Used BROOKS AUTOMATION / JENOPTIK Vision #293624682 for sale

URL successfully copied!

Tap to zoom

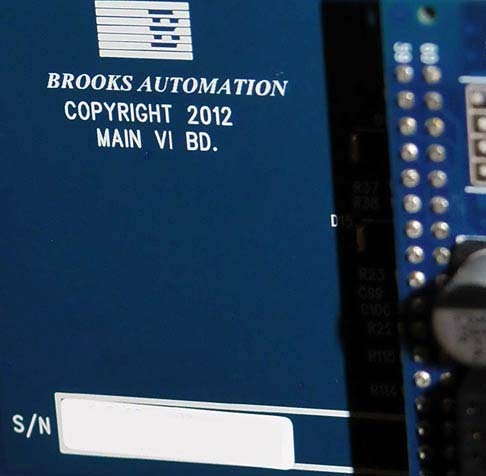

ID: 293624682

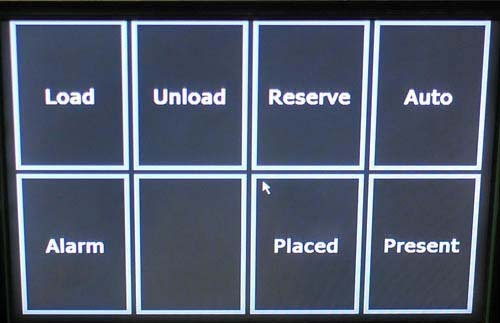

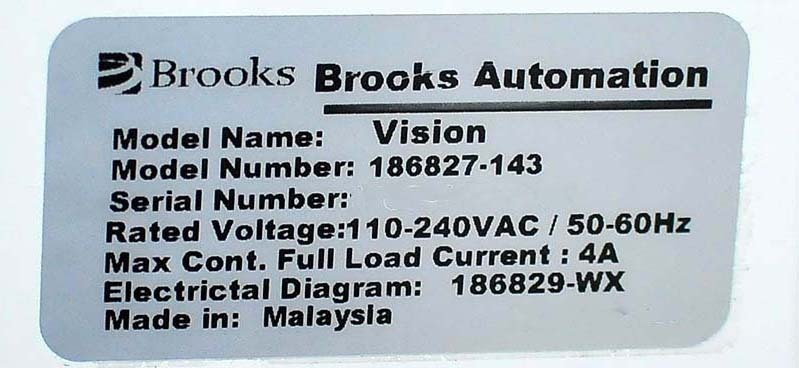

Load port

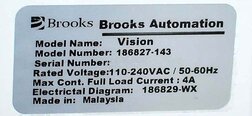

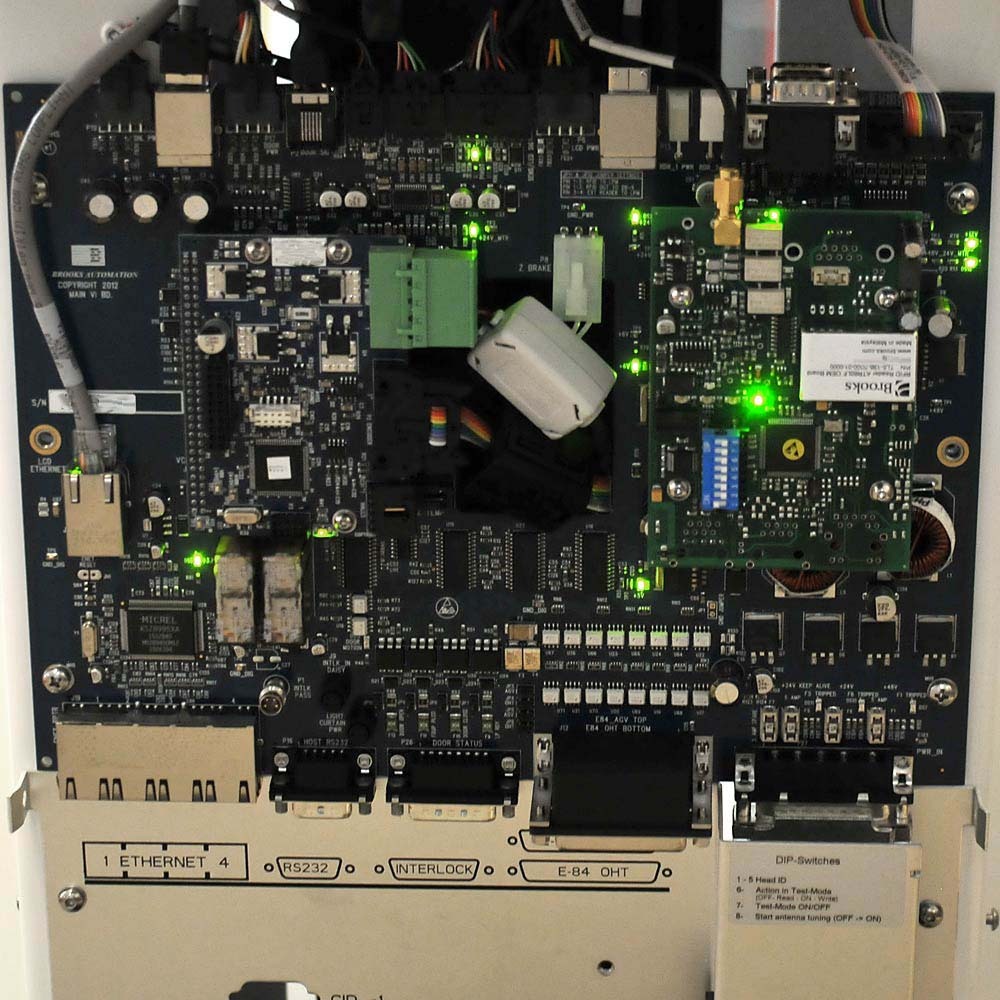

Model number: 186827-143

Part number:

180489-B02

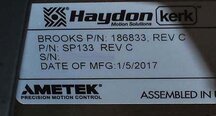

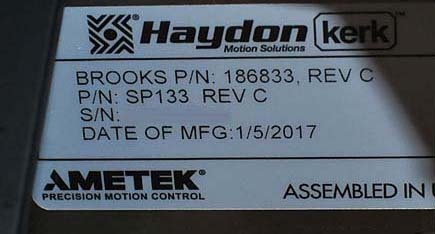

AMETEK SP133

BROOKS 186833

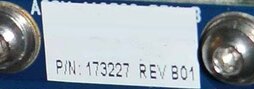

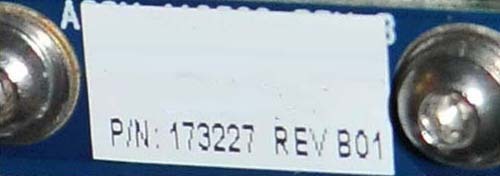

173227

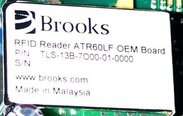

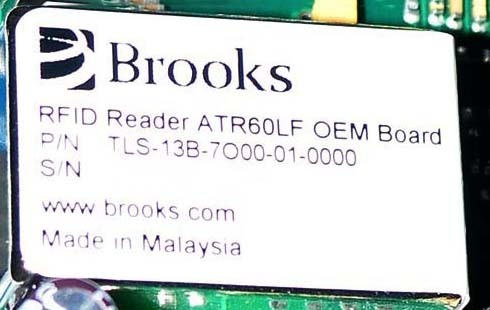

TLS-13B-7O00-01-0000 RFID Reader ATR60LF OEM board

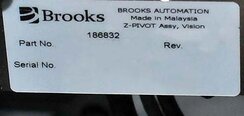

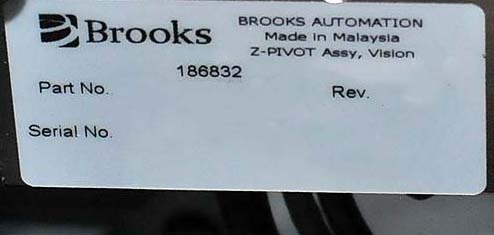

186832 Z-Pivot assy

Power supply: 110-240 V, 50-60 Hz, 4 A.

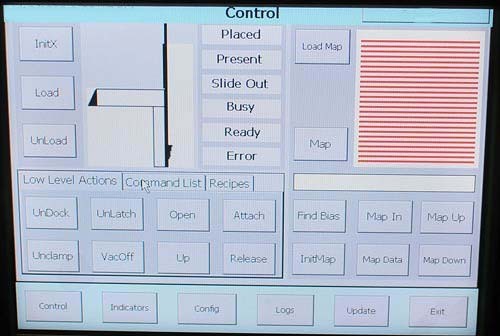

BROOKS AUTOMATION / JENOPTIK Vision is a wafer handler that is used for robotic automation in the semiconductor industry. It is a fully automated wafer handling solution, designed to eliminate manual handling of wafer fabrication processes. It is designed to provide a safe, efficient, and cost-effective solution for handling wafers. JENOPTIK Vision wafer handler is designed to provide high throughput and accuracy. It is equipped with multiple sensors and a BROOKS AUTOMATION Vision equipment that allow it to detect and measure defects in the wafers. Additionally, its Vision system can recognize the orientation of the wafers and automatically adjust the wafer handling direction. This allows the wafer handler to quickly switch between wafer types and reduce cycle time. The wafer handler utilizes a number of mechanisms to handle different types of wafers. For example, it uses a belt-feeder unit to feed wafers sequentially from the loader onto the deposition stages. Additionally, it features vacuum-based chucks and anti-static contact pads which are used to securely transfer wafers between stages. This prevents contamination and dislocation of the wafers. The wafer handler is also equipped with a micropositioner machine which provides precision and repeatability to critical stages such as photo lithography and etching. The micropositioner is also used for the alignment of multiple die on the same wafer which ensures accuracy during critical processes. In addition to these mechanisms, BROOKS AUTOMATION / JENOPTIK Vision wafer handler also comes with a user-friendly Linux operating tool which enables fast and simple programming. This allows the technician to quickly set up and adjust programs to maximize throughput and reduce costs. Lastly, the wafer handler is designed with multiple safety protocols. It is equipped with an emergency stop asset and the operating model is designed to prevent unsafe inputs. Additionally, all modules can be accessed and monitored remotely, allowing for the maximum flexibility and control of the equipment. Overall, JENOPTIK Vision wafer handler is an efficient and cost-effective solution for robotic automation in the semiconductor industry. By combining its accurately controlled mechanism, clever BROOKS AUTOMATION Vision system, user-friendly Linux operating unit, and safety protocols, the wafer handler provides a reliable and efficient tool for wafer fabrication processes.

There are no reviews yet