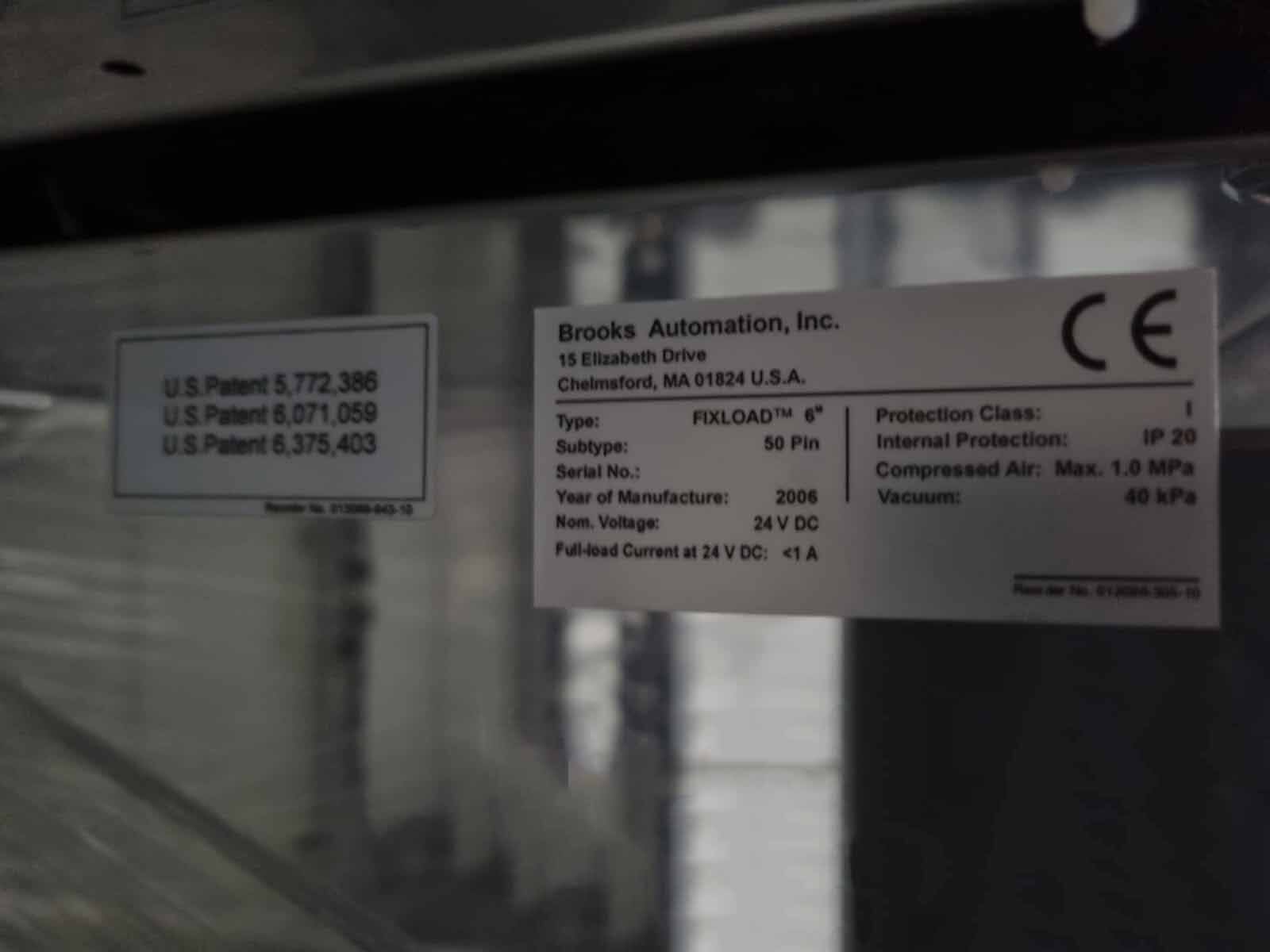

Used BROOKS AUTOMATION Fixload 6 #293626364 for sale

URL successfully copied!

Tap to zoom

BROOKS AUTOMATION Fixload 6 is a high-performance, fully-automated wafer handler designed for semiconductor manufacturing. Fixload 6 can handle wafers ranging in diameter from 100 mm to 300 mm, and consists of a main control unit and powered carousels for wafer placement and transfer. It includes an advanced, multi-pass safety equipment with dual-lock safety doors, password protection, and built-in sensors to monitor and protect the wafers being handled. Additionally, the system is designed with a Wafer Transport Module (WTM) that guides the wafer to its destination station, while the Intelliflow (TM) adaptive, real-time control technology continuously adjusts and corrects wafer paths to maximize throughput and efficiency, as well as determine when it is necessary to stop the unit to prevent wafer damage. The robust BROOKS AUTOMATION Fixload 6 also features complete traceability capabilities, including real-time recipe management, log-level accuracy, and Wafer Centric Tracking (TM) that tracks the entire life cycle of the wafer from beginning to end. Exception reporting allows operators to quickly identify any problems and recommend corrective action. The machine is powered by a high-speed controller running on an FPGA, and a highly-accurate, ultra-precise, three-axis piezo-actuator for precise and constant wafer placement. Fixload 6 includes a variety of safety and alarm features, including interlock switches, malfunction detection and reporting, and emergency stop logic. Utilizing a 3- or 4-stage wafer transfer and a high-drive, low-torque transfer arbor, BROOKS AUTOMATION Fixload 6 is designed to increase wafer throughput, while offering high levels of precision and accuracy. It also allows for quick and easy set-up and maintenance due to its user-friendly interface and high levels of automation. The end result is high-speed, reliable, precise handling of wafers with the best possible yields.

There are no reviews yet