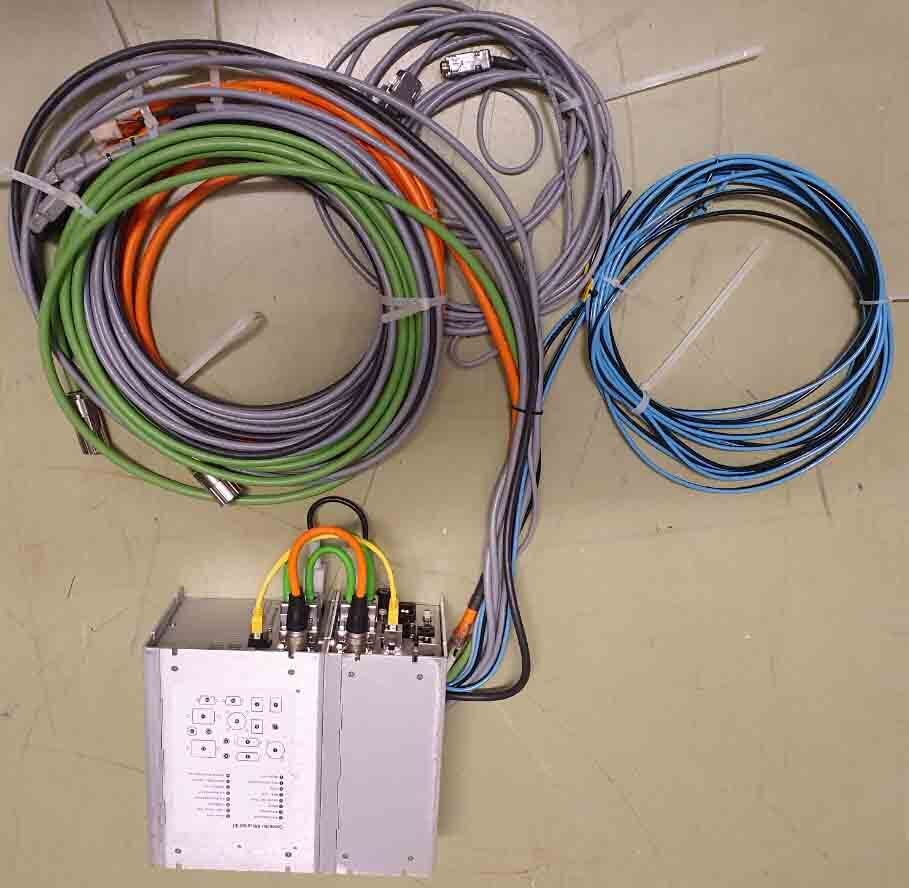

Used ISEL ROBOTIK IWH-BA13S24HDF-3 #293602549 for sale

URL successfully copied!

Tap to zoom

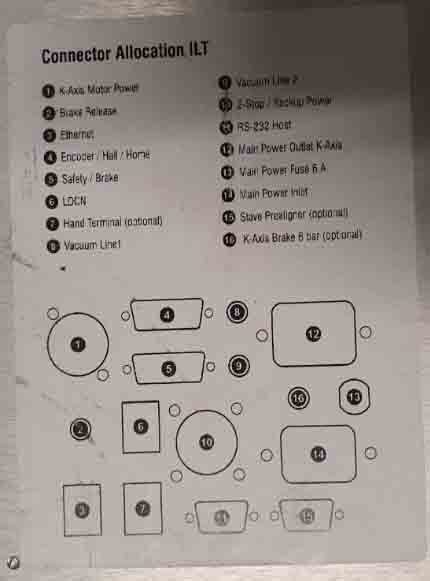

ISEL ROBOTIK IWH-BA13S24HDF-3 Wafer Handler is an automated device designed for the efficient handling, loading and unloading of individual wafers in the semiconductor industry. It is capable of achieving high accuracy and repeatability in its operations with an automated wafer handling equipment. IWH-BA13S24HDF-3 has a carriage frame made up of two axes - X-axis and a Z-axis, governed by two brushless DC-servo motors, providing high speed operation and precise positioning. Its X-axis movement is controlled by a single DC-servo motor with a resolver and offers a wide range of motion in various acceleration and deceleration profiles. The motor is controlled by ISEL ROBOTIK ULTRAROB controller, which is capable of implementing multi-axis operations. The Z-axis movement is governed by another DC-servo motor, used for the vertical movement of wafers. It also features an optical positioning system to adjust the wafer positions in both X and Z axes. The Z-axis is capable of lifting up to 2000N (=200kg) of weight, making it well suited for heavier components. ISEL ROBOTIK IWH-BA13S24HDF-3 Wafer Handler also has a wafer measuring and alignment unit, allowing for precise loading and unloading of individual wafers. The alignment and measuring machine is a combination of a CCD camera and light source that produces a bright light in order to measure the location and orientation of the wafers. In addition to the loading and unloading functions, IWH-BA13S24HDF-3 Wafer Handler is also able to perform pin inspections. It uses a pneumatic probe, which measures the height and dimensions of the components that are loaded on it, as well as the slots in the wafer holder. This method allows for the quick, accurate measurement of the wafers, helping to ensure the quality of the processes. In addition, ISEL ROBOTIK IWH-BA13S24HDF-3 has a vacuum tool that helps to grip and secure the individual wafers while they are being handled and loaded. In addition, the vacuum asset is designed to withstand any potential contamination from process chemicals and dust, ensuring the safety of the components. IWH-BA13S24HDF-3 is a highly efficient, time-saving wafer handling device with a large capacity for handling large amounts of wafers. It is capable of automating a range of production processes, such as loading and unloading wafers, pin inspection and wafer measurement, ensuring precise, repeatable processes with a high degree of accuracy. The device is also capable of being implemented in a variety of production environments, providing an efficient solution for increasing productivity and cost efficiency.

There are no reviews yet