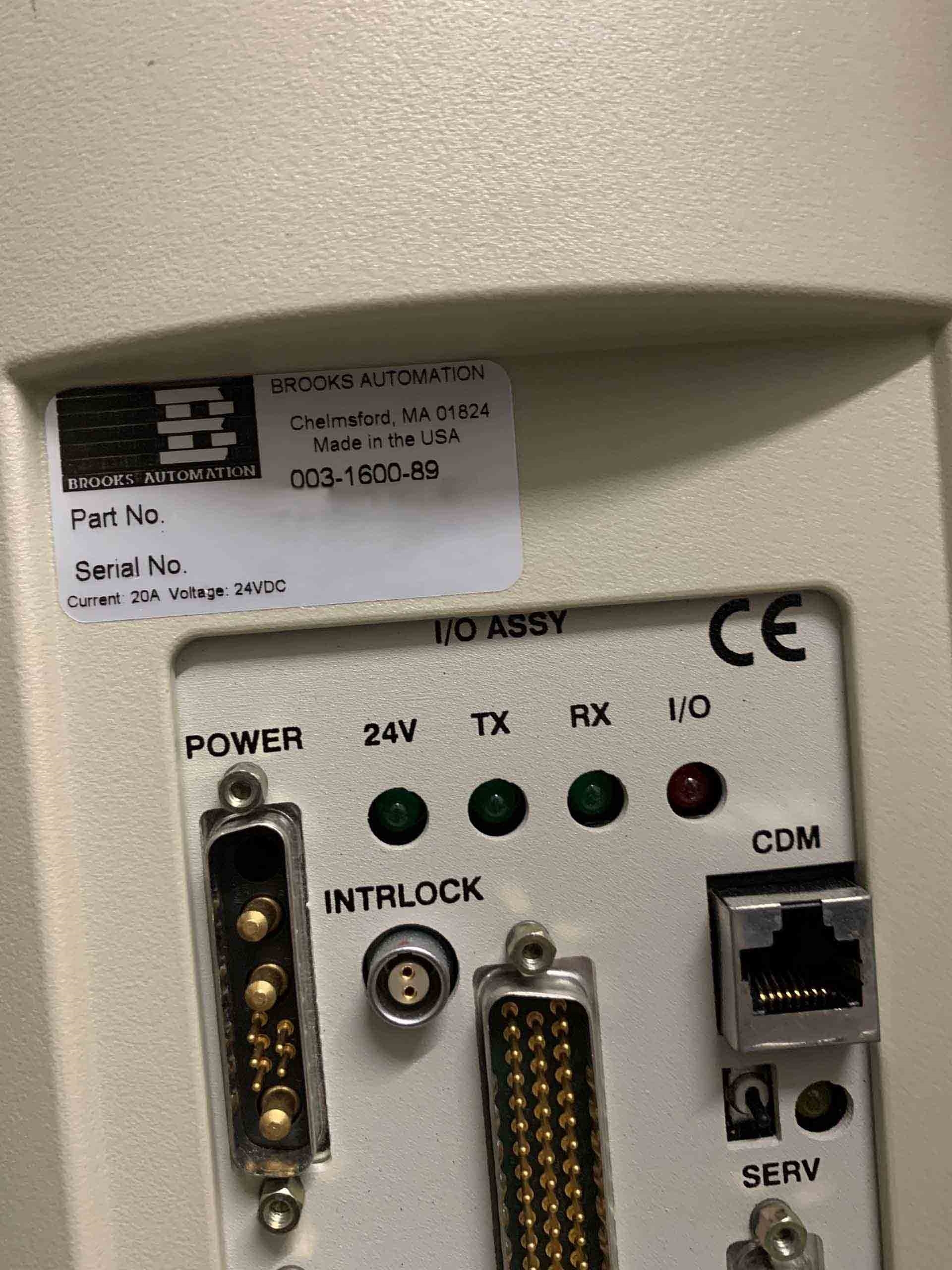

Used BROOKS AUTOMATİON Magnatran #9262078 for sale

URL successfully copied!

Tap to zoom

BROOKS AUTOMATİON Magnatran is a high performing wafer handler designed to fill the needs of the cleanroom automation market. Magnatran is capable of transferring wafers up to 13" (330mm) in diameter within a controlled environment. This wafer handler provides a safe and reliable means of wafer transfer from one point in the automated process to another. BROOKS AUTOMATİON Magnatran is designed to accommodate various sizes of wafers and multiple chip configurations. Its nesting ability allows for wafers to be organized in any pattern that facilitates efficient handling, and the ability to accommodate various sizes of wafers ensures a full range of production capabilities. The transfer mechanism employed is a linear drive motor, which provides accuracy and speed by utilizing a profile rail along with suitable actuators. By using servo motors, this wafer handler is able to move the wafers in a controlled and accurate manner. This wafer handler is also designed with several safety features, which guarantee that no damage will occur to wafers during transfer. The combination of servo motors and profile rail enable the motion of each wafer to remain in a set path, meaning that wafers are never crossed or wiped against each other. Furthermore, the solid-state components mean that the effect of noise and vibration on the wafers are minimized, and this wafer handler also has the capability to detect any obstruction and stop the motion of the wafer. The integrated controller system allows for great flexibility in defining the parameters of each transfer cycle, including the start position, direction and speed. The integrated network comprises of network interface cards, controller interface cards and universal serial BUS (USB) ports which enable easy digital connection to the host environment. Compared to other wafer handlers, Magnatran offers a low-cost, reliable and flexible solution for transferring wafers within a controlled cleanroom environment. It also provides fast and efficient transfer speeds, allowing production to progress quickly and efficiently. This wafer handler has been designed to meet the needs of the semiconductor industry, and to ensure the continued success of the automated production process.

There are no reviews yet