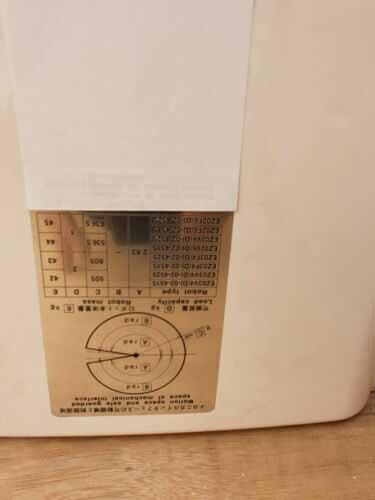

Used NACHI EZ Series #293606739 for sale

URL successfully copied!

Tap to zoom

NACHI EZ Series Wafer Handlers are automated systems designed to move and handle wafers safely and accurately in semiconductor manufacturing processes. The equipment features a highly reliable and repeatable wafer transfer mechanism with a wafer indexing accuracy of up to ±2 mm. EZ Series also features an innovative wafer handling mechanism that can handle wafers up to Ø300mm, enabling handling of large and small wafer sizes simultaneously. With its modular system architecture, NACHI EZ Series can be customized to meet the exact needs of a particular semiconductor manufacturing process. EZ Series offers advanced handling capability with its advanced sensors that allow for precise positioning and alignment. The unit is designed for flexibility in wet and dry applications, as well as in various environments including cleanroom and ambient. An integrated motion control and motion profiles, such as linear or circular motion, are also available. Furthermore, a programmable logic controller (PLC) ensures smooth operation, while also allowing customization through software programming. NACHI EZ Series is an integrated programmable machine that provides high speed and accurate wafer handling. As a single unit, the tool is capable of carrying multiple wafers at once and can be used for transferring wafers quickly between stations. This integration also makes it easier for maintaining and repairing, with minimal downtime and lower cost. EZ Series provides high-speed, reliable and cost-effective wafer fabrication. The asset offers a wide variety of wafer handling capabilities, from small to large wafer sizes. Its modularity also allows users to create custom-tailored systems, which can be further upgraded to meet changing needs. Additionally, the model can be integrated with other advanced automation systems and other complementary equipment, such as furnace, for further automating the process. Overall, NACHI EZ Series offers superior performance and accuracy in semiconductor manufacturing. Its sophisticated design, advanced features and flexibility make it an ideal choice for any manufacturing environment. The equipment also comes with a wide range of safety features, making it an optimal choice for handling wafer fabrication.

There are no reviews yet