Used BROOKS / PRI AUTOMATION P/N 002-7391-08 #128190 for sale

URL successfully copied!

Tap to zoom

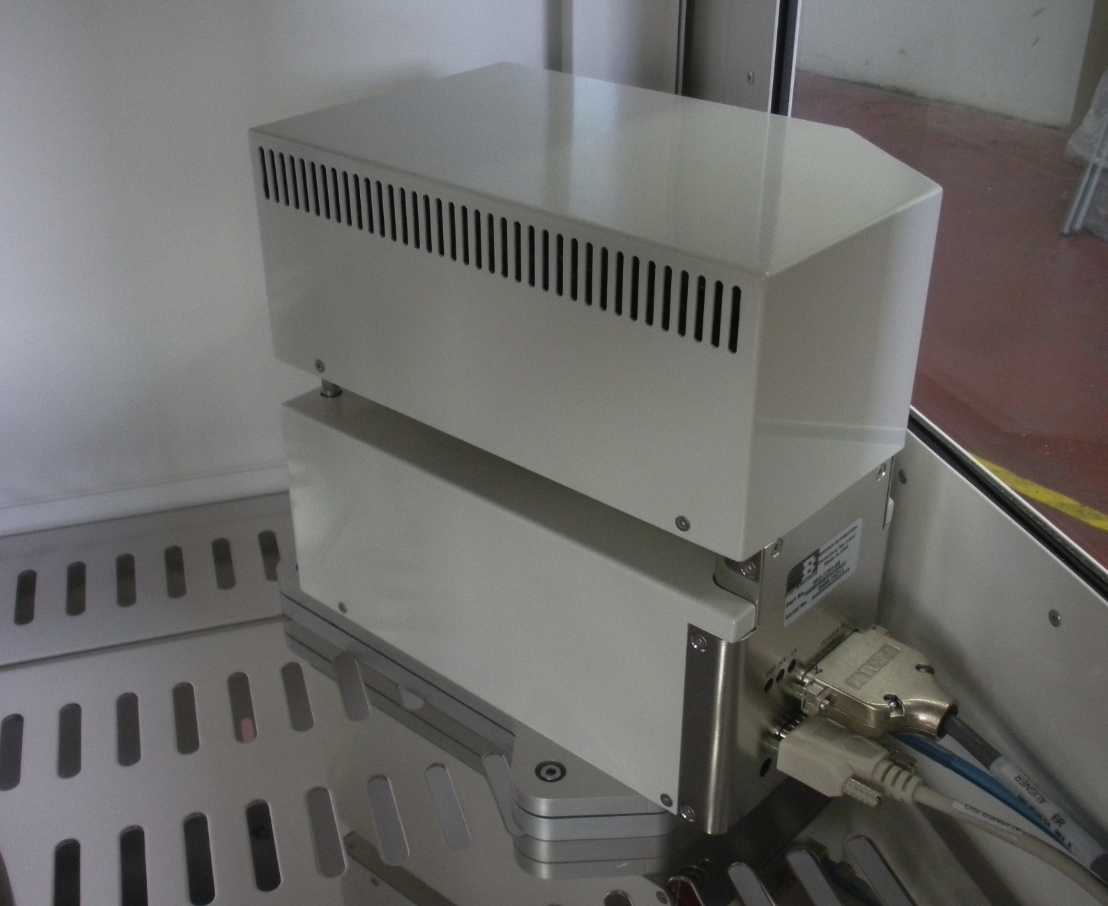

BROOKS P/N 002-7391-08 is a leading-edge wafer handler designed for use in semiconductor fabrication plants. The automation equipment has a flexible design allowing for highly efficient, versatile wafer moving capabilities, all in a compact, space-saving form factor. It is capable of handling wafer sizes from 150mm to 200mm diameter, and offers a full range of automation for vacuum wafer handling, including wafer aligning, lifting, transferring, and stacking. PRI AUTOMATION P/N 002-7391-08 features a powerful multi-axis motion control system with high torque, brushless servo motors. This ensures precise, smooth, and consistent robot movements, even with heavy payloads. The integrated motion controller features a user-friendly graphical interface, and programming is easily accomplished through a library of commands. The wafer handler includes a patented vision unit for precision wafer inspection and alignment. An intuitive software interface enables easy vision machine configuration and programming. The vision tool can perform various three-dimensional measurements on the entire wafer, making it possible to inspect for surface defects and other anomalies. BROOKS / PRI AUTOMATION P/N 002-7391-08 is easy to set up and is quite reliable. Key components are made from corrosion-resistant stainless steel. The wafer handler is designed to protect wafers from jostling, vibration, and other sources of damage during transport. Furthermore, the asset is highly accurate and incorporates many safety features, such as over-torque protection and tooling collision detection. Overall, BROOKS P/N 002-7391-08 is an affordable and reliable wafer handling model designed to optimize throughput and reduce time-consuming manual wafer handling operations in semiconductor fabrication plants. It offers precise motion control and an integrated vision equipment for precise wafer alignment and inspection. The system is easy to set up, and efficient and reliable, making it a great choice for high-volume production environments.

There are no reviews yet