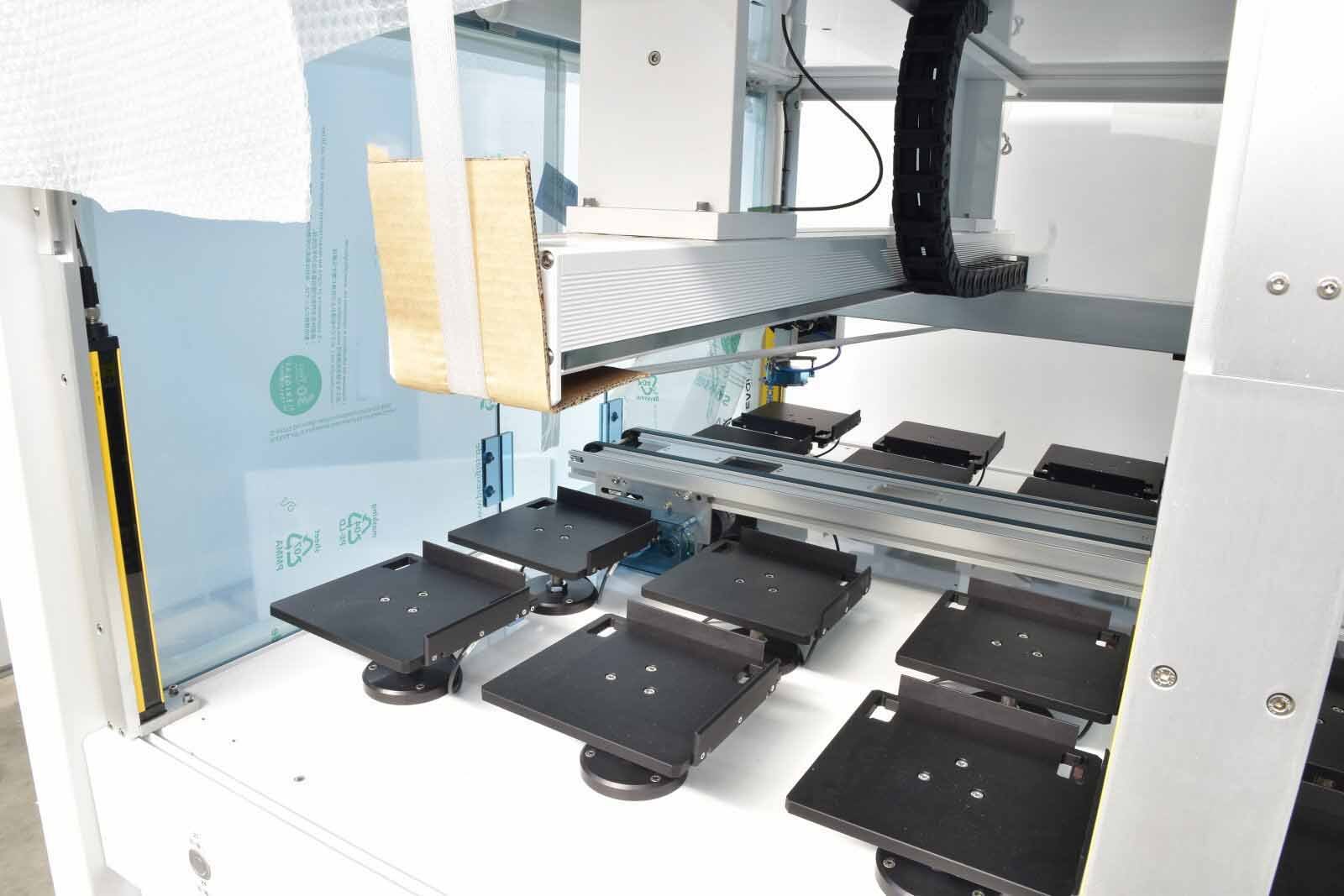

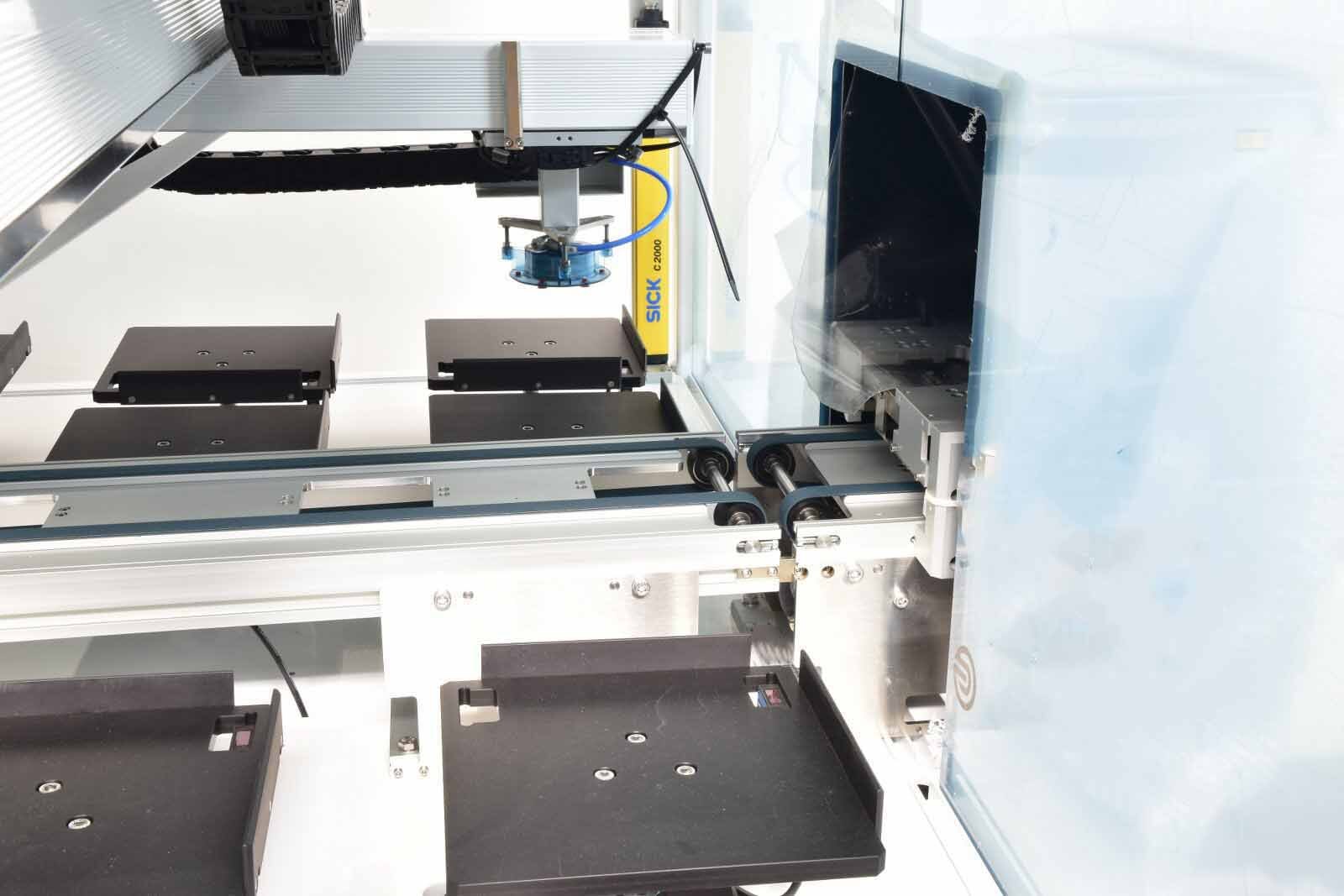

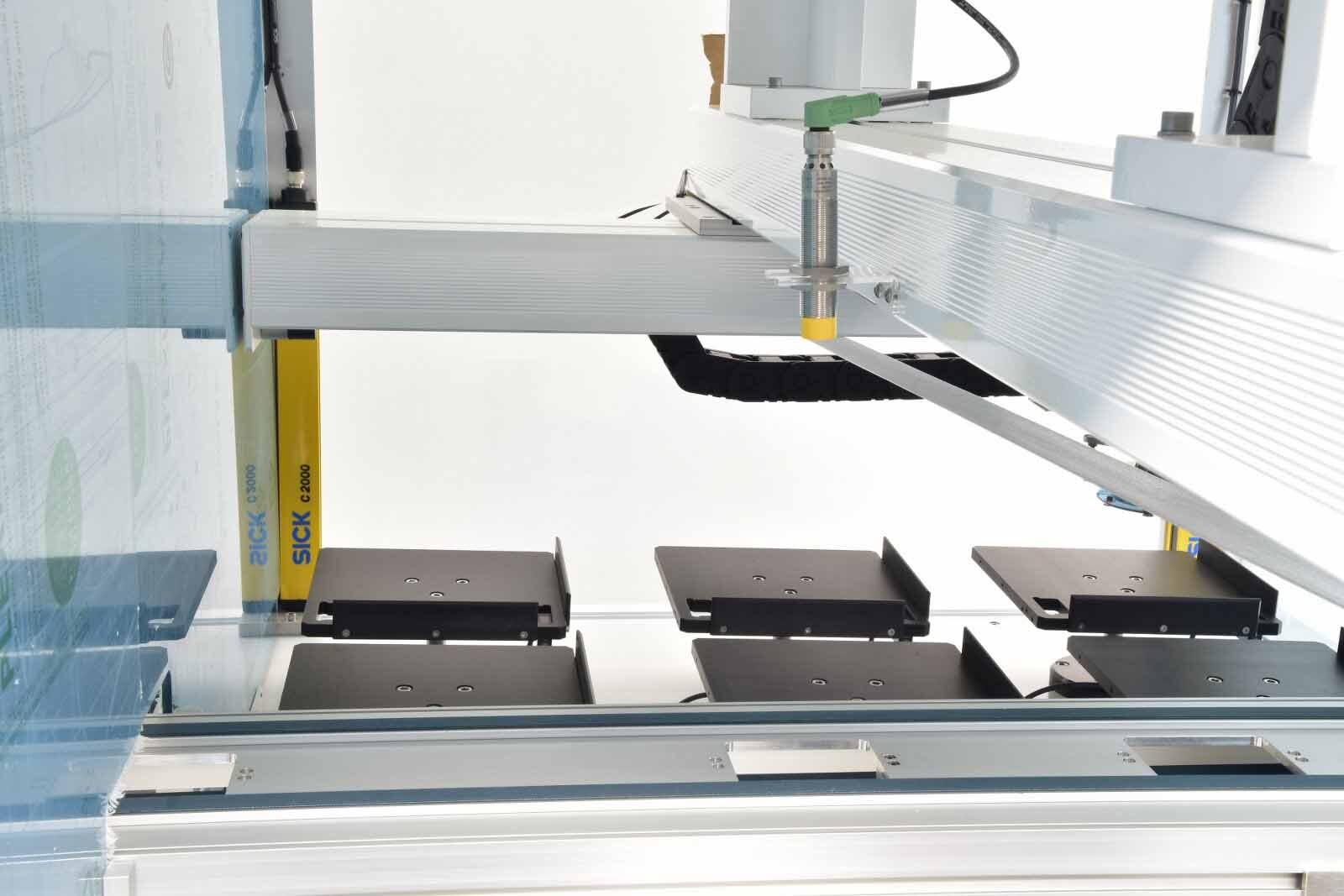

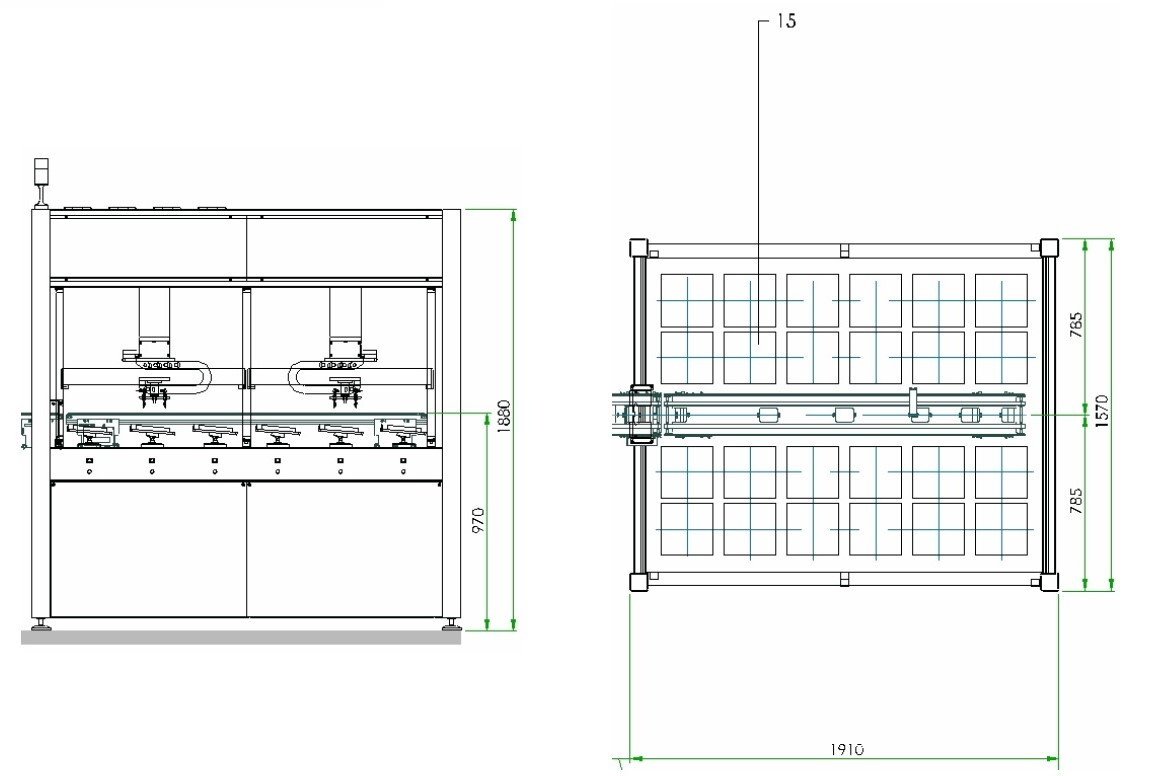

Sorter

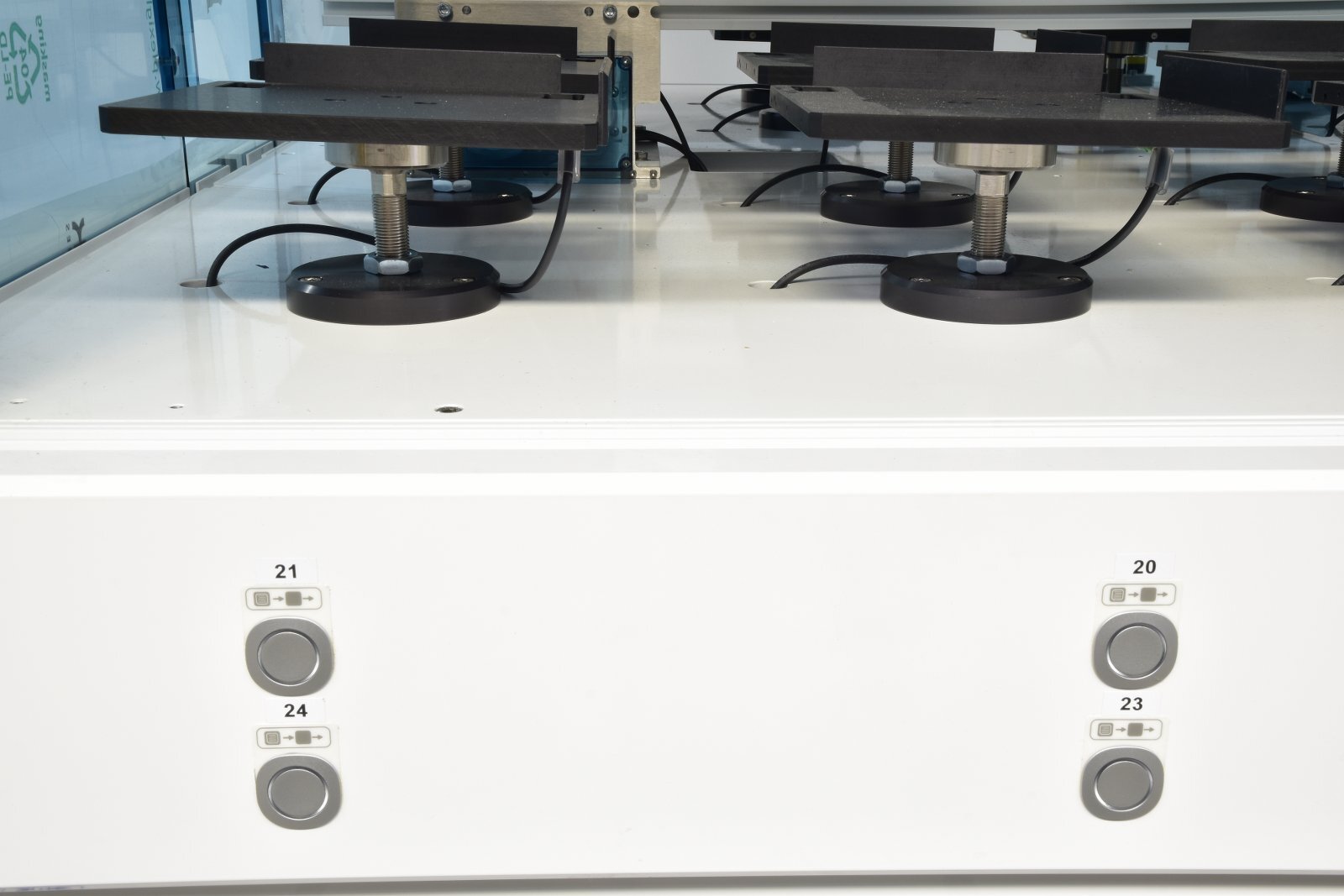

24-Positions

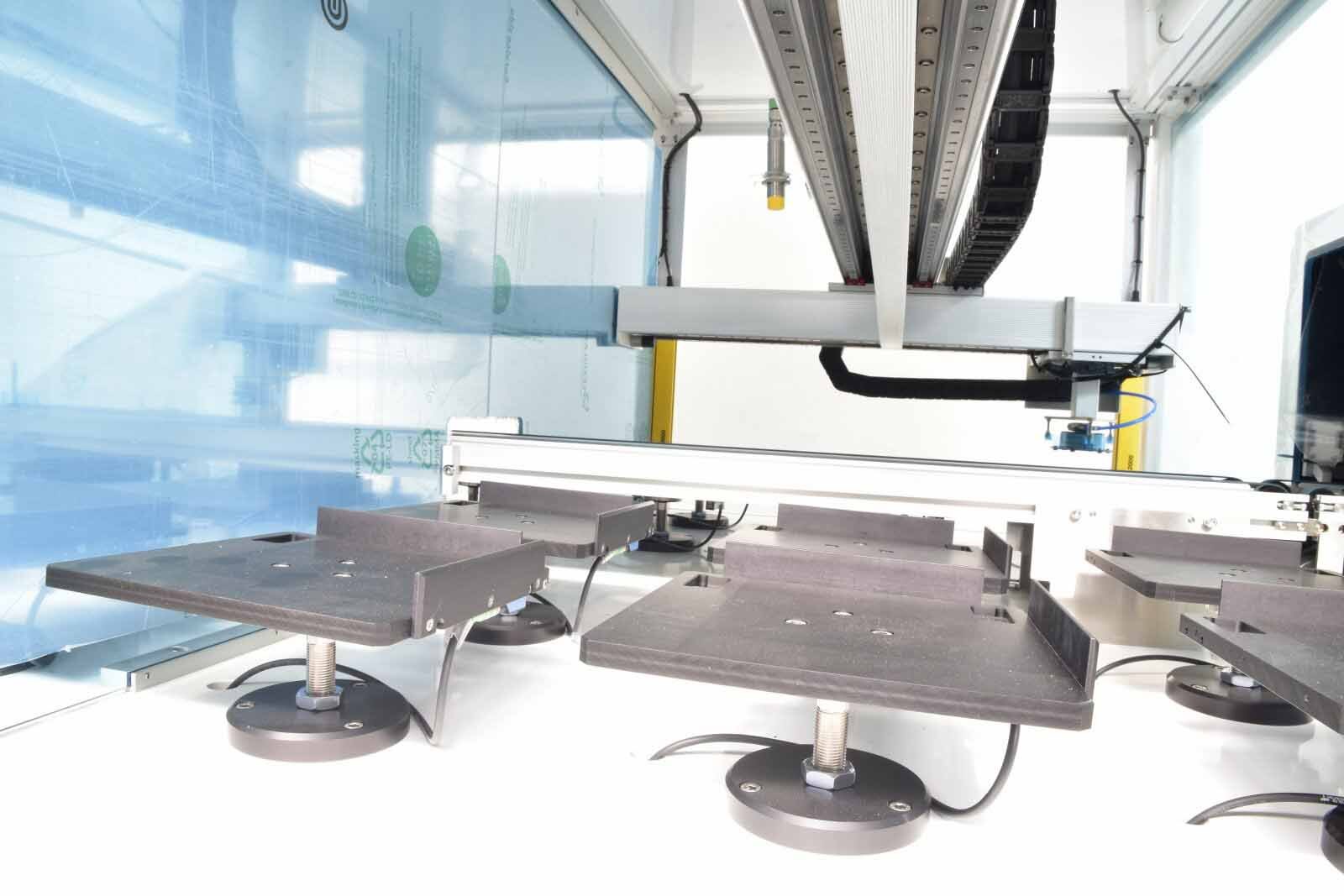

Sorting module: (24) Containers

Manual loading and unloading

Line type: Inline

(3) Clusters

Maximum capacity: 1,350 Wafers / hour

Throughput: 1,250 Wafers / hour

Operating time: 95%

Breakage rate: 0.2%

MTBF: 500 Hours

MTTR: 3 Hours

Wafer alignment: Front upwards Noise

Level: 70 dB

MES Connection:

Interface: SECS / GEM

Minimum temperature: 20°C

Maximum temperature: 24°C

Minimum relative humidity: 40%

Maximum relative humidity: 60%

2011 vintage.

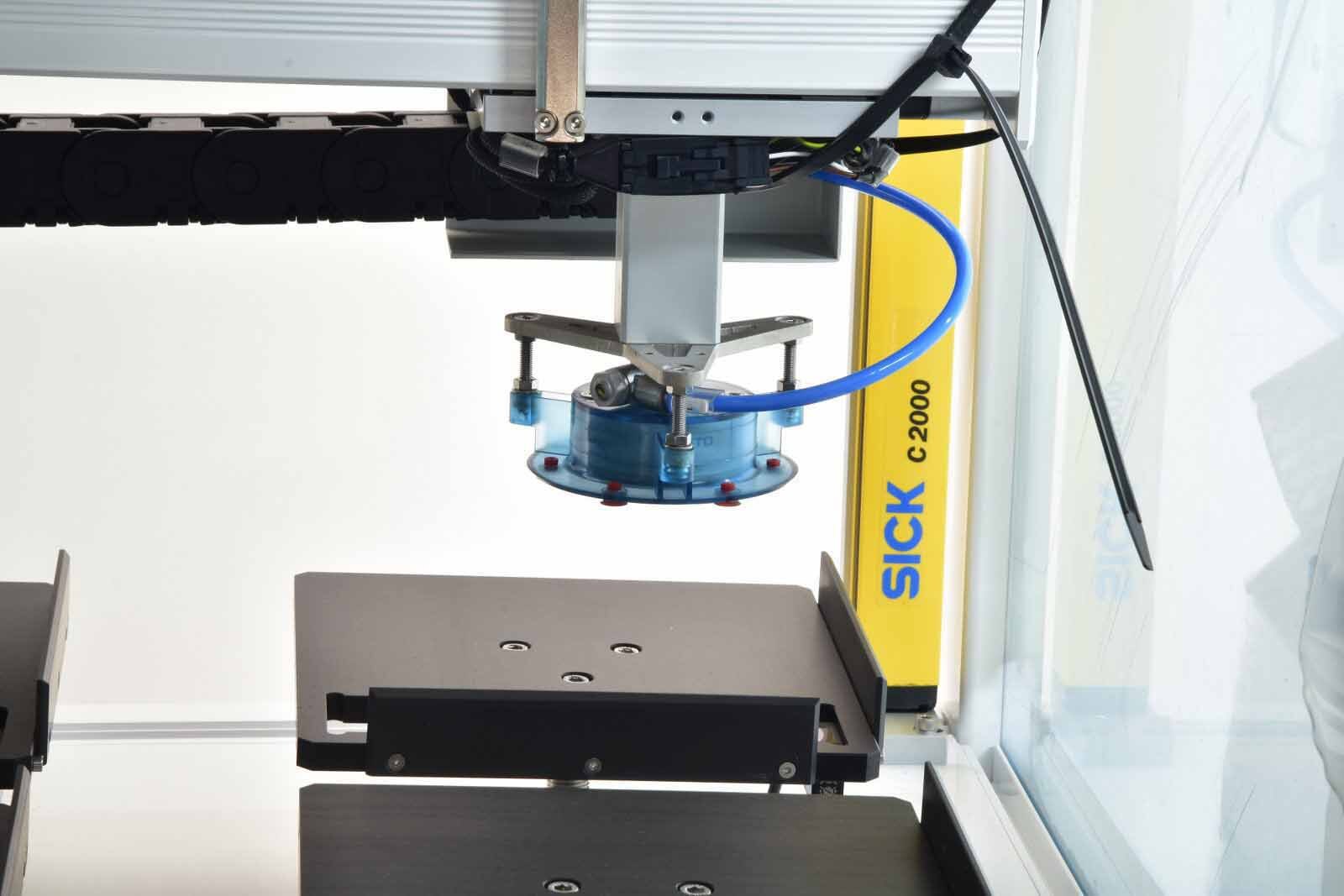

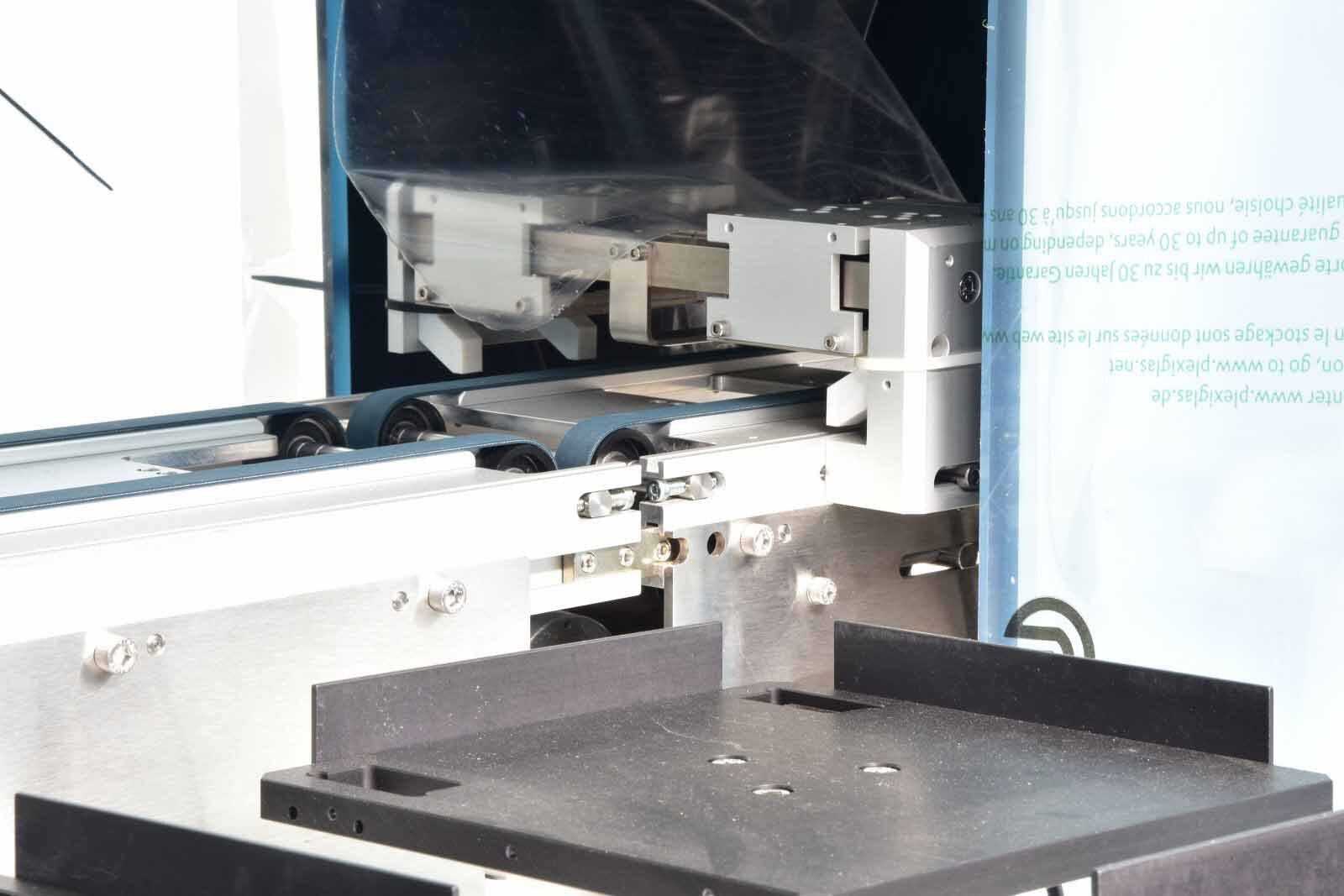

BACCINI / AMAT / APPLIED MATERIALS MAM001000018 wafer handler is an automated device designed to precisely handle and manipulate wafers in semiconductor fabrication facilities. It is designed with a high-performance motor and belt drive equipment, as well as a control system configured to maximalize the speed of production while still adhering to appropriate safety protocols. These components, paired with the handler's robust construction, make it a top choice for highly-advanced semiconductor fabrication tasks. AMAT MAM001000018 uses a unique clamping unit and a series of pneumatic motors to pickup wafers of various sizes from a cassette source, and transfer them onto a desired processing machine. It can handle up to 18 wafers at a time, and is capable of reliable and repeatable motion up to a speed of 125 mm/sec. Additionally, it provides precise positioning of the end effector location, allowing for precise control of the wafers. It is also designed with convenience and flexibility in mind, featuring an intuitive GUI for easy setup and operation, as well as a variety of programming and customizing options. This machine allows for a wide range of adjustments to be made, such as changing the way the wafer is held, the acceleration and deceleration profiles, and the spin speed of the end effector. As a result, BACCINI MAM001000018 is suitable for small to medium-sized wafers as well as large ones. Finally, this wafer handler is also designed for maximum durability and reliability, thanks to its robust construction, multiple levels of mechanical redundancy, and integrated motion protection. The mechanical components and aluminum frame are designed to resist wear, corrosion, and vibration, further adding to its level of dependability. Its modular design also allows for easy troubleshooting and maintenance, and integrated air filters help extend the life of the machine even further. All in all, APPLIED MATERIALS MAM001000018 wafer handler offers industry-leading performance and reliability, making it a top choice for a wide range of precision applications. This precision handling tool is ideally suited to produce a wide range of wafer sizes and materials quickly and accurately. It achieves this with a combination of advanced components, user-friendly controls, and an impressive level of durability and reliability.

There are no reviews yet