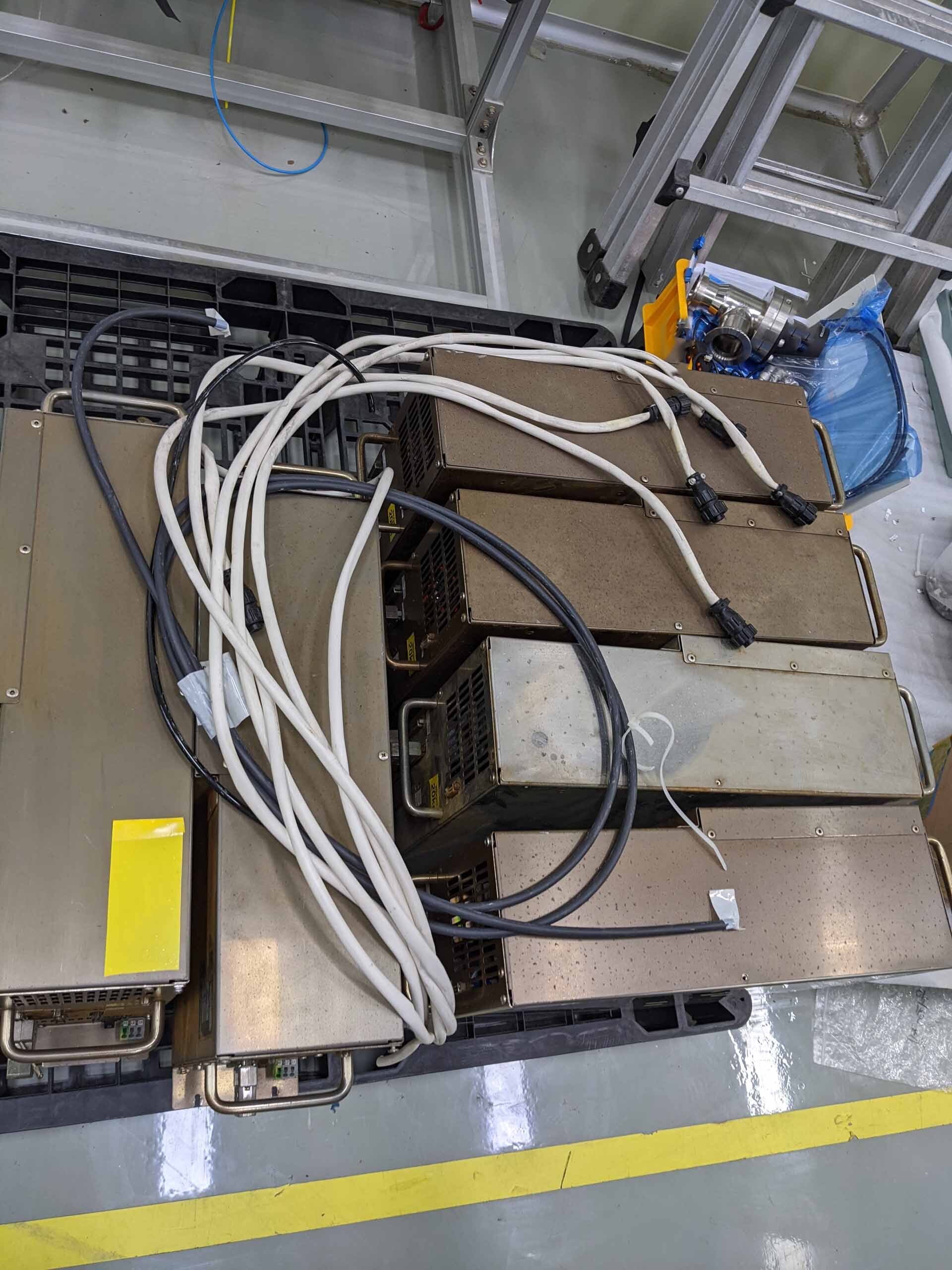

Used KAWASAKI 30C63E-A003 #293643260 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

KAWASAKI 30C63E-A003 is a Wafer Handler designed for high-precision and reliable performance. It is specifically designed for use in the semiconductor industry. 30C63E-A003 features a dual robot arm design, which is able to move wafer cassettes into and out of a main processing chamber. The robot arms can detect and grab the correct cassette, eliminating human errors and providing increased accuracy and reliability. KAWASAKI 30C63E-A003 is equipped with a reliable vacuum wafer suction equipment, which helps to ensure that wafers do not become damaged through improper handling. This wafer suction system is also independent of the robot arms, which allows the user to perform individual wafer manipulation without using the robot arms. 30C63E-A003 incorporates an advanced graphite sheet conveyor unit, which serves as a non-slipping layer between the wafer and the robot arms. The graphite sheet also reduces damage to the wafers. The conveyor machine is strategically placed in the passage space between the wafer cassette loader and the gate valve, allowing several wafers to be handled at once. KAWASAKI 30C63E-A003 is designed to provide easy accessibility and operation. The robot arms can be adjusted to the desired position for accurate pickup and placement, and this can be quickly adjusted with a simple rotation of the arm. Additionally, the robot arms can be moved left and right, as well as up and down. And the unit can be attached to a flat surface for greater stability. The front-end of 30C63E-A003 has a manual gate valve for controlling entry into the main chamber, providing quick and easy access for inserting and removing wafers. This gate valve is operated via a mechanical drive unit and electronic controller. Additionally, the gate valve is equipped with a temperature-measuring device to ensure a safe operating temperature. KAWASAKI 30C63E-A003 also includes an efficient cooling tool to manage the heat generated when processing wafers. The cooling asset circulates air through the wafer chamber to prevent internal components from becoming overheated, and it also prevents any condensation buildup inside the enclosure. 30C63E-A003 is a reliable, high-precision wafer handler designed to automate the difficult and time-consuming task of handling wafers within the semiconductor industry. The unit features a dual robot arm design; a reliable vacuum wafer suction model; a graphite sheet conveyor equipment; and an easy-to-operate gate valve. In addition, KAWASAKI 30C63E-A003 features a cooling system for managing heat generated when processing wafers.

There are no reviews yet