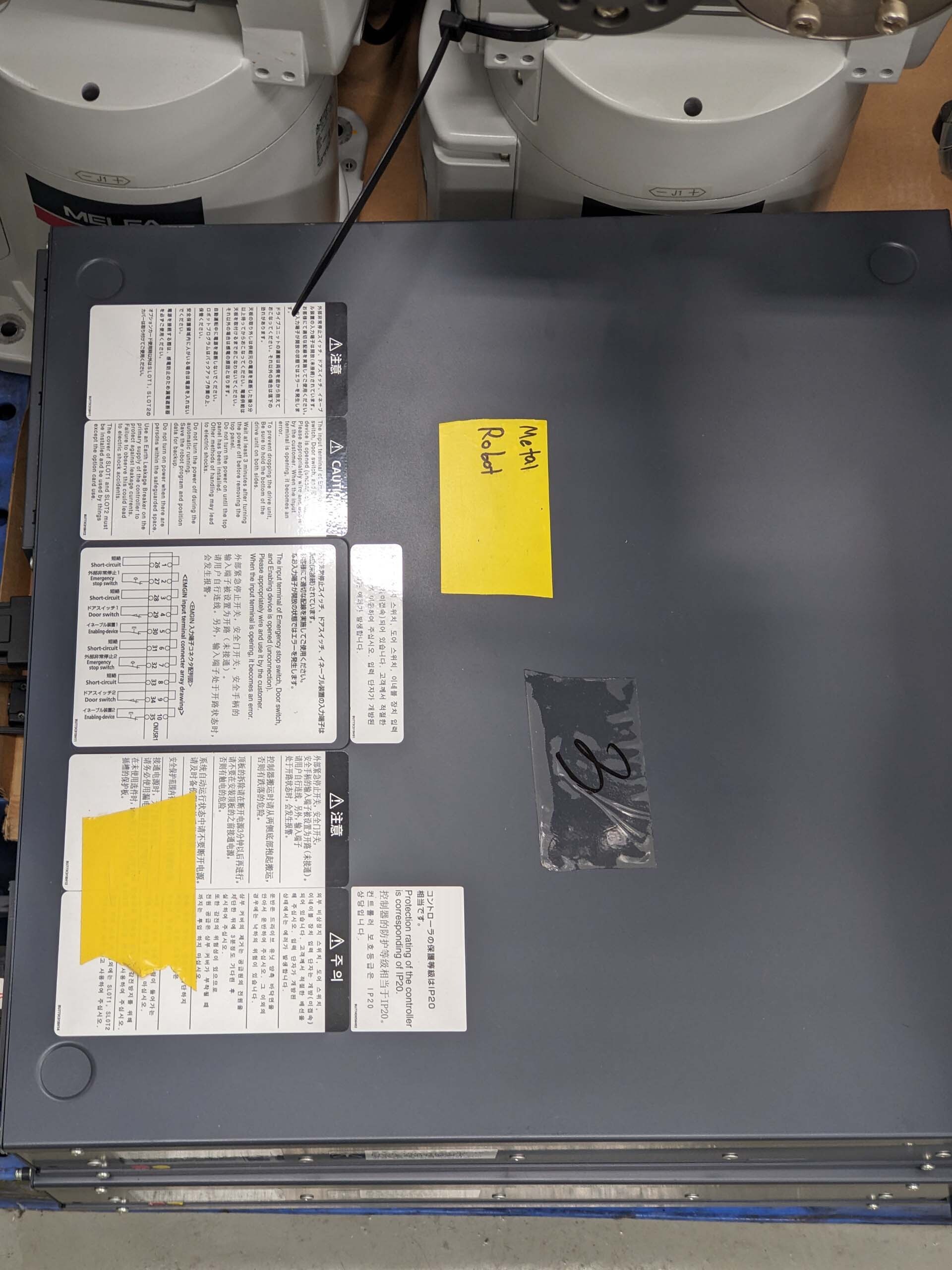

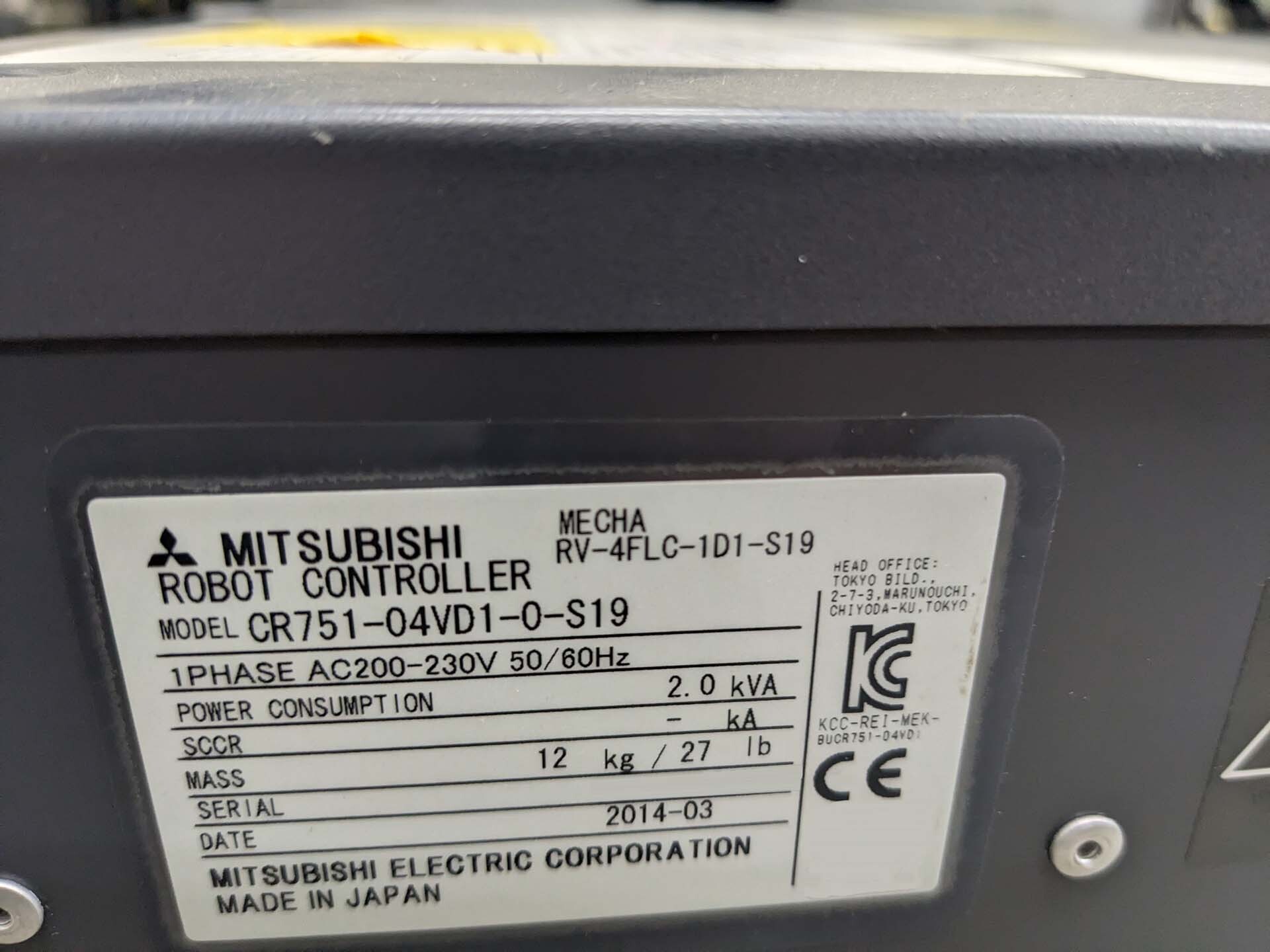

Used MITSUBISHI CR751-04VD1-0-S19 #9411584 for sale

URL successfully copied!

Tap to zoom

MITSUBISHI CR751-04VD1-0-S19 Wafer Handler is a highly advanced electromechanical and chemical handling equipment designed to support a wide variety of semiconductor and device production processes. This system is designed to provide clean and repeatable handling of up to 49 wafer sizes and thicknesses ranging from 1 mil to 20 mils. In addition, the unit has an operational capability of up to 400 wafers per hour. At the heart of the CR751 is an integrated wafer handler which comprises a full machine architecture for process automation and programmable control. This includes a mainframe, control tool, and a distributed control loop incorporating advanced vibration control technology. The asset is capable of supporting the most demanding and sensitive process steps. The model itself is comprised of five main components, a loader, a unloader, a wafer carrier, a manipulator, and a vision equipment. The loader includes a twin conveyor belt drive assembly which enables wafers to be quickly and easily loaded, unloaded, and moved along the assembly line. The unloader is similar in design to the loader and can be used to quickly and easily transport wafers in and out of the cleaning, alignment, or polishing processes. The wafer carrier is designed to safely transport and secure the wafers through the various stages of production, while the manipulator is used to accurately align the wafers on the loading belts to ensure precise loading and unloading. The vision system is a key component of the wafer handler as it provides precise positioning of the wafers as they travel through the production line. It also monitors the quality of the processed wafer to ensure the highest quality standards are met. CR751-04VD1-0-S19 is a highly integrated automated wafer production unit equipped with advanced features that guarantee high precision, repeatable performance and low wafer damage. It is an ideal solution for the diverse semiconductor manufacturing environment, providing an efficient, cost-effective and high-quality solution for wafer production.

There are no reviews yet