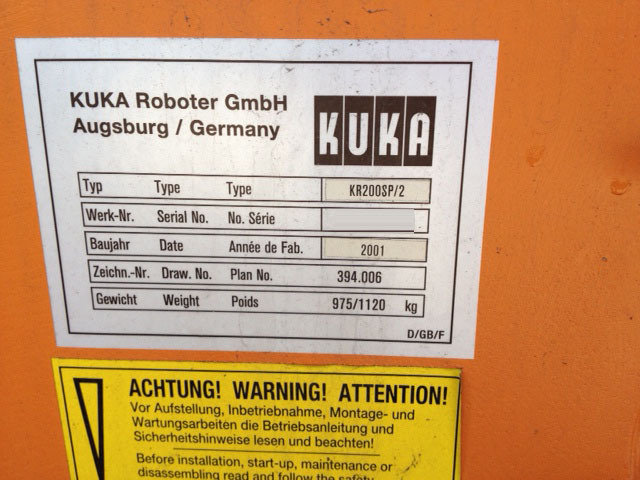

Used KUKA KR 200 #9000715 for sale

URL successfully copied!

Tap to zoom

ID: 9000715

Robots, many available

KRC1 control

200 kg capacity

2.5 m reach

Standard internal I/O

Fiber optic interbus cards available.

KUKA KR200 is an automated wafer handling equipment commonly used in the semiconductor industry. It is a pre-programmable system that can be quickly configured to operate various wafer manufacturing processes such as wafer sorting, loading/unloading, palletizing/unpalletizing, and assembly/disassembly. KR200 is a mobile gantry which allows for a range of movement to accommodate specific job requirements. Its modular design provides flexibility to expand and reconfigure the unit to meet changing production needs. KUKA KR200 can accommodate up to eight wafer carriers, including the carrier size and orientation, to maximize manufacturing space efficiency. The robot is powered by a PC-based controller with a Windows XP operating machine, which provides users a user-friendly interface. Via the interface, various features can be controlled, including the wafer carrier manipulation, wafer sorting, palletizing and unpalletizing, and assembly/disassembly. KR200 uses a sensory control tool to control the position of each wafer and this information is used to control the robot's motion. This asset can also detect obstacles, making it well-suited for industrial use. In addition to this, the robot is also equipped with several safety features, including speed limitation to prevent tipping or bouncing of wafers, an emergency stop switch, so if there is a malfunction the robot will stop functioning and an emergency brake model to prevent a potential collision. KUKA KR200 is an affordable and efficient wafer handling equipment designed to maximize production line efficiency. The system is designed to be easy to learn and use, making it a great choice for any factory looking to increase its efficiency and overall production.

There are no reviews yet