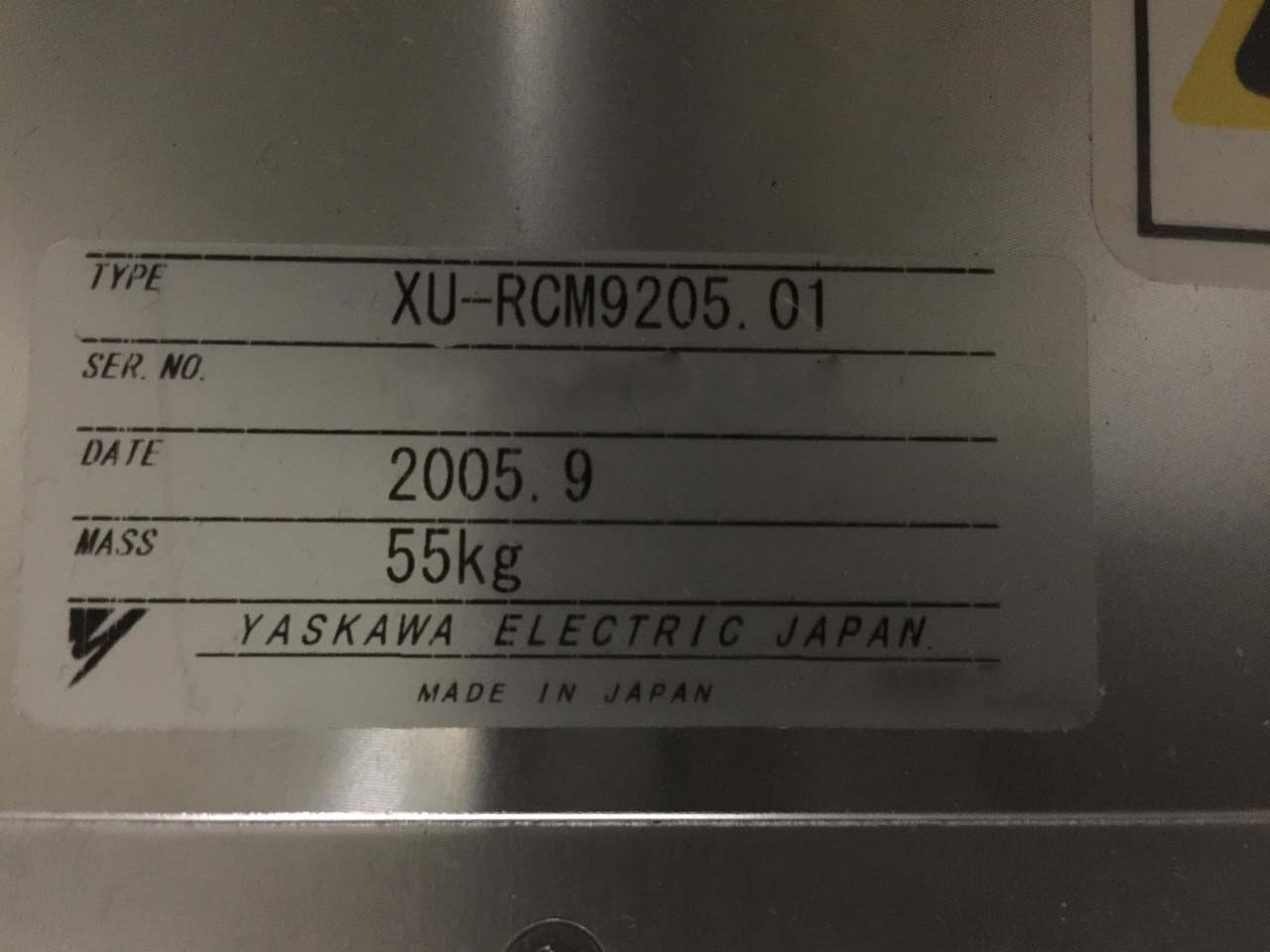

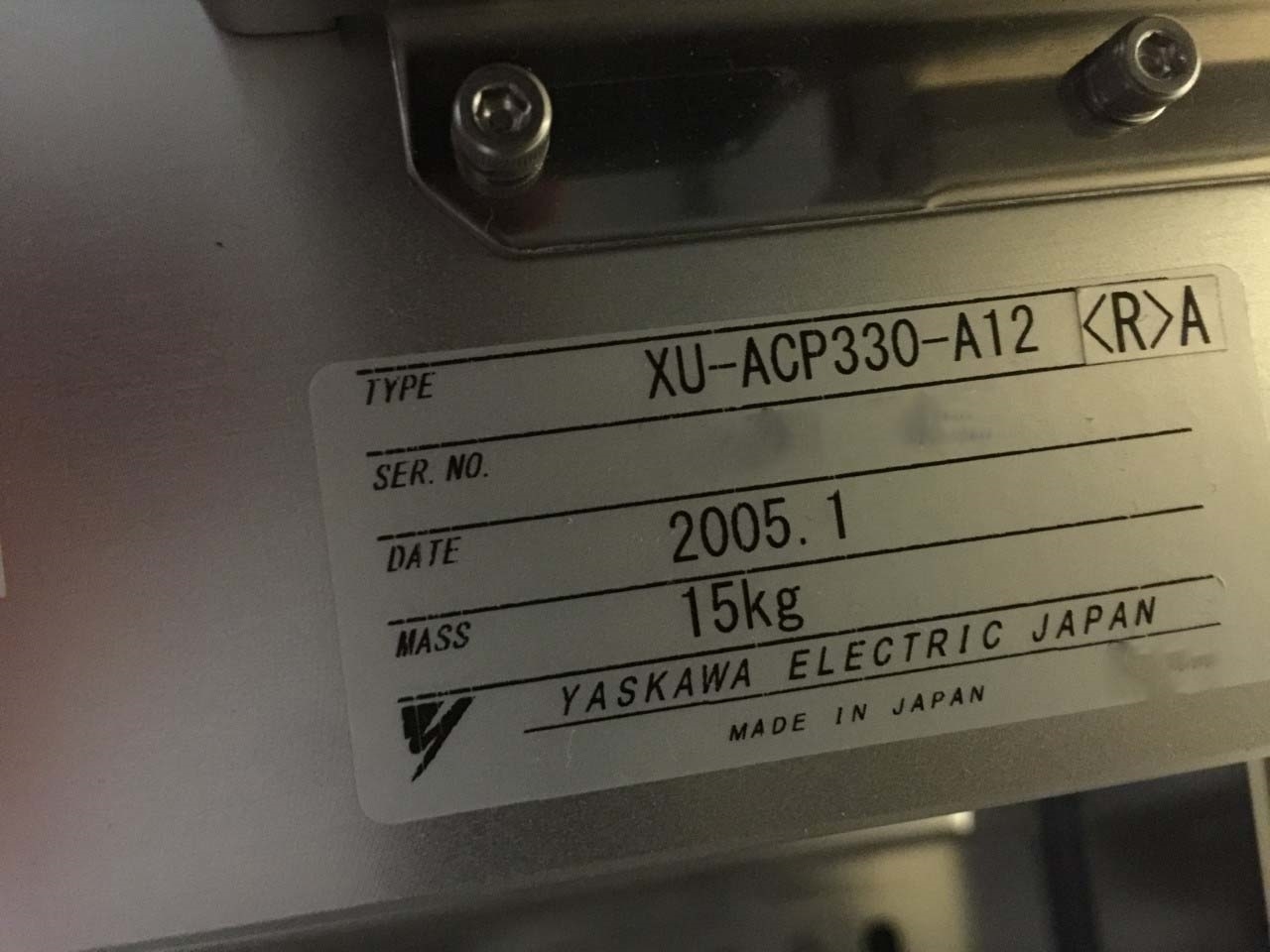

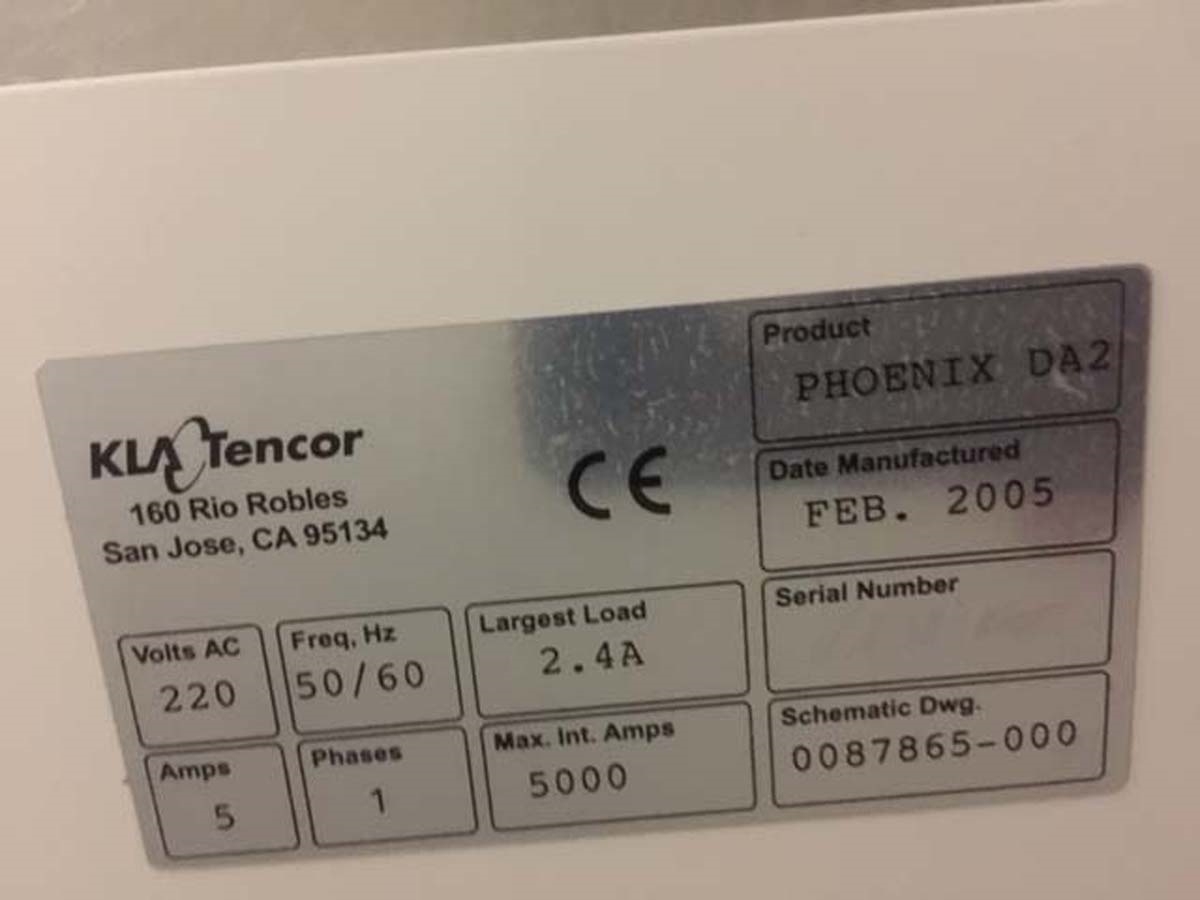

Used KLA / TENCOR Phoenix DA2 #9285836 for sale

URL successfully copied!

Tap to zoom

KLA / TENCOR Phoenix DA2 is a wafer handler designed for the automation of wafer fabrication processes. KLA Phoenix DA2 equipment consists of several components, including a transfer chamber, a sample chamber, a cassette chamber, a pre-alignment chamber, a fine-alignment chamber, two split chambers, and an end-effector. The transfer chamber is used to move wafers between the various chambers of the system, while the sample chamber is used for creating samples and the cassette chamber is used to store processed wafers. The pre-alignment chamber is used for inspecting wafers before they enter the transfer chamber, while the fine-alignment chamber is used for more precise inspection of wafers. The two split chambers are used to split wafers into either two separate parts or two halves, while the end-effector is used for loading and unloading wafers. TENCOR Phoenix DA2 unit has the capability to automatically detect and correct misalignment of wafers throughout the production process. It is capable of performing a variety of tasks, including scanning, cleaning, sorting, placement, probing, and tweezering. The machine is designed to provide accurate alignment for wafers of various sizes and thicknesses, and it can be equipped with a variety of tooling for different tasks. Additionally, Phoenix DA2 is compatible with various software packages and can be customized to meet the specific needs of the user. KLA / TENCOR Phoenix DA2 tool is highly reliable and provides a low cost of ownership. It has a high throughput, low risk of contamination, and a smaller footprint than other systems. The asset is designed to be easy to use, and it includes a user-friendly graphical user interface, support for manual control, and various programmable features. Additionally, the model has a number of safety features, such as automated fault detection and recovery. Overall, KLA Phoenix DA2 is an advanced and reliable wafer handler designed for the automation of fabrication processes. It provides high throughput, low cost of ownership, and a smaller footprint than other systems, making it suitable for a variety of fabrication processes. Additionally, the equipment is equipped with several safety features and has multiple programmable features to meet the specific needs of the user.

There are no reviews yet