Used BROOKS / PRI AUTOMATION / EQUIPE ATM 407-1-S #9195685 for sale

URL successfully copied!

Tap to zoom

ID: 9195685

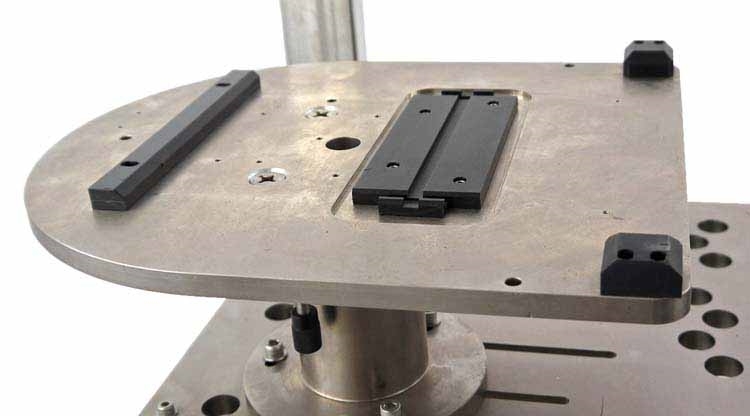

Atmospheric wafer handling robot

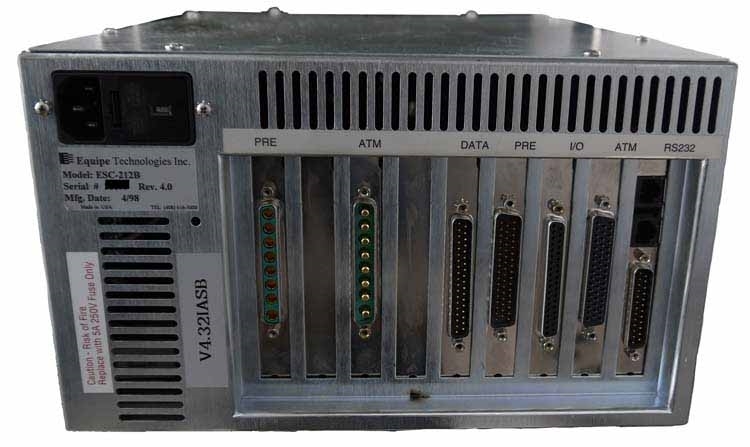

Controller: ESC - 212B

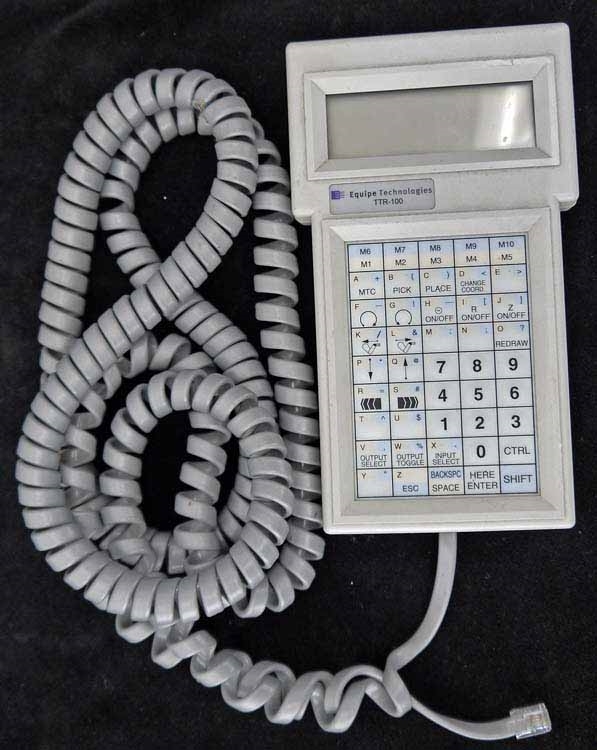

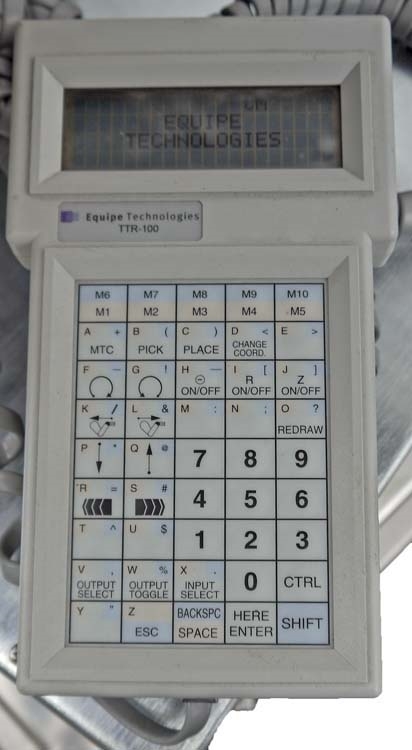

Teach pendant: TTR - 100

Cables:

EQUIPE 2002 - 0011 - 07PCE

EQUIPE 2002 - 0011 - 07SC

EQUIPE 2002 - 0031 - 07SCE

EQUIPE 2002 - 0012 - 07SCE

EQUIPE 2002 - 0012 - 07PCE

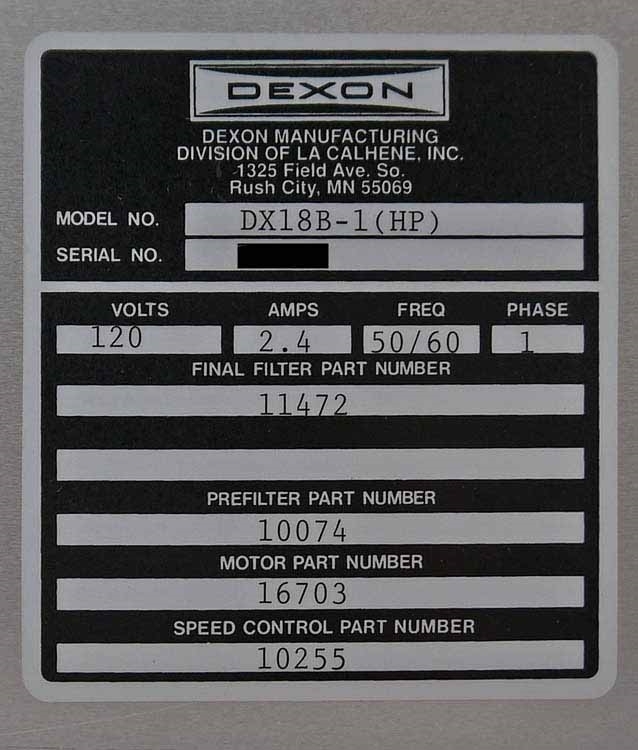

(2) DEXON DX18B - 1 (HP) Filter / Speed controllers

Not included:

Power cord

panel covers

Accessories.

BROOKS / PRI AUTOMATION / EQUIPE ATM 407-1-S wafer handler is a highly advanced robotic automation system designed to move, manipulate, and inspect semiconductor wafers. It is used in precision manufacturing processes in cleanroom environments. BROOKS/PRI handler is a modular system that can be customized for individual process needs. It comprises a mainboard, multiple transportable wafer cassettes, a wafer shuttle, and an inspection and detection station. The mainframe consists of a base frame, an operator interface, a power supply, pneumatically operated motion components, and servo motor drives. The transportsable wafer cassettes provide an automated means of transporting the wafers from one process station to another. They allow for quick, accurate, and repeatable loading and unloading of wafers into the mainframe. They also come equipped with a barcode reader for improved data integrity. The wafer shuttle allows for wafers to be transported from one process station to another within the mainframe. The shuttle is pneumatically driven and can be custom-configured for any number of wafers. It is designed for high accuracy and repeatability with minimal vibration, ensuring high-quality wafer handling. The inspection and detection station is used to detect and measure any defects of the wafers. It is equipped with advanced imaging and light sensors that allow for the accurate measurement of the wafers. The sensors can accurately detect wafer defects and determine any irregularities or contamination. BROOKS ATM 407-1-S wafer handler is a highly advanced, customisable robotic automation system designed to provide high-precision wafer handling and inspection that is capable of meeting the most demanding production needs in today's modern cleanroom environments. With its modular construction, versatile applications, and robust construction, it is an ideal automation solution for the most challenging semiconductor manufacturing processes.

There are no reviews yet