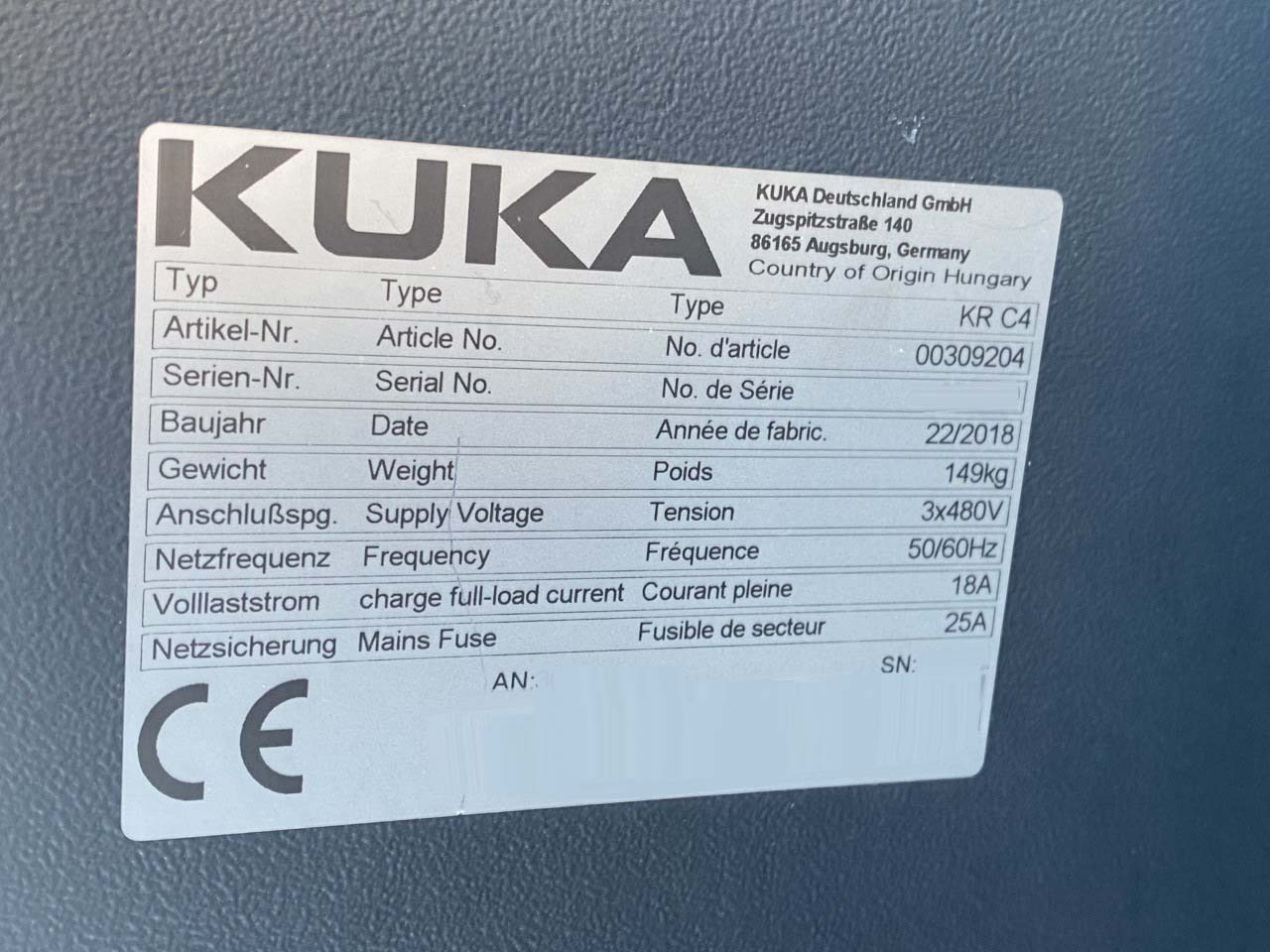

Used KUKA KR C4 #293601013 for sale

URL successfully copied!

Tap to zoom

KUKA KR C4 is a wafer handler that is designed to support the semiconductor-manufacturing processes such as wafer mapping, wafer washing, wafer scanning and wafer alignment. It is an automated machine with an extendable wafer pick up arm. It can pick up, move, and place wafers with the rigid, collapsible, and low center of gravity design of the pick up arm, allowing it to remain stable during operation. KUKA KRC4 is equipped with a two-axis wafer scanner that utilizes two linear motors to effectively drive the wafer scanning movement. The scanner can reach high speeds, up to 2000mm/s, allowing for shorter machining time. The high accuracy motor controls with a 7-wire Sigma-Delta encoder ensures quick and accurate placement of wafers during the machining process. The device is also outfitted with an automated vision system that enables KR C4 to accurately identify wafer positions even when the wafers are moved back and forth. It is also designed to have a long operating life, with a service life of up to five years. The handling capabilities of KRC4 are also designed to meet the demanding needs of the semiconductor industry. It is capable of picking up, transferring, and placing up to 8 inch diameter wafers, and can also handle thin wafers, as thin as 0.1mm, without fear of partial breakage. It can also be used for the precision cleaning of wafers and for wafer alignment. The control system of KUKA KR C4 is equipped with a high speed 32-bit microprocessor, which allows for high response times and rapid entry of commands. The user interface is designed to be simple and intuitive, allowing for a quick learning curve. The device can be operated locally via Control Panel PC or remotely through the Ethernet or serial connection. In summary, KUKA KRC4 is a powerful, automated machine designed for the semiconductor industry. It's highly accurate motor controls combined with its extendable pick up arm allows for accurate placement of wafers even when moving them back and forth. Its two-axis wafer scanner can reach high speeds and its automated vision system allows for accurate wafer identification. Finally, its user interface is designed to be simple, allowing for a quick learning curve.

There are no reviews yet