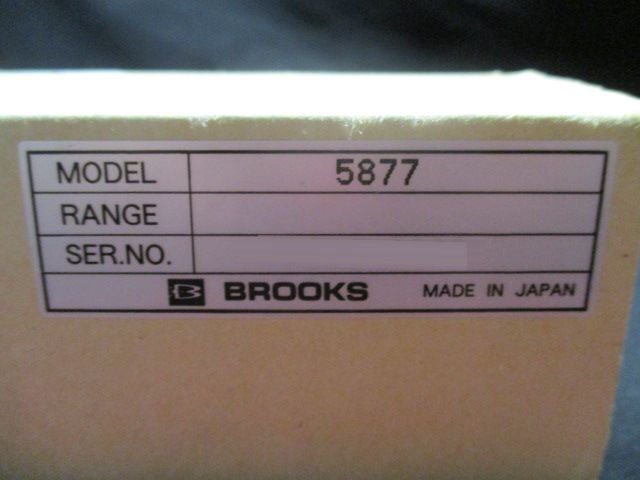

Used BROOKS / PRI AUTOMATION 5877 #9353204 for sale

URL successfully copied!

Tap to zoom

BROOKS / PRI AUTOMATION 5877 is an automated wafer handler designed to maximize throughput and performance in wafer processing applications. It features a unique single plane architecture which allows for the transfer of up to 21 wafers simultaneously. The equipment is fully automated with multiple stages of automated handling, loading, and unloading to ensure a continuous throughput of wafers. The automated wafer handler is equipped with many features including robotic arm controls, programmable linear motors, and a full-featured programmable logic control (PLC) system. The robotic arm controls allow for precise movement of the wafers with manual or automated adjustments. The programmable linear motors enable consistent and repeatable motion of the wafers while the PLC unit enables the exchange of operational data with other systems in the application. Also, this automated wafer handler includes several safety features such as over- and under-travel protection and a mechanical interlock machine. BROOKS 5877 also includes a wafer handling subsystem that is based on a conveyor tool. This subsystem consists of rollers and belts that transfer wafers from the loading station to the unloading station. The rollers move the wafers horizontally while the belts move them vertically. Moreover, the wafer handler subsystem also contains several motor-driven devices such as a disk drive, a sensing arm, and a counter. The disk drive lifts and lowers the wafers, the sensing arm reads and records wafer data, and the counter records the number of wafers that have been processed. Furthermore, the integrated vision asset enables precise tracking of wafers during loading and unloading. It also reduces setup time by supporting automatic setup of wafer size and spacing. Additionally, PRI AUTOMATION 5877 comes with a separate wafer heat treatment chamber that can be connected and controlled via the PLC. This chamber can be programmed to treat the wafers in various ways such as anneal, diffusion, etching, encapsulation, and wafer debonding. In summary, 5877 is an automated wafer handler specifically designed for wafer processing applications. It features an integrated vision model, a wafer handling subsystem, and a wafer heat treatment chamber that enable precise tracking and the treatment of wafers. It is also capable of handling up to 21 wafers simultaneously and is equipped with a wide range of safety features. Overall, this automated wafer handler provides a reliable and efficient solution for wafer processing applications.

There are no reviews yet