Used BROOKS / PRI AUTOMATION MTR 5 #178989 for sale

URL successfully copied!

Tap to zoom

ID: 178989

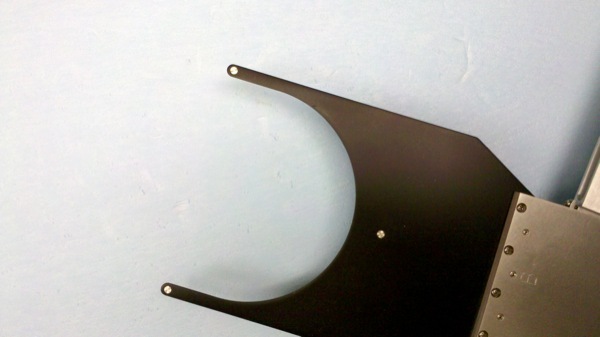

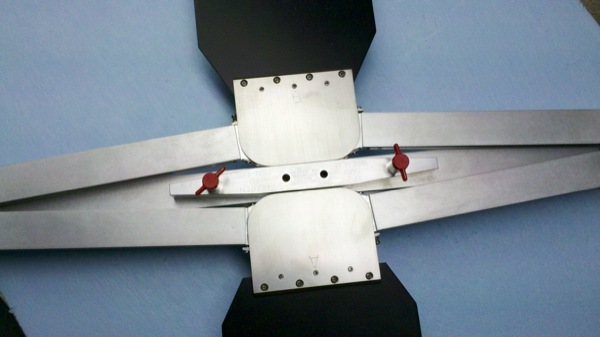

Vacuum robot and arm set

Arm set configured with 8" wafer end-effectors

(1) end-effector: Kalrez pads, stainess steel pads for >300C hot wafer handling.

BROOKS / PRI AUTOMATION MTR 5 is a high-speed, high-precision wafer handler designed to coordinate wafer loading, testing, and shipping operations. It features an intuitive operator interface, robust servo-controlled movements, and a host of other features. BROOKS MTR 5 employs a fully automated die picking equipment for fast and accurate wafer handling, capable of reaching speeds of up to 100 pieces per minute. This system is highly accurate, allowing tight tolerances of 0.3mm +/-. The picker movement is servo-controlled, using two independently positionable high-precision cross-rollers and a central support plate. This arrangement offers a high degree of flexibility and precision, as well as greater stability when handling wafers. PRI AUTOMATION MTR5 includes numerous automatic functions for controlling and monitoring the loading, testing, and shipping of wafers. These include sensor-controlled die sorting, adaptive die placement, dual-position alignment, selective die initialization, and automatic feeding. Each operation is monitored by Allen Bradley controls equipped with a PC-based operating unit and an EtherNet/IP diagnostic module. This allows for real-time performance feedback and quick fault detection. MTR5 is designed to be robust and reliable. Its components are engineered for maximum up-time and require minimal maintenance. The entire machine is built on a robust, powder-coated, extruded aluminum frame that not only eliminates the need for grounding, but also provides increased stability and support. The belt drive tool is built with high-grade steel that is thermally treated to up to 1200°F for enhanced durability and reliability. In addition, BROOKS / PRI AUTOMATION MTR5 is equipped with a powerful and efficient air asset for both handling and drive functions. This efficient and quiet air model further reduces maintenance costs, making BROOKS MTR5 highly cost-effective. Finally, the equipment is equipped with an advanced safety interlock that prevents accidental contact with the die handlers, protecting both the operators and the product. PRI AUTOMATION MTR 5 is an all-in-one wafer handling system that offers speed, precision, safety, and reliability. Its computerized controls, intuitive user interface, and advanced safety features make it an ideal choice for any wafer loading, testing, or shipping operation.

There are no reviews yet