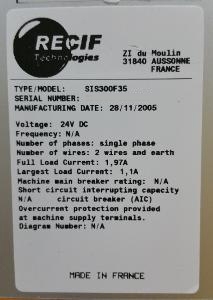

Used RECIF SIS300F35 #9194928 for sale

URL successfully copied!

Tap to zoom

RECIF SIS300F35 is an automated wafer handler designed for industrial use. It is capable of loading, unloading, and transferring semiconductor, disk, flat panel display (FPD), micro-electro-mechanical systems (MEMS), and optical parts wafers from front-opening unified pod (FOUP) and nanochuck containers. SIS300F35 is a three-axis wafer handler, with a robotic arm mechanically moving a wafer sled from the FOUP or nanochuck container, across the x, y, and z-axis to the target positions. To ensure safe and precise handling, the board-level controller of the robot arm is equipped with a high-accuracy encoder, torque control, and an emergency stop switch. The weights of the wafer sled and wafer cassette range from 1kg to 4kg. It also features sample optics capability for alignment during transport, as well as configurable clamping of carriers and wafers. A USB port makes is possible to plug in a diagnostic tool or a memory stick with upgrade files. This is complemented by another port to allow the user to connect an external data switch for remote monitoring. RECIF SIS300F35 is equipped with a touchscreen and a text-based user interface, providing a straightforward way for operators to handle their programs. A built-in database stores up to 500 recipes, which contain detailed instructions on handling wafers within the specified environment. SIS300F35 also supports protocols such as Pinpoint, SPEEDbus, and ICOS, allowing it to be linked to other peripheral devices in the same system. RECIF SIS300F35 provides an optimum balance of wafer handling speed and safety. An intelligent wafer transfer queue system allows multiple wafers to be processed at once, while maintaining a safe distance and maintaining even spacing throughout the process. An optical detection system activates when the wafer sled and wafer cassette approach each other, specifically during unloading and loading, to ensure any misalignment is corrected and the parts are correctly handled. Finally, SIS300F35 is available in both standard Horizontal (H) and Vertical (V) configurations to suit different automation requirements.

There are no reviews yet