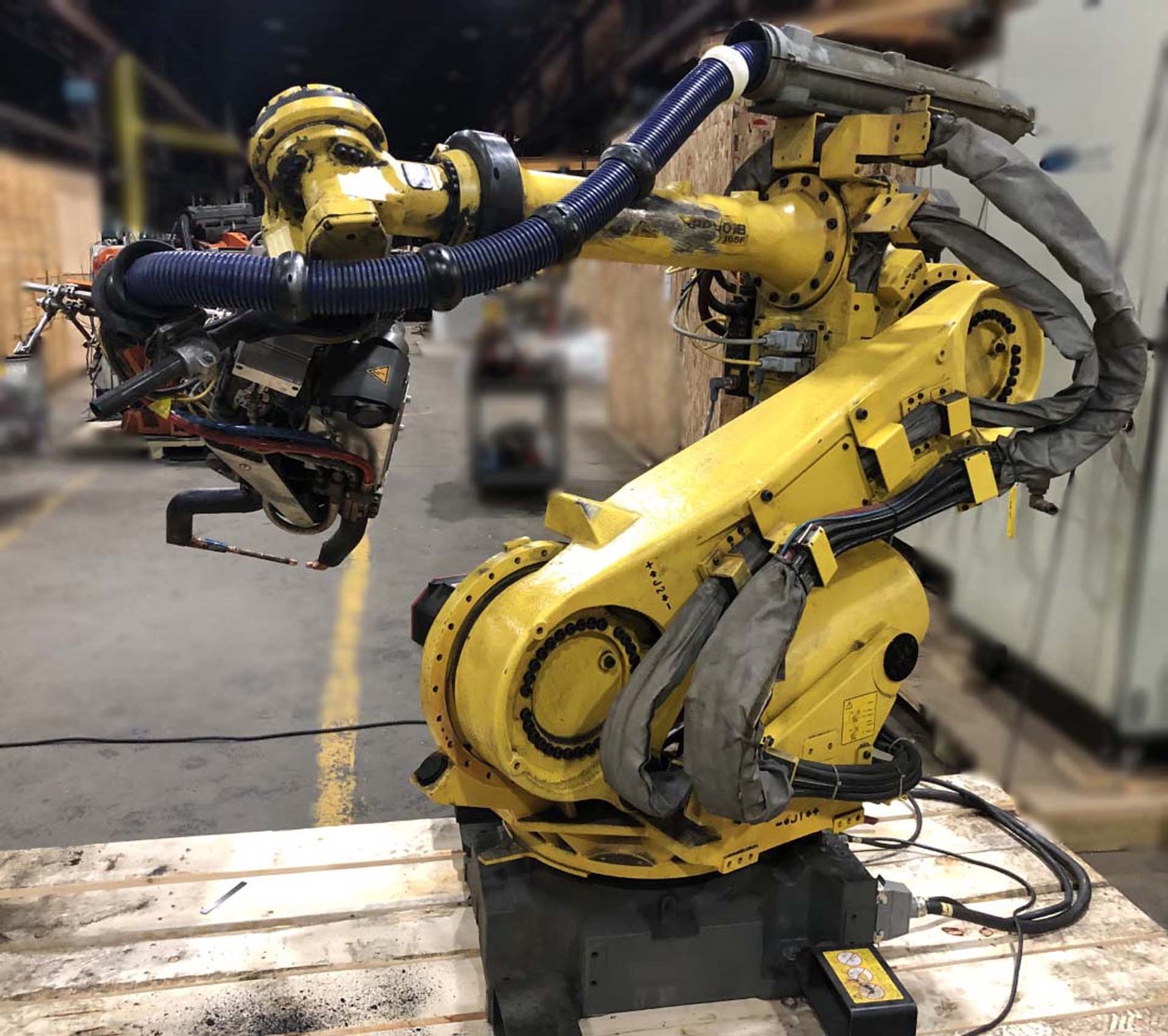

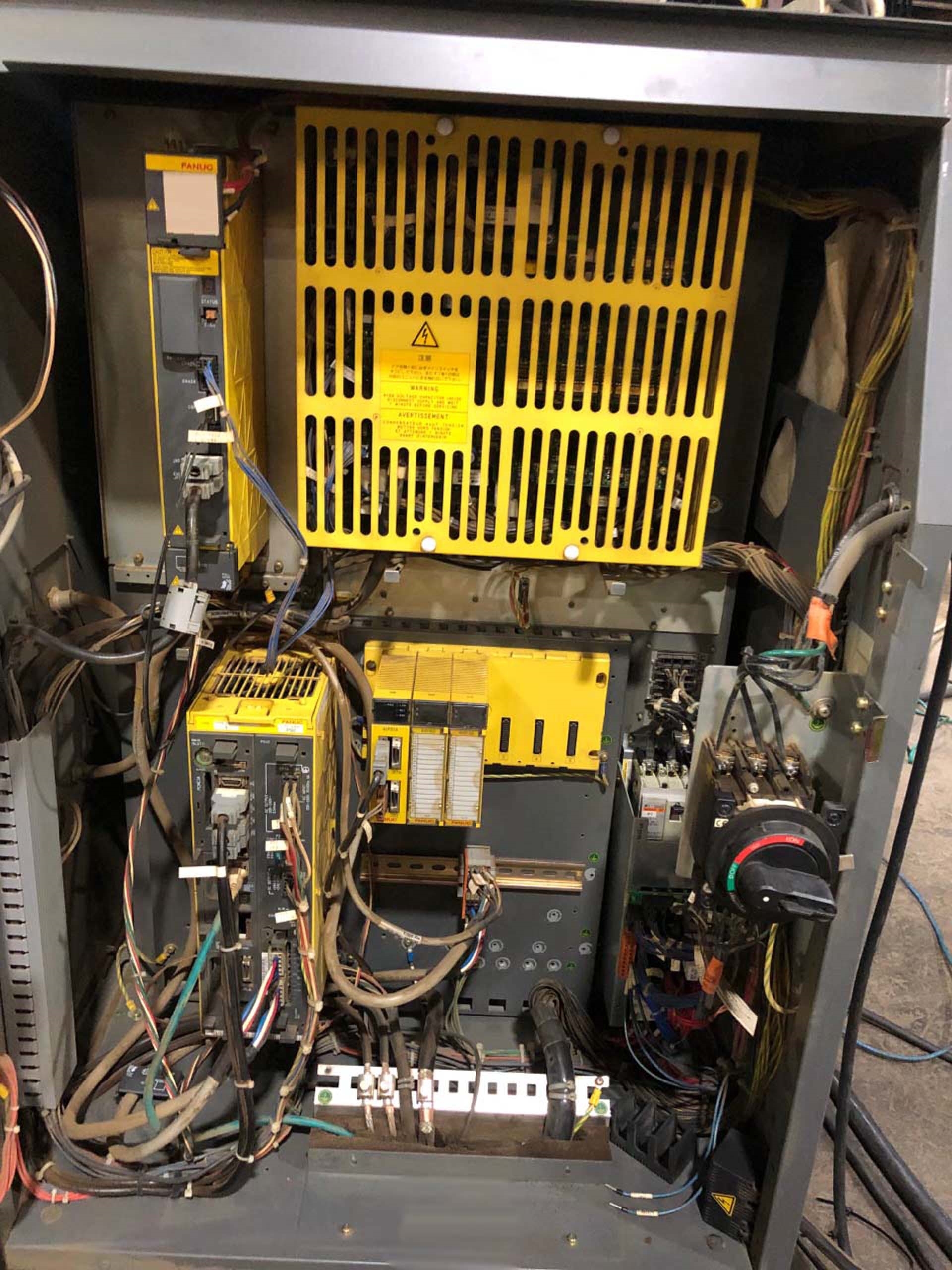

Used FANUC R-2000 IB #9251417 for sale

URL successfully copied!

Tap to zoom

FANUC R-2000 IB is a robotic wafer handling equipment designed for high-speed and precision wafer handling in the semiconductor industry. It is equipped with a 6-axis robotic arm and is capable of achieving highly precise wafer handling operations through its advanced motion control and vision systems. FANUC R2000IB is capable of handling up to 200 wafers per hour, reaching speeds of 80 mm/sec. The highly accurate 6-axis robotic end-effector offers flexible and accurate positioning of wafers for a variety of handling operations, including pick-and-place movement and sorting. This allows the system to handle wafers with a wide range of sizes, shapes, and materials, from small die sizes up to 200mm wafers. The vision unit is R-2000 IB's main tool for automated operations and can be configured to recognize individual die or wafer faces using a high-resolution camera machine. This visual feedback helps to minimize misalignments between the robot and the wafer, ensuring accurate and repeatable handling results with minimum human intervention. The management of the tool is also made simple by the various software applications available - either from FANUC or from third party suppliers. This allows users to customize the operation of the robot, create desakable programs for wafer handling, and track and record all operational data, including the number of passes, vibration, and other operating parameters. R2000IB is an extremely reliable asset thanks to its extensive safety features and built-in fail-safes. This includes a force-sensing model, redundant actuators, and a high-speed detection loop for detecting and correcting unexpected events. This ensures a safe and worry-free work environment, and allows for flexible and accurate wafer handling with minimal disruption during production.

There are no reviews yet