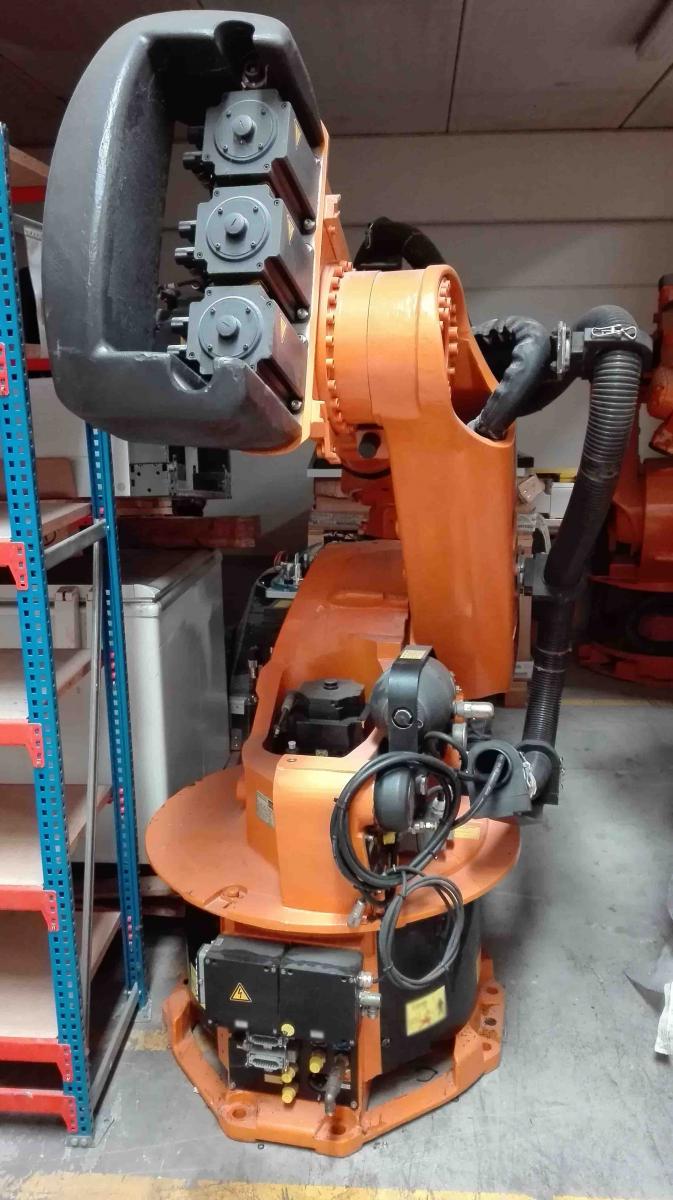

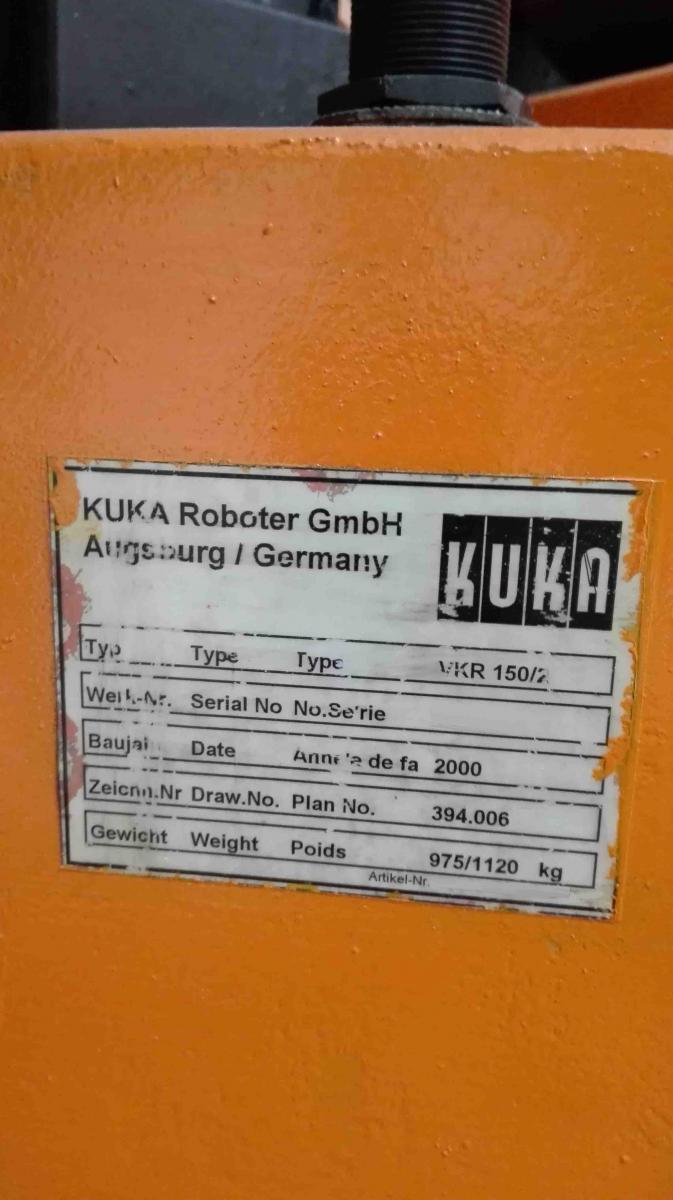

Used KUKA Series 2000 #9180904 for sale

URL successfully copied!

Tap to zoom

ID: 9180904

Vintage: 2000

Robot

(5) Rating classes

Payloads: 150 to 270 kg

Different arm extensions

Mounting variants for the ceiling / floor

Repeatability: ±0.06 mm

Type: KR 150-2:

Maximum reach: 2,700 mm

Rated payload: 150 kg

Suppliment load, arm/link arm/rotating column: 50 / 100 / 300 kg

Suppliment load, arm + link arm, maximum: 100 kg

Maximum total load: 550 kg

(6) Axes

Mounting position: Floor, ceiling

Variant: Cleanroom, foundry

Positioning repeatability: ±0.06 mm

Controller: KR C2 edition2005

Temperature during operation: +10°C to +55°C

Protection classification: IP 65

Robot footprint: 1,006 mm x 1,006 mm

Connection: 7.3 kVA

Noise level: < 75 dB

Type: KR 150 L130-2:

Maximum reach: 2,900 mm

Rated payload: 130 kg

Suppliment load, arm/link arm/rotating column: 50 / 100 / 300 kg

Suppliment load, arm + link arm, maximum: 100 kg

Maximum total load: 530 kg

(6) Axes

Mounting position: Floor, ceiling

Variant: Cleanroom, foundry

Positioning repeatability: ±0.06 mm

Controller: KR C2 edition2005

Temperature during operation: +10°C to +55°C

Protection classification: IP 65

Robot footprint: 1,006 mm x 1,006 mm

Connection: 7.3 kVA

Noise level: < 75 dB

Type: KR 150 L110-2

Maximum reach: 3,100 mm

Rated payload: 110 kg

Suppliment load, arm/link arm/rotating column: 50 / 100 / 300 kg

Suppliment load, arm + link arm, maximum: 100 kg

Maximum total load: 510 kg

(6) Axes

Mounting position: Floor, ceiling

Variant: Cleanroom, foundry

Positioning repeatability: ±0.06 mm

Controller: KR C2 edition2005

Temperature during operation: +10°C to +55°C

Protection classification: IP 65

Robot footprint: 1,006 mm x 1,006 mm

Connection: 7.3 kVA

Noise level: < 75 dB

Speed with rated payload: 150 kg

Axis data Range (s/w) Speed with rated payload

Axis 1 (A1) ±185° 110°/s

Axis 2 (A2) 0°/–146° 110°/s

Axis 3 (A3) +155°/–119° 100°/s

Axis 4 (A4) ±350° 170°/s

Axis 5 (A5) ±125° 170°/s

Axis 6 (A6) ±350° 238°/s

Speed with rated payload: 130 kg

Axis data Range (s/w) Speed with rated payload

Axis 1 (A1) ±185° 105°/s

Axis 2 (A2) 0°/–146° 110°/s

Axis 3 (A3) +155°/–119° 95°/s

Axis 4 (A4) ±350° 170°/s

Axis 5 (A5) ±125° 170°/s

Axis 6 (A6) ±350° 238°/s

Speed with rated payload: 110 kg

Axis data Range (s/w) Speed with rated payload

Axis 1 (A1) ±185° 105°/s

Axis 2 (A2) 0°/–146° 110°/s

Axis 3 (A3) +155°/–119° 93°/s

Axis 4 (A4) ±350° 170°/s

Axis 5 (A5) ±125° 170°/s

Axis 6 (A6) ±350° 238°/s

2000 vintage.

KUKA Series 2000 automated wafer handler is a robotic arm integrated into a general purpose industrial robot system. It is capable of handling wafers up to 18 inches in diameter, as well as delicate optoelectronic components. The arm is equipped with a high-resolution encoder to ensure precise movements and a vacuum suction cup tool for wafer handling to protect fragile components. The vacuum suction cup tool is highly flexible and can be configured to accept wafers in different shapes and sizes. Series 2000's extendable arm has a maximum reach of 8 inches and a repetition accuracy of up to 0.015 mm. It is equipped with an advanced vision system for precise recognition of wafer edges, as well as image processing routines for wafer occlusion detection. An industrial-grade PC with KUKA KUKA Studio software runs the robot arm and ensures a reliable operation. KUKA Series 2000 is capable of carrying out a wide range of wafer-handling tasks. It is able to pick up wafers from different sources, transfer them to various stages, and perform precision positioning operations. It can also align wafers in complementary ways, such as perfectly fine alignment and pre-alignment. Furthermore, it is equipped with a fast drop and pick mechanism, which allows for speedy manipulation of multiple wafers at once. Series 2000 is extensively used in the semiconductor and photonics industries. It provides a reliable and accurate solution for precise wafer-handling operations in harsh industrial environments. It is extremely versatile and reliable, made of lightweight yet robust components, and requires a minimal amount of maintenance. Thanks to its compact size, KUKA Series 2000 can be easily integrated into existing manufacturing lines and used for both new and existing processes.

There are no reviews yet