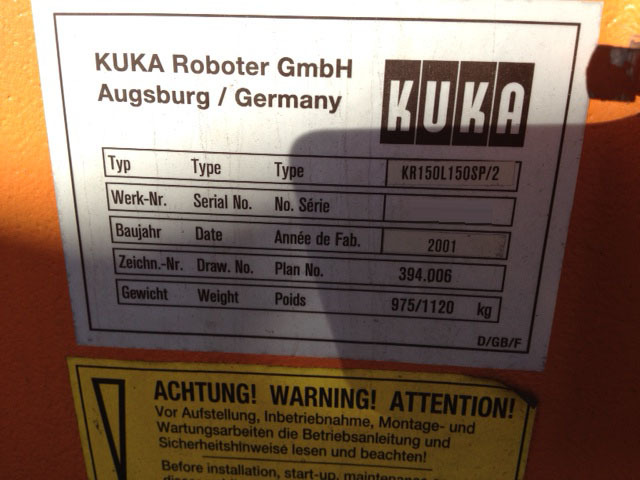

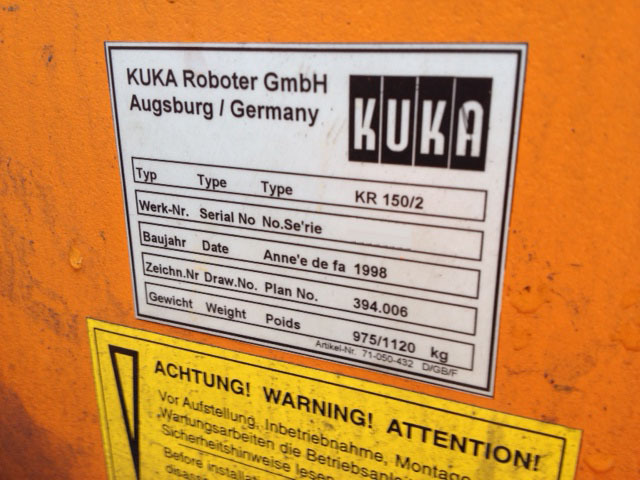

Used KUKA KR150 #9000713 for sale

URL successfully copied!

Tap to zoom

ID: 9000713

Robots, many available

KRC1 control

150 kg capacity

2.5 m reach

Standard internal I/O

Fiber optic interbus cards available.

KUKA KR150 is a robotic arm wafer handler designed specifically for industrial use. It is a movable arm that can carry out a variety of tasks related to wafer fabrication and handling, including transferring wafers from one process station to another, separating and feeding wafers for deposition, and packaging of wafers into cassettes. This robot is built on the foundation of an industrial grade aluminum construction and has a rugged design for durability and dependability. This robotic arm has a 6-axis motion system that allows for a wide range of movements and motions. It operates with a 5-powered axis controller for precise movement and manipulation of materials. It is equipped with a two-phase linear and rotary encoder that provides precise control over motion, and it supports up to three external sensors for accurate position detection and feedback. KR150 robot has a payload capacity of up to 150kg and a maximum load weight of 400kg. This robot is designed to work seamlessly with other industrial automation equipment such as process stations and controllers. It has a modular design with all the necessary components fitted in one unit. KUKA KR150 has a Fieldbus communications interface and is capable of connecting to other devices. It includes a tool changer that is compatible with various tooling and devices that help with wafer fabrication tasks. The robot comes with a software suite that simplifies programming and operation. It supports a range of programming languages including SCILAB, RobotC, and PLCOPEN. It also supports the use of Control Domain Programming (CDP), allowing users to program the robot to relax the movements and movements it has to do, instead of setting each successive step. KR150 is equipped with a variety of safety components such as E-stop buttons, safety mats, light curtains and laser scanners. It also features an industry-standard safety interface that meets safety requirements for industrial applications, allowing for seamless integration with other systems and equipment. The robot has a wide range of operational parameters that can be adjusted to influence the robot's performance depending on application requirements. KUKA KR150 robot has a variety of features that make it a great choice for use in industrial applications. It is reliable, flexible, and capable of meeting the demands of complex wafer fabrication and handling processes. Its modular design provides for efficient integration and it is compatible with various industrial automation systems and components. The addition of the safety components and the user-friendly programming and operation features also make KR150 an ideal choice of robotic arm for industry use.

There are no reviews yet