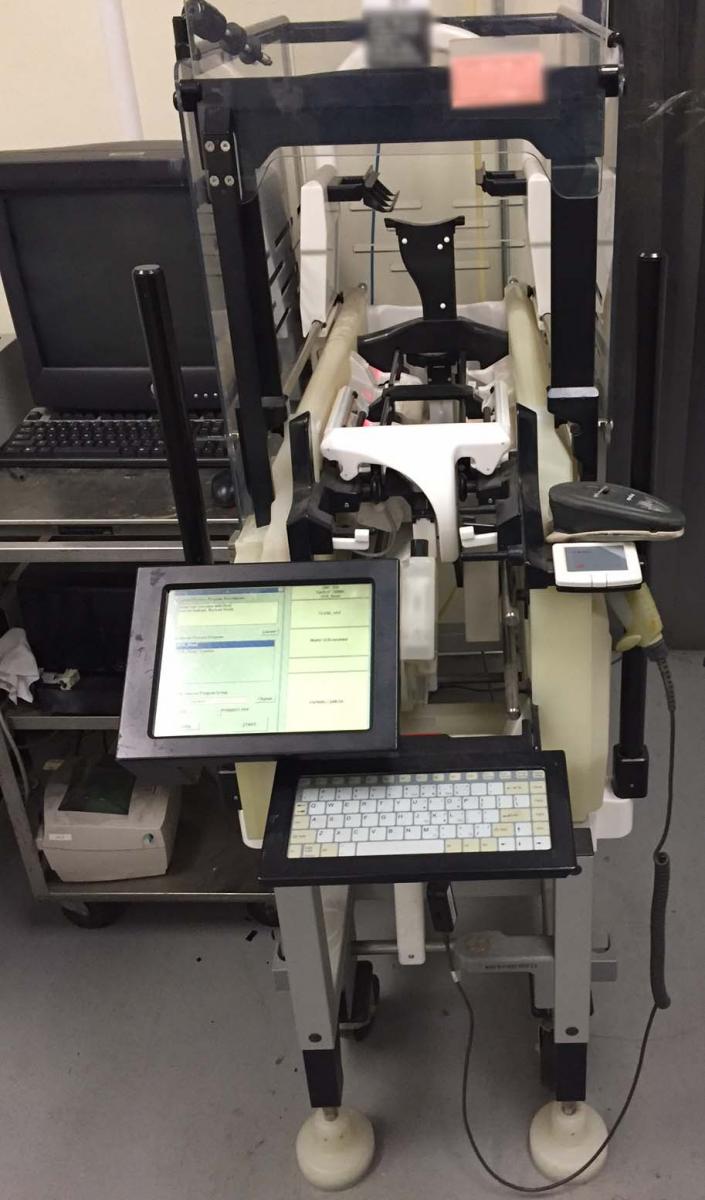

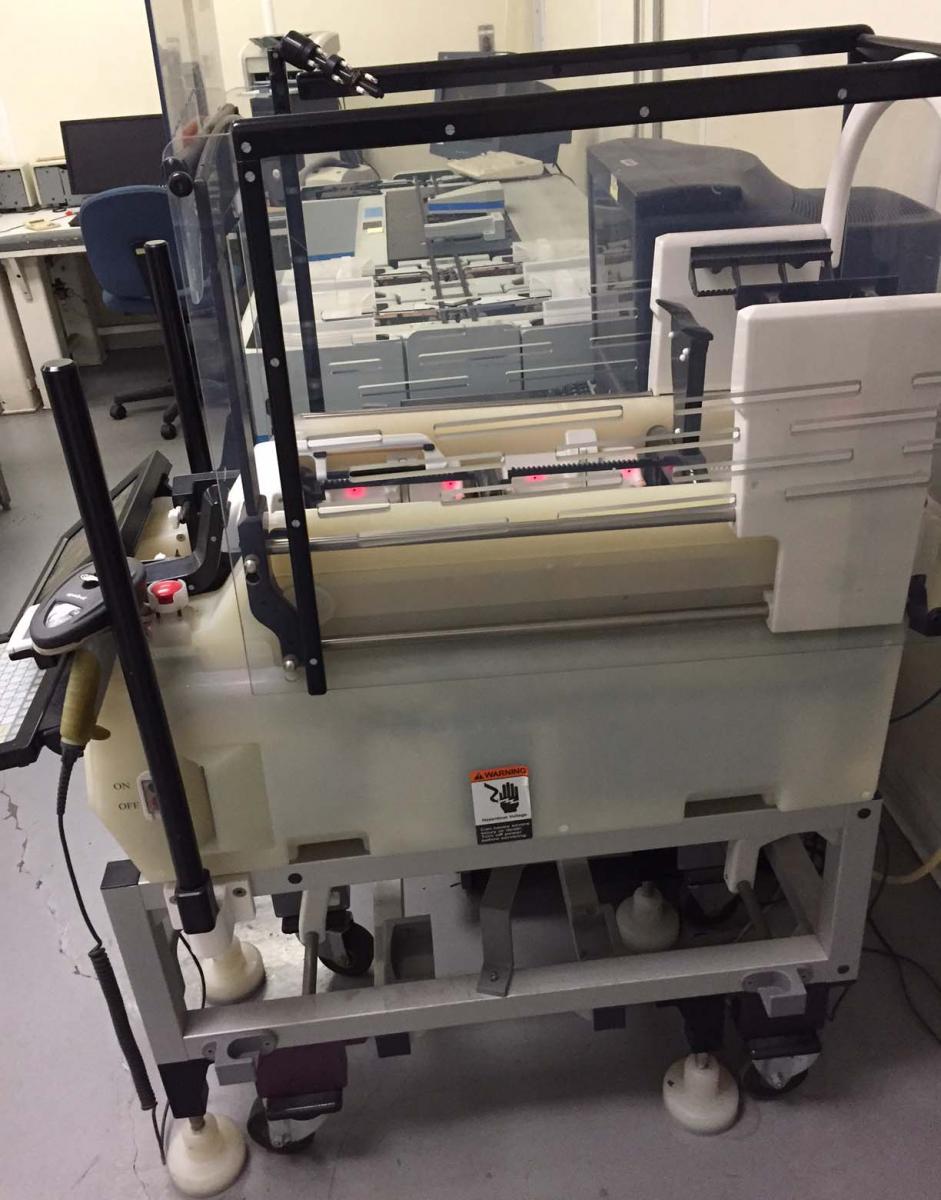

Used RECIF IDLW6MR #9174912 for sale

URL successfully copied!

Tap to zoom

RECIF IDLW6MR is a wafer handler equipment designed for the automated processing of 300mm wafers in semiconductor fabrication facilities. This high-performance system improves process control and throughput while maintaining a high level of accuracy. IDLW6MR wafer handler is designed to meet and exceed the semiconductor process standards of the industry. It features a modular design, with six independent carousels for handling up to 300mm wafers. This wafer handler has a 6-inch pitch up to 1.7mm, and a 10-inch pitch up to 2.7mm. It also includes a pallet station for easy loading and unloading of wafers and an optional pedestal station for maintenance purposes. Its central controller unit provides programming control and multiple options for advanced functionality. It also supports single and double-track robotics, as well as a single-track conveyor. RECIF IDLW6MR wafer handler is equipped with a high-precision Loader/Unloader (LU) and a device stage for wafer transfers. The LU features a four-axis robot unit, three vacuum arms, and three wipers for loading and unloading wafers into 5-inch or 300mm cassettes. The device stage, on the other hand, is designed to improve process chamber loading speed and maximize throughput. It offers sensor-based loading/unloading and an automated transfer mechanism between the Chamber and the LU. IDLW6MR wafer handler is equipped with advanced wafer alignment capabilities, including top and bottom double-arm alignment. The machine also integrates sensors for in-situ monitoring, providing real-time data of wafer and tool status. Meanwhile, its integrated touch-screen operator interface allows coordinated control and input of process parameters. RECIF IDLW6MR wafer handler is designed for ease of use and reliability, with various safety features including anti-reverse switch, temperature-controlled heaters, and an 8-point electrical interlock asset. Additionally, its modular design allows it to be adapted to various applications quickly and efficiently. It is designed for optimal performance in the most demanding semiconductor manufacturing environments.

There are no reviews yet