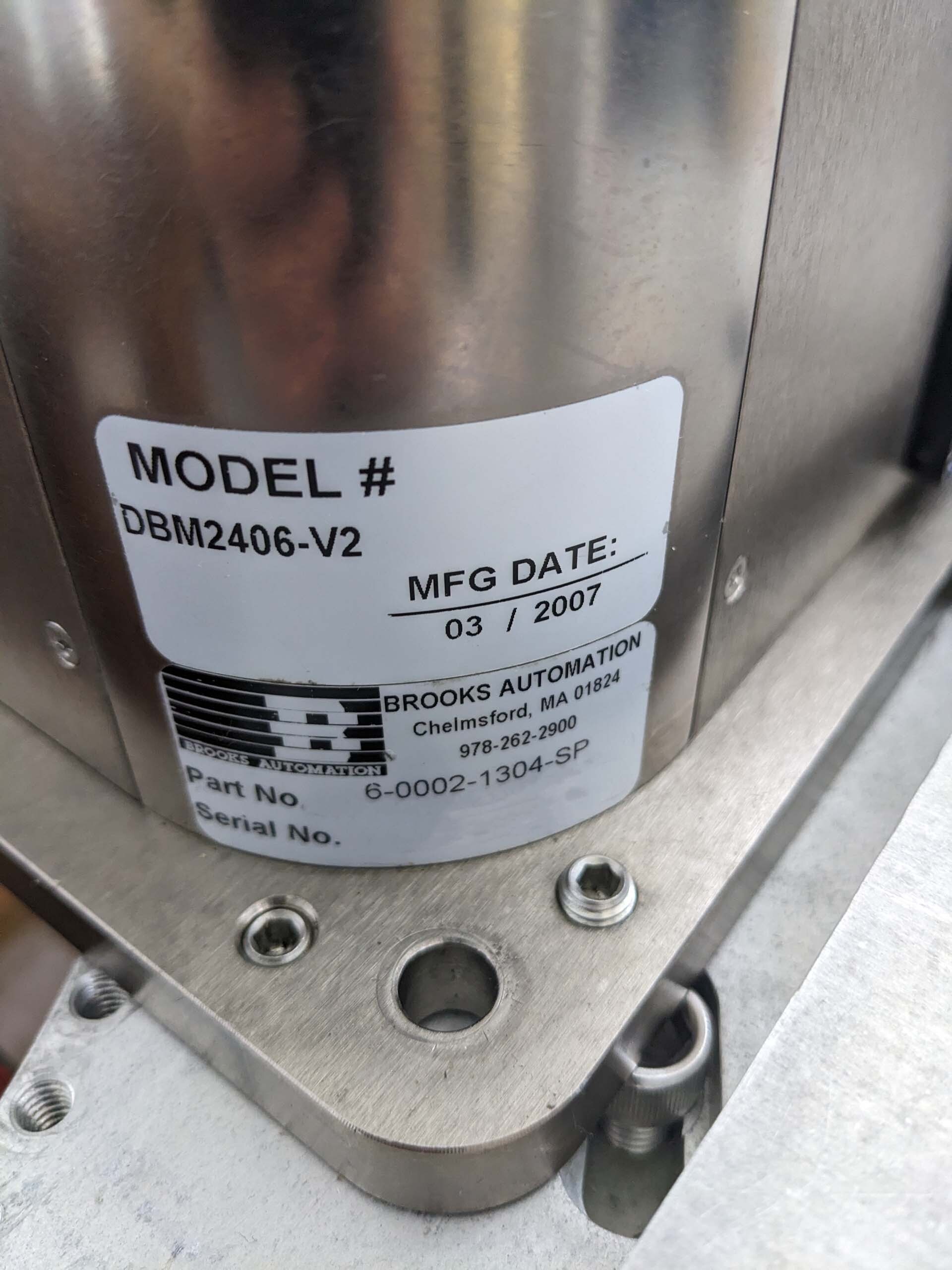

Used BROOKS AUTOMATION DBM 2406-V2 #9301902 for sale

URL successfully copied!

Tap to zoom

BROOKS AUTOMATION DBM 2406-V2 wafer handler is an advanced wafer loading and unloading device that is designed to meet the demands of today's sophisticated semiconductor manufacturing lines. It allows high throughput and precise control of wafers, whether they are good die or bad die. This automated wafer handler can process up to 240 wafers per hour, including both front- and back-side operations. It is capable of up to 200mm wafer processing, and can handle any wafer size up to 8 inches. With its advanced control equipment and high precision stepper motors, this system is able to output some of the highest throughputs in the industry. DBM 2406-V2 wafer handler is designed to provide reliable and accurate loading and unloading of wafers. The programmable loader slot offers users the ability to adjust the parameters of the loader slot for different wafer sizes and types. The motion subsystem utilizes a ball screw driven stage that can reach speeds of up to 40 mm/s. This primary characterizing unit provides precise linear motion to eight axes, enabling high throughput of wafers. BROOKS AUTOMATION DBM 2406-V2 wafer handler also features a vision machine that provides edge detection and alignment during loading and unloading, as well as an environmental enclosure to protect the tool from particle contamination. In addition to efficient and accurate wafer handling, DBM 2406-V2 wafer handler also offers users an interactive graphical user interface. This user interface allows users to control the entire wafer process from a PC or notebook computer. It provides access to a wide array of process settings including wafer orientation, temperature, speed, gap size, and many other variables. This user friendly interface makes programming the asset simple for even the most inexperienced users. BROOKS AUTOMATION DBM 2406-V2 wafer handler provides high performance and flexibility for a diverse range of products. It is designed for semiconductor production lines that demand speed, precision, and accuracy without sacrificing quality. With its advanced automation and reliable operation, this model is well suited for manufacturers to quickly and efficiently process their wafers.

There are no reviews yet