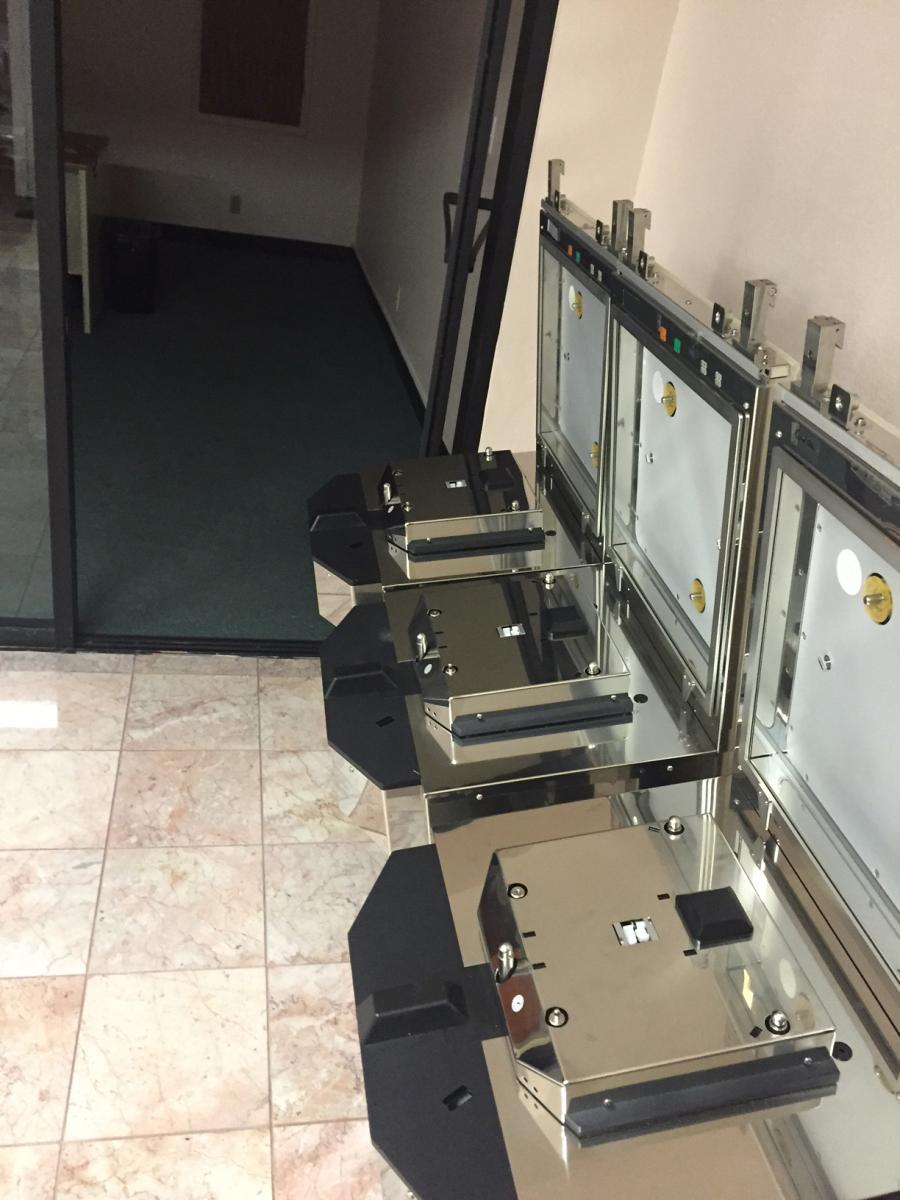

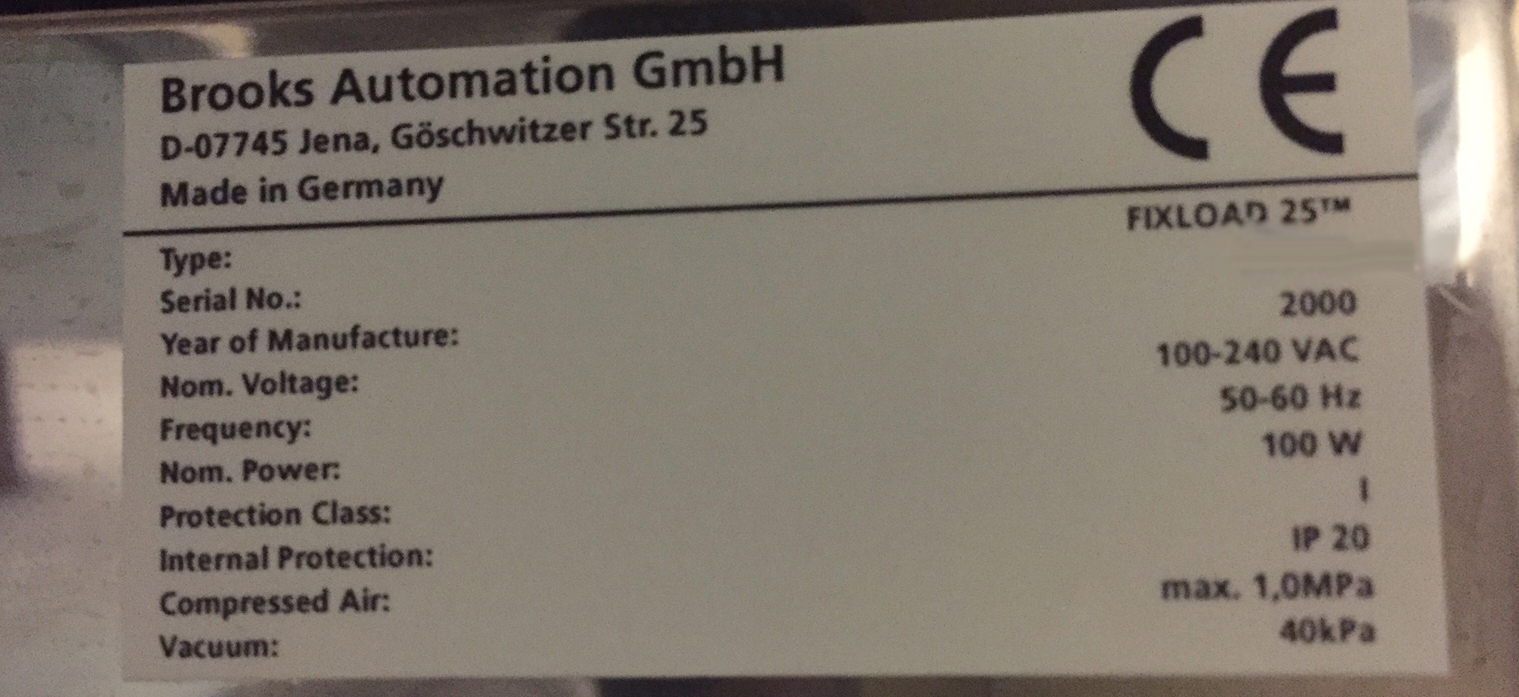

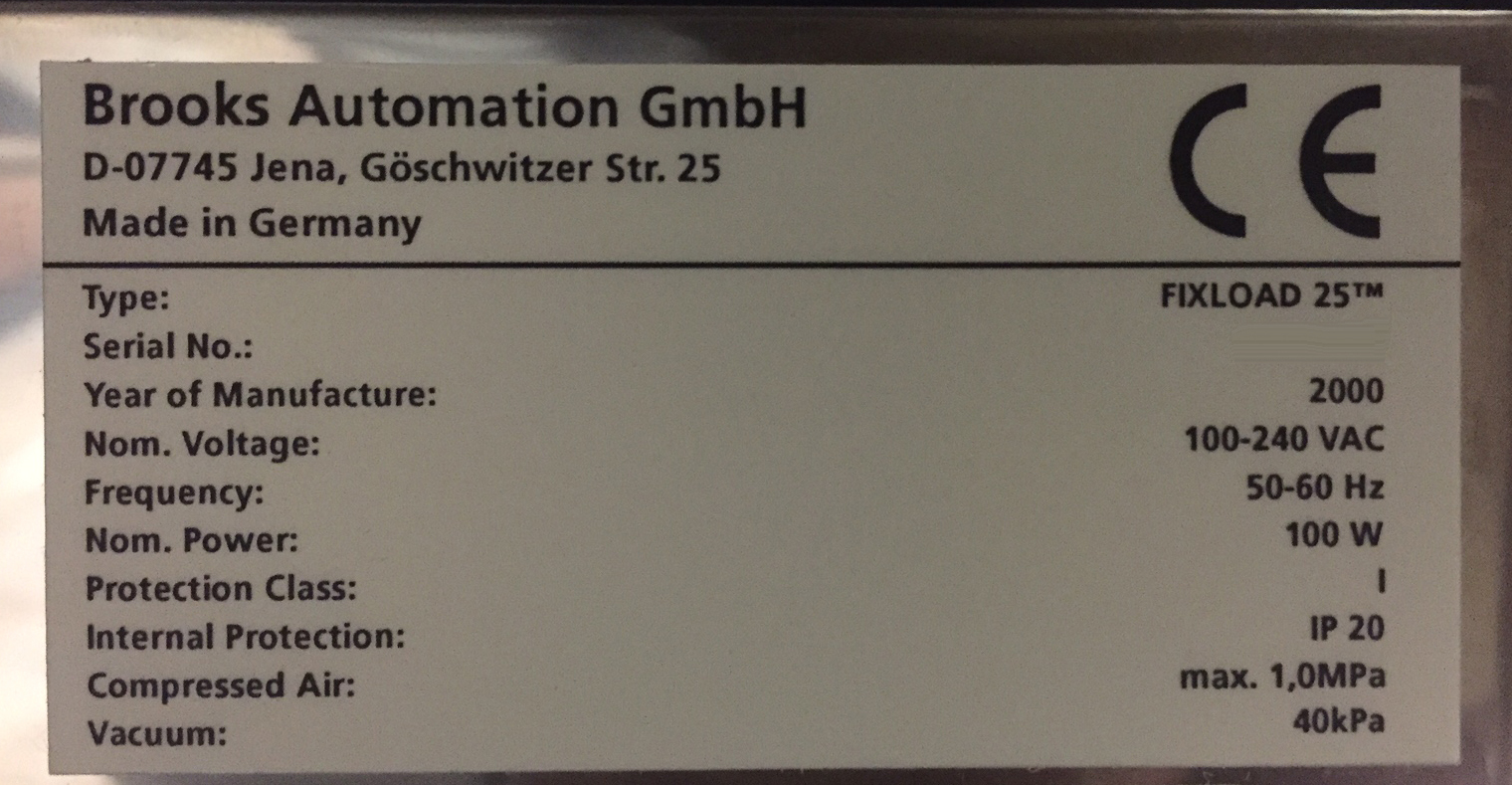

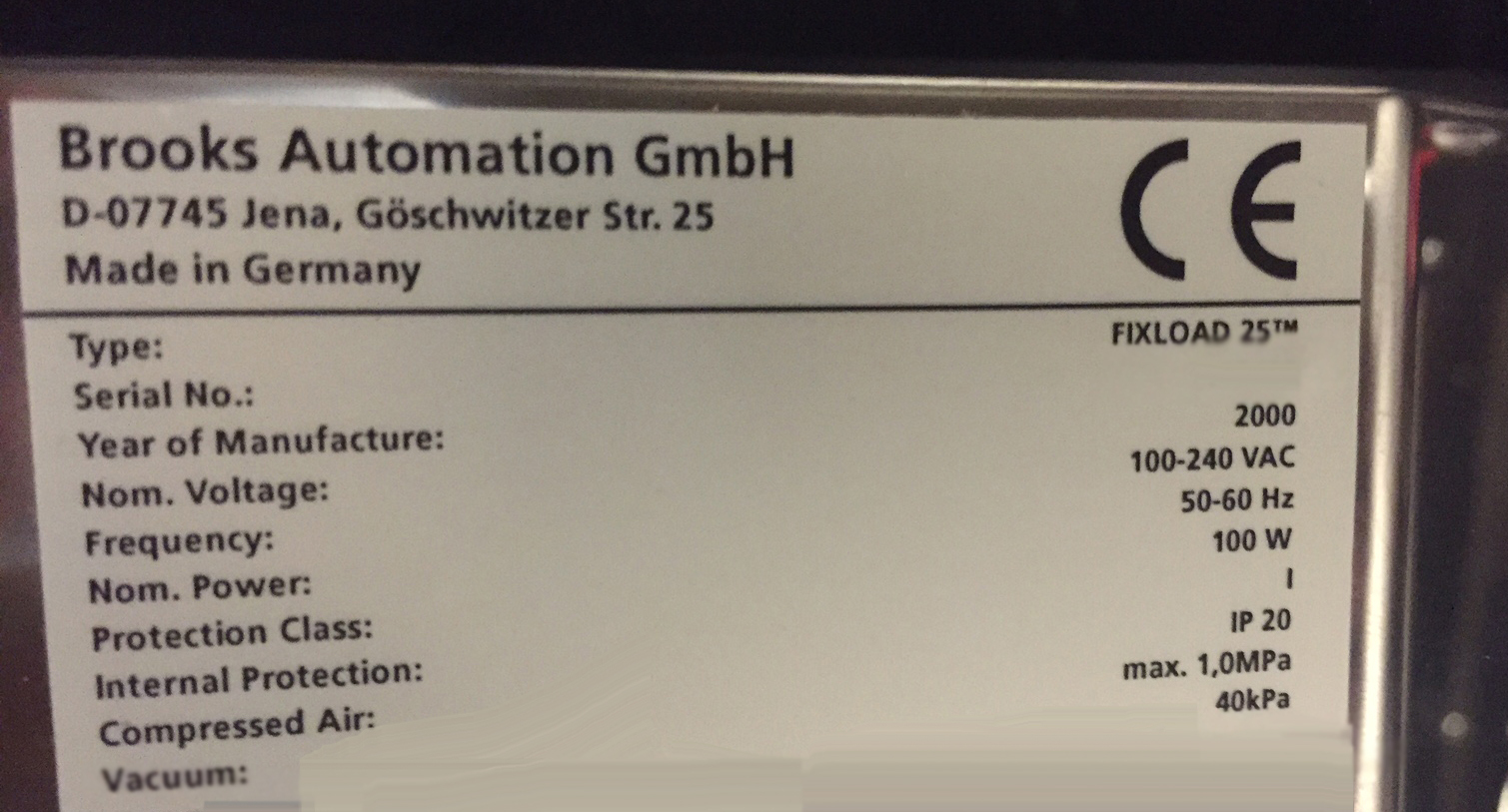

Used BROOKS AUTOMATION / JENOPTIK Fixload 25 #9159888 for sale

URL successfully copied!

Tap to zoom

BROOKS AUTOMATION / JENOPTIK Fixload 25 is an automated wafer handling equipment designed for the efficient loading and unloading of semiconductor wafers and cassettes. The system is capable of handling wafers up to 200mm in diameter, and can accommodate a variety of cassette sizes. The unit consists of a three-axis servo-driven robot, a base for the robot, a control-computer, an operating machine and a loading/unloading station. The robot is fitted with two linear motion stages and one rotational motion stage, allowing for precise wafer and cassette loading and unloading. These motion stages provide fast cycle times and reliable performance. The tool also features an infrared detector and bright LED light source. This allows for accurate identification of wafer positioning when loading and unloading cassettes. This also ensures that cassettes are loaded in the correct orientation without manual intervention. For efficient and accurate loading and unloading, JENOPTIK Fixload 25 uses several safety features including cushioned corners, automatic wafer-level sensors and a cassette-level sensor. This ensures that wafers enter the loading/unloading station securely, and that cassettes are loaded and unloaded correctly. The asset also features an advanced software suite, which is used to monitor model performance and coordinate automation tasks. This software also includes integrated safety functions for equipment protection against any errors during automation processes. BROOKS AUTOMATION Fixload 25 is an efficient and precise wafer handling system. Its robot and motion stages provide fast cycle times and reliable performance, while its safety features ensure secure loading and unloading. The integrated software and safety functions also allow for greater unit protection.

There are no reviews yet