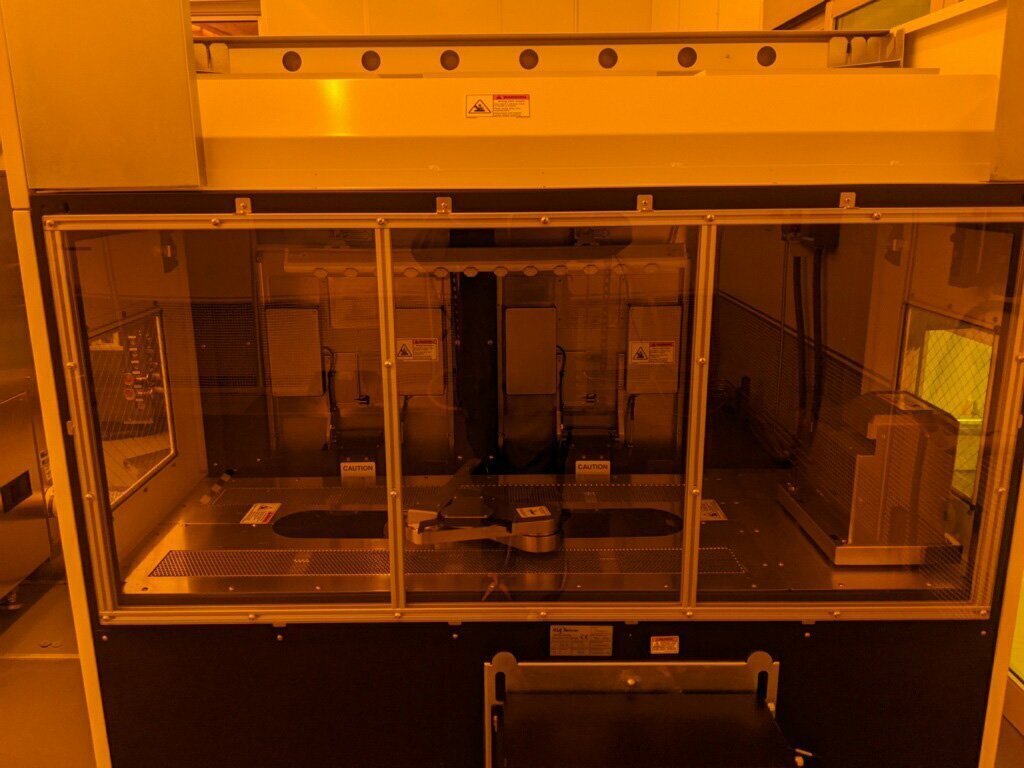

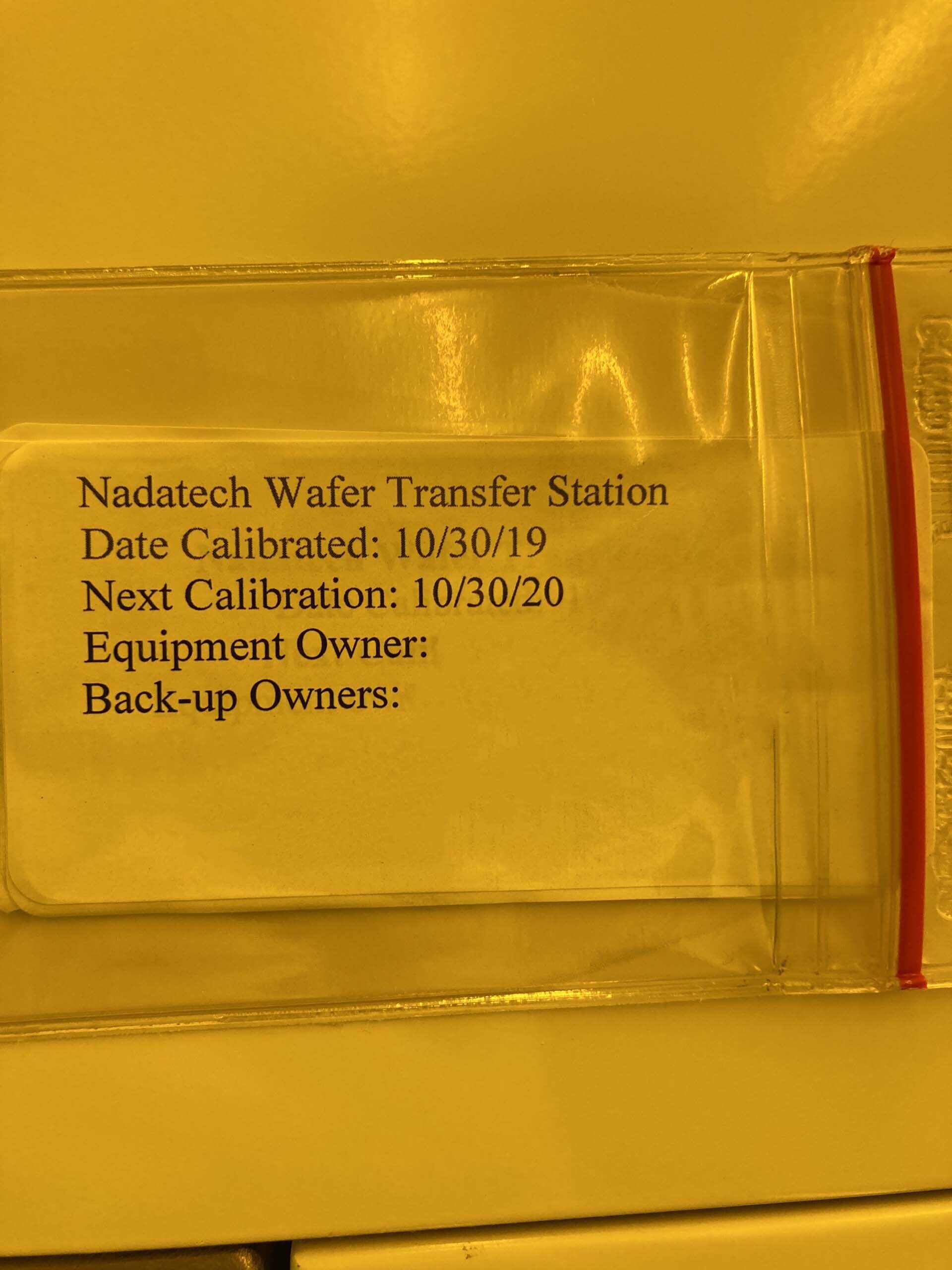

Used NADATECH RS2 #9314753 for sale

URL successfully copied!

Tap to zoom

ID: 9314753

System

Steel frame

Steel bottom plate

Powder coated panels

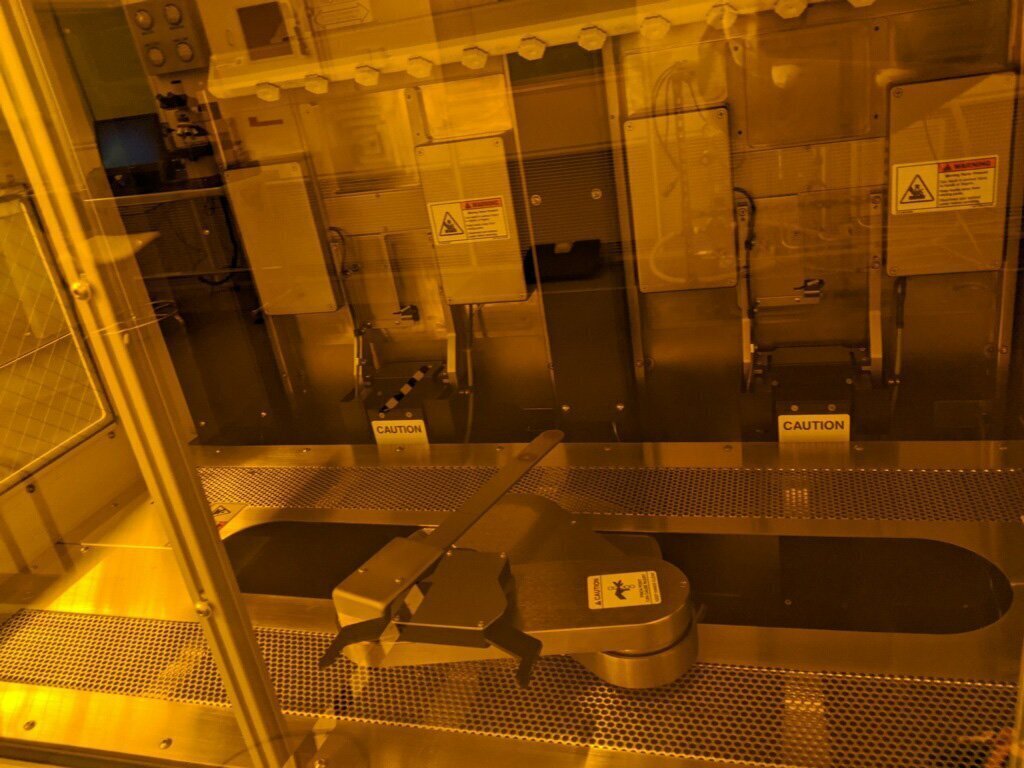

EQUIPE ATM-407 Robot and robot track with vacuum backside

NADATECH Vacuum end effector with SURESCAN for wafer carrier mapping

(2) ASYST Loadports, 12" for FOUP and FOSB

INTEL System operating: >1,000 MHz

RAM: 1G

SSD HD: 80G

DVD Drive

LCD Monitor, 17"

Mini keyboard

Trackball mouse

Operating system: Windows XP.

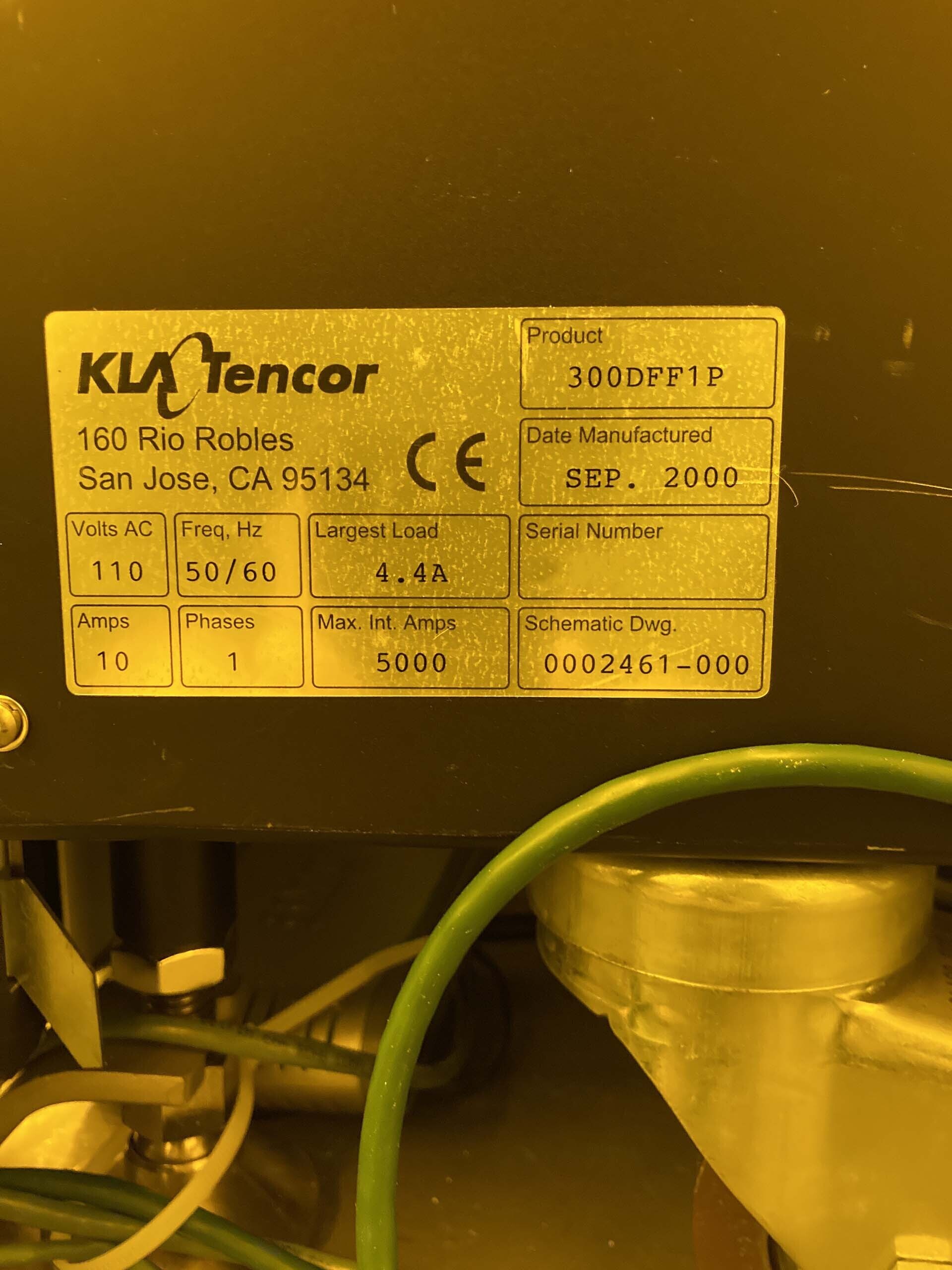

NADATECH RS2 is an advanced wafer handler designed for precise, automated handling and control of semiconductor wafers. Its advanced design provides high precision movement, excellent process control, and exceptional versatility. RS2 features a 5-axis robotic arm with a maximum reach of 755mm and a delta head with 6 degrees of freedom that can precisely handle wafers up to 12-inches in size. Additionally, its 3-dimensional counter balancing feature provides superior accuracy when handling wafers. NADATECH RS2 is equipped with an automated pneumo-electric particle detection equipment, designed to detect imperfections, scratches and particles on the surface of the wafer and automatically adjusts its handling instructions for safe and precise operation. Additionally, a precision stage is included for automated multi-axis alignment of wafers. RS2 also includes a temperature ventilation system to maintain optimal wafer environmental conditions. NADATECH RS2 boasts a high-speed open loop servo unit, enabling highly accurate and repeatable positioning with consistent and repeatable accuracy to within 25 microns. This advanced wafer handler can hold up to 50 wafers at a time based on wafer diameter and thickness, making it ideal for high-volume applications. Its advanced wafer chucking mechanism further increases the flexibility of using RS2 for handling wafers of various sizes, shapes, and materials. As a result of its exceptional precision and accuracy, NADATECH RS2 is the ideal solution for applications involving thin wafer handling, ultra-precision assembly, and other ultra-high precision requirements. For added safety and convenience, RS2 is designed to operate both in a fully automated or manual mode. This flexibility allows the user to use the machine for manual operation when needed or to employ fully automated operation for higher throughput. Additionally, NADATECH RS2 includes a host of features such as wafer thick gauging, auto retrieval, programmable pick and place routines, and user-defined part handling libraries for maximum process control. Overall, RS2 is the perfect solution for precise handling and control of semiconductor wafers. Its advanced design provides exceptional versatility, precision, and accuracy for both high-volume and ultra-precision wafer handling applications.

There are no reviews yet