Used CYBEQ 6100 #9091665 for sale

URL successfully copied!

Tap to zoom

ID: 9091665

Dual arm robot

Robot: PER8000

Robot Model: 0125-0605

Controller: 6100

CYBEQ teach pendant

Integrated CPU

Internal adjustable vacuum detection switches

End effectors with tape O-rings and mounting screws

Hama laser / scanner

Dual end-effectors

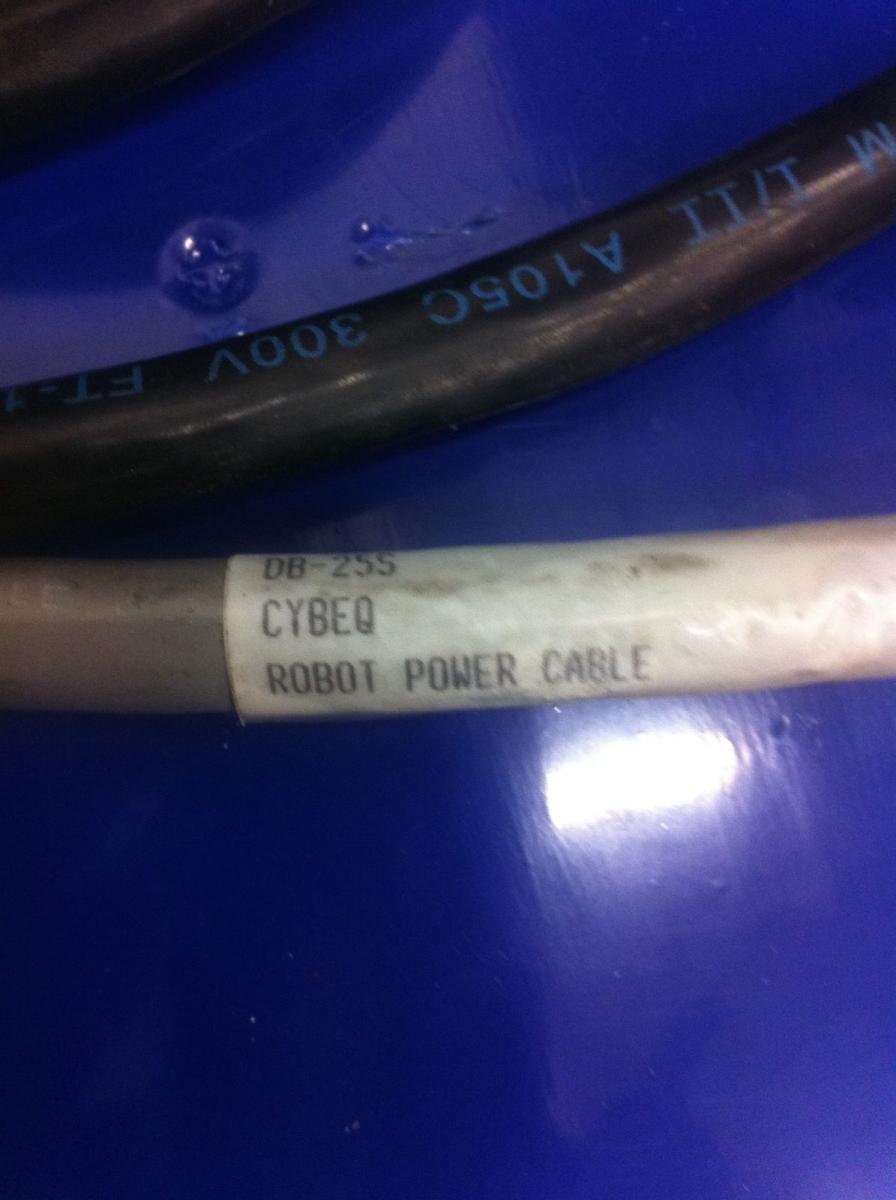

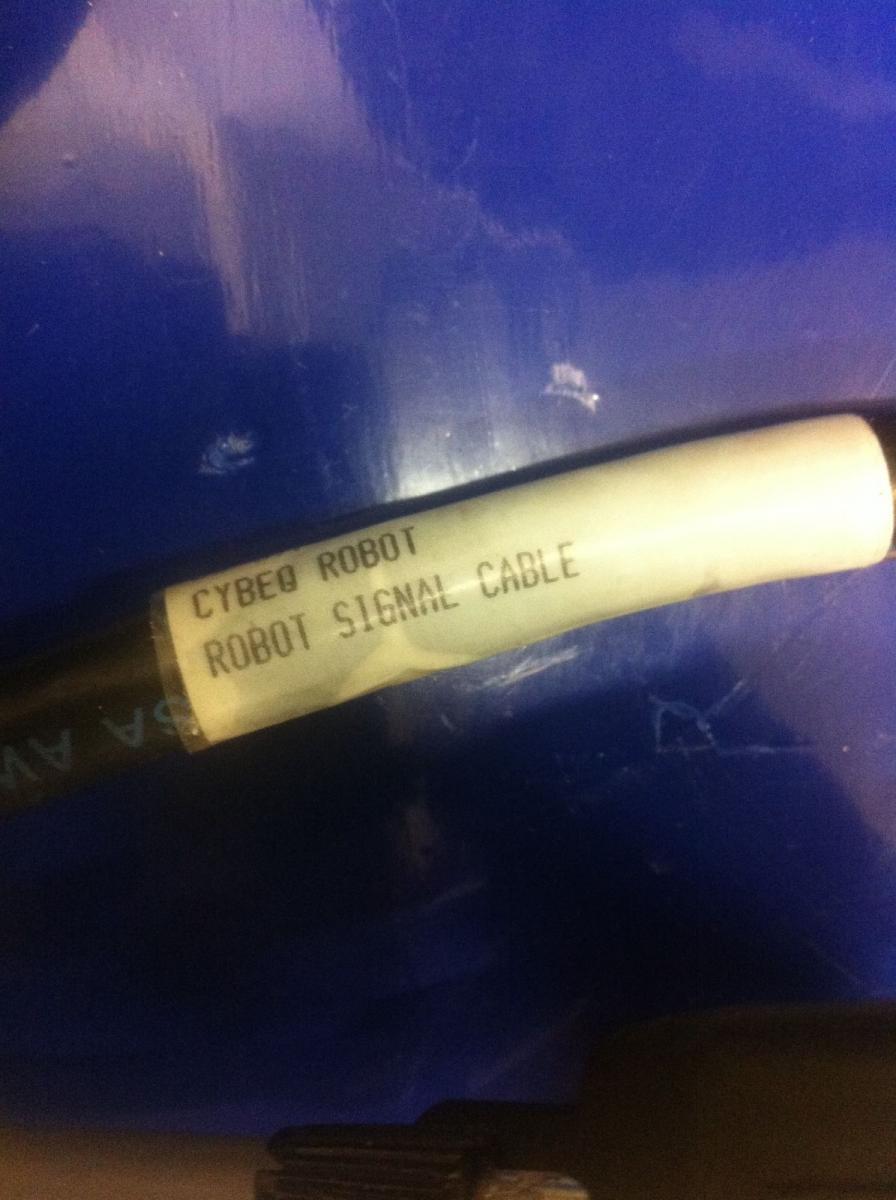

Power and signal cables

Cables

Option:

Dual vacuum Tee-off connections

Power: 220/240VAC or 110/120VAC.

CYBEQ 6100 wafer handler is a high-precision, automated wafer-setting solution designed to maximize efficiency and improve the accuracy and throughput of the wafer handling process. This advanced wafer handler equipment is designed to facilitate both manual and automated loading of wafers into a production environment with minimal downtime and error-free operation. The system is equipped with a precision motion controller and feedback devices that rapidly adjust the wafer-handling speed and coordinates in response to predefined settings. The motion controller also provides real-time feedback for error diagnosis and optimization of the motion profile. 6100 can accommodate wafer sizes ranging from 75mm to 200mm in diameter, and can handle a variety of wafer diameters within these limits. The unit also supports axial and radial accuracy, as well as pitch, roll and yaw compensation, to ensure that the wafers are set precisely and accurately into place. The handheld configuration of the wafer handler is both intuitive and ergonomic, helping to minimize operator fatigue. It is also equipped with an intuitive graphical user interface and built-in diagnostics that make maintenance and troubleshooting of the machine easy and efficient. Additionally, CYBEQ 6100 wafer handler features maximum safety and tool-dependent locking of all components to prevent accidental opening and contamination of wafer surfaces. This is enabled by security functions such as a code lock, emergency stop and safety interlock that are built into the asset. Overall, 6100 is the ideal solution for high-precision, automated wafer-setting and handling processes. It creates efficient and error-free operations with minimal downtime, while ensuring maximum safety and accuracy of the whole model.

There are no reviews yet