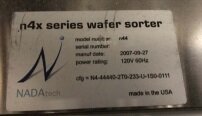

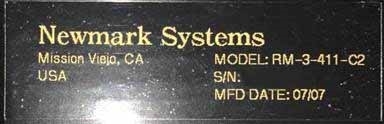

Used NADATECH N44 #9244439 for sale

URL successfully copied!

Tap to zoom

ID: 9244439

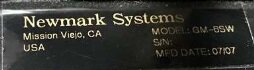

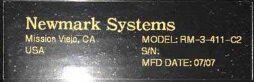

Vintage: 2007

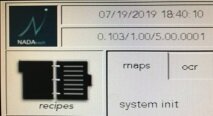

Sorter

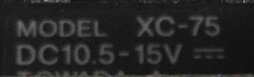

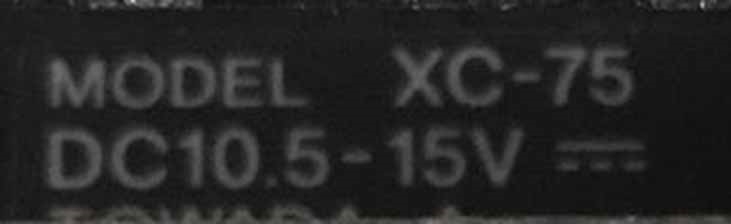

SONY XC-75 OCR Cameras

Pre-aligner:

Aligning time standard mode: 4 Sec

Aligning time high precision mode: 12 Sec

Rotational resolution: 0.015

Linear resolution: 0.00065 mm

Vacuum: 70 kPa

Vacuum sensor triggering pressure: 55 kPa

Vacuum line: 1/8" (Single line)

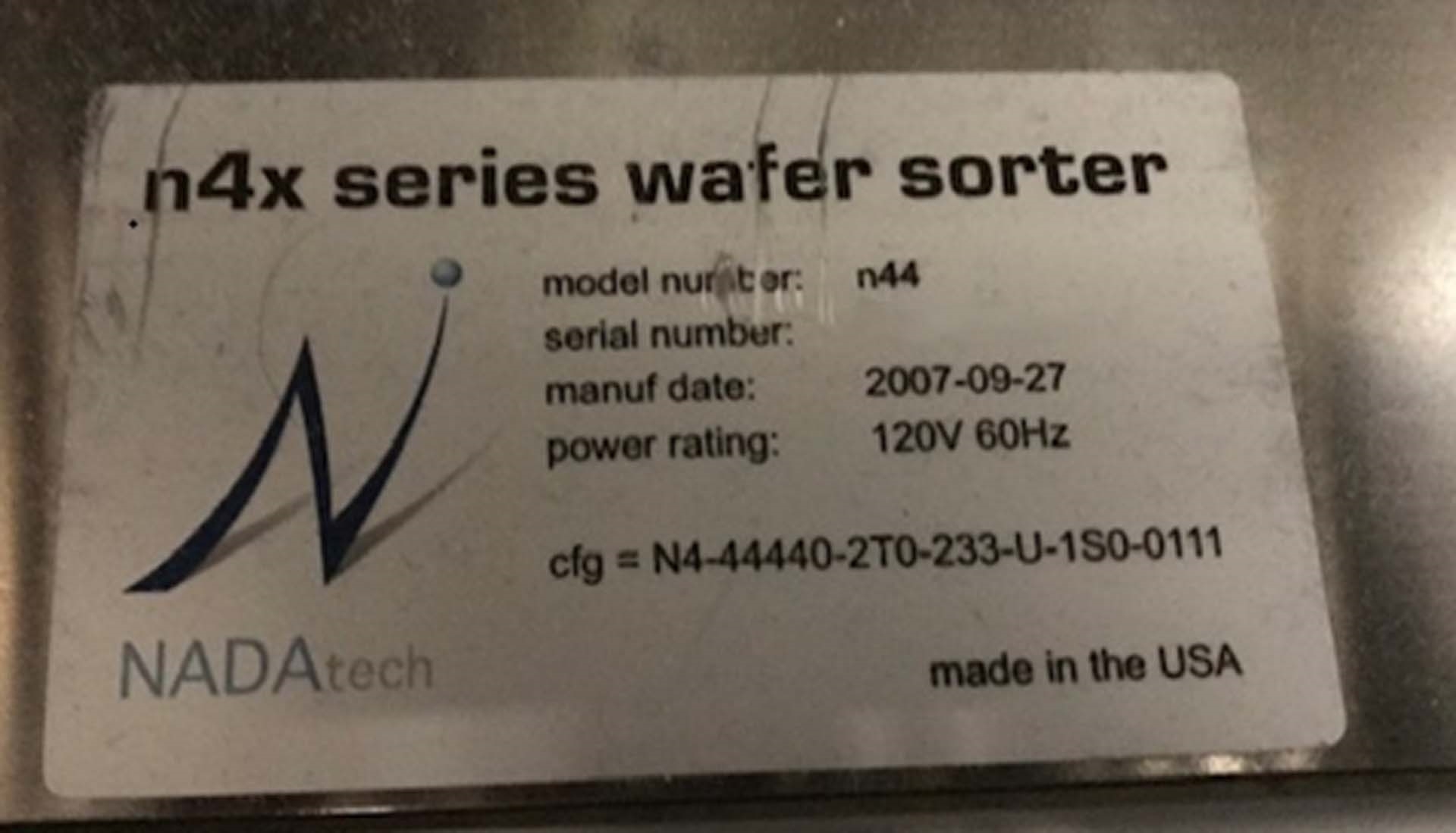

Controller:

Power source: AC 115/230 V, 50/60 Hz

Robot:

Arm retract position: 60° (+/-2)

Rotation range: 540°

Vacuum lines: 100 (Dual vacuum lines) mm (+/-2.0)

Wiring for scanner

Vacuum: Hg 18 (min. requirement)

Robot controller:

Power source: AC 110 V, 50/60 Hz

Standard cable length: 45 mm (+/-4.0)

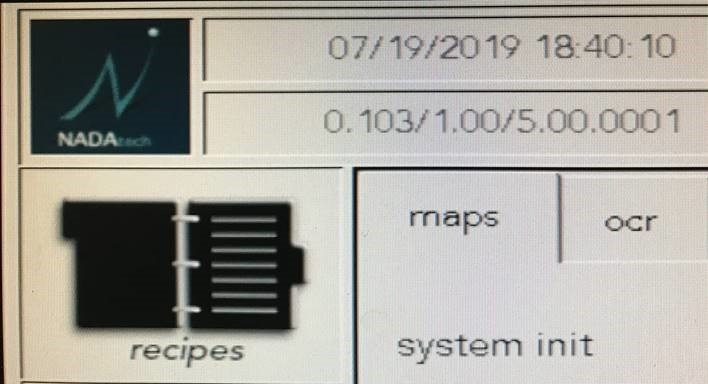

Operating system: Window 2000

2007 vintage.

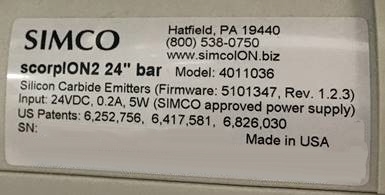

NADATECH N44 Wafer Handler is a fully automated wafer manipulation and sorting equipment designed to process and sort bare silicon wafers in an ultra-clean environment. This system can process up to 50 wafers in one run. It is capable of handling wafers as thin as 75µm and as large as 150mm in diameter. N44 unit contains several individual components. Firstly, it has a HEPA-filtered environment that helps to maintain cleanliness by capturing dust particles and other contaminants. Secondly, there is a SCARA-type robot arm, which allows for precise wafer pickup and placement. Thirdly, a conveyor machine moves wafers from station to station. Fourthly, a vision tool is used for accurate identification of static wafers. Finally, a sorting asset separates different types of wafers. In operation, a bundle of wafers is first placed into the handling chamber. The HEPA-filtered environment helps to keep it clean. The SCARA-type robot arm then picks up one wafer at a time and places it on the conveyor. If needed, the vision model is used to identify the wafer type, and it can then be picked and sorted by the sorting equipment into one of three categories: low-resistivity; high-resistivity; or other. The wafer can then be either placed into a reusable wafer cassette or manually routed to further production steps. Finally, NADATECH N44 Wafer Handler is equipped with a microprocessor providing control of all components and precise data logging. This ensures that full traceability exists for all processed wafers. In conclusion, N44 Wafer Handler is a versatile, efficient and ultra-clean system for handling, processing and sorting of bare silicon wafers. With its accuracy and data logging, it can provide a safe and reliable wafer production process. By providing an ultra-clean environment, it can also help improve the quality of the wafers produced.

There are no reviews yet