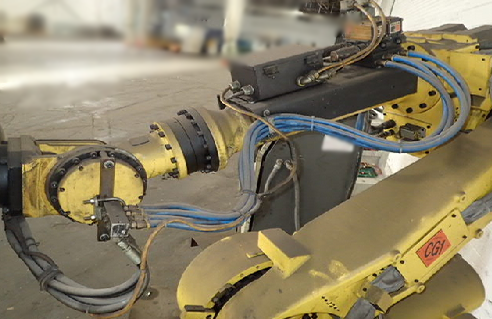

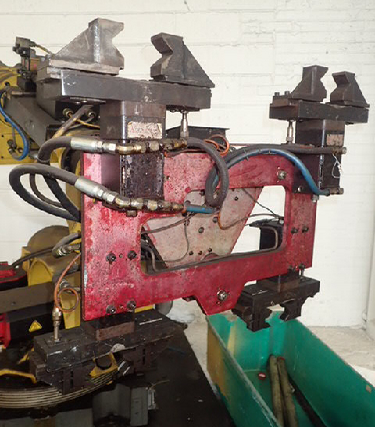

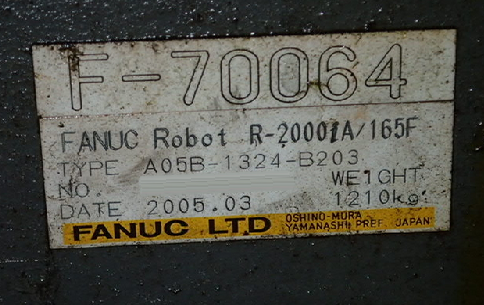

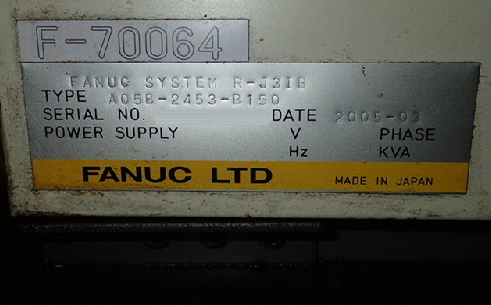

Used FANUC R2000iA 165F #9093576 for sale

URL successfully copied!

Tap to zoom

FANUC R2000iA 165F is a high-speed and highly accurate robot wafer handler used in semiconductor manufacturing processes. It is designed to rapidly transfer and process 300mm diameter wafers in semiconductor fabrication facilities. This robot uses the latest technology in robotic motion control and incorporates advanced safety hardware thatmonitor the safety perimeter during operation. The robot is designed to simultaneously maneuver and process wafers, allowing a much faster production cycle. The robot's payload capacity handles up to 165 wafers of varying sizes. The robot is also equipped with a wafer scanning system which helps it to accurately position each wafer within the production line. FANUC R-2000IA / 165F features six axes of articulated movement that allow for full three-dimensional operation. Its wrist joints are capable of entering narrow spaces for intricate handling, and its arm has a reach of 1800mm. The robot's real-time interactive capabilities enable it to coordinate and adjust to changes quickly in the production line. This allows for rapid cycle times and increased throughput. The robot is powered by a RISC processor, allowing for a high-speed compute and control platform. This helps to reduce cycle time by quickly processing and executing robotic instruction set commands. In terms of operation, the robot is optimized to achieve fast acceleration and deceleration, which helps to increase production speed and improves production cycle time. The robot is built with a modular design, which makes it easy to install and configure. This allows operators to quickly get the robot up and running with minimal setup time. In addition, the robot supports data-driven automation, which helps to reduce setup time by allowing it to learn operations from datasets. Safety is also a key feature of R-2000 IA / 165F. The robot is equipped with safety hardware that monitors the safety perimeter during operation.The robot also includes an emergency stop switch for immediate shutdown if an unforeseen event occurs. Overall, R2000iA 165F is an advanced robotic wafer handling system that can significantly speed up production cycles and improve accuracy and safety in semiconductor fabrication. The robot has a modular design and supports advanced features such as data-driven automation, enabling it to quickly adjust to changes in the production line.

There are no reviews yet