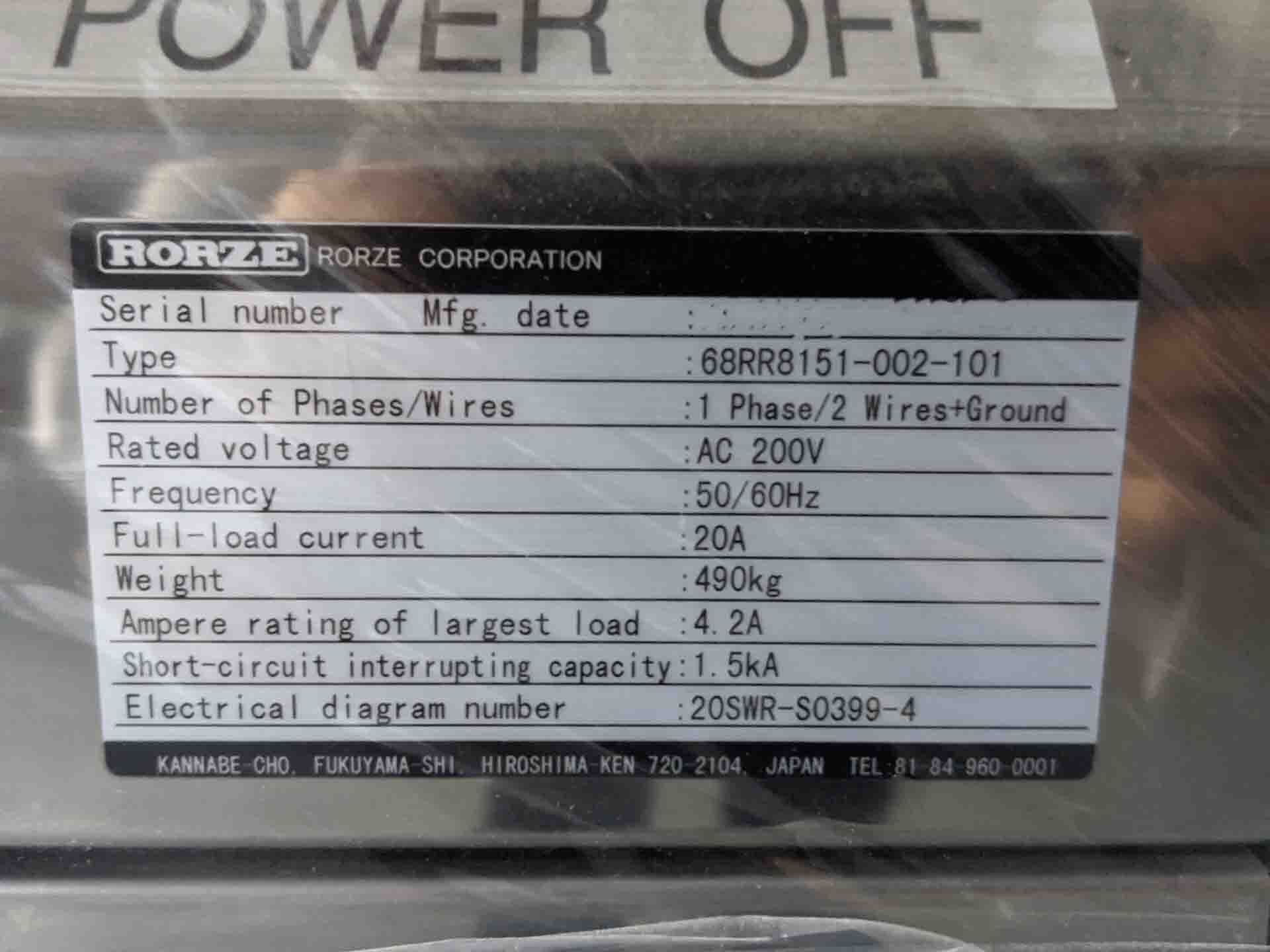

Used RORZE 68RR8151-002-101 #293635474 for sale

URL successfully copied!

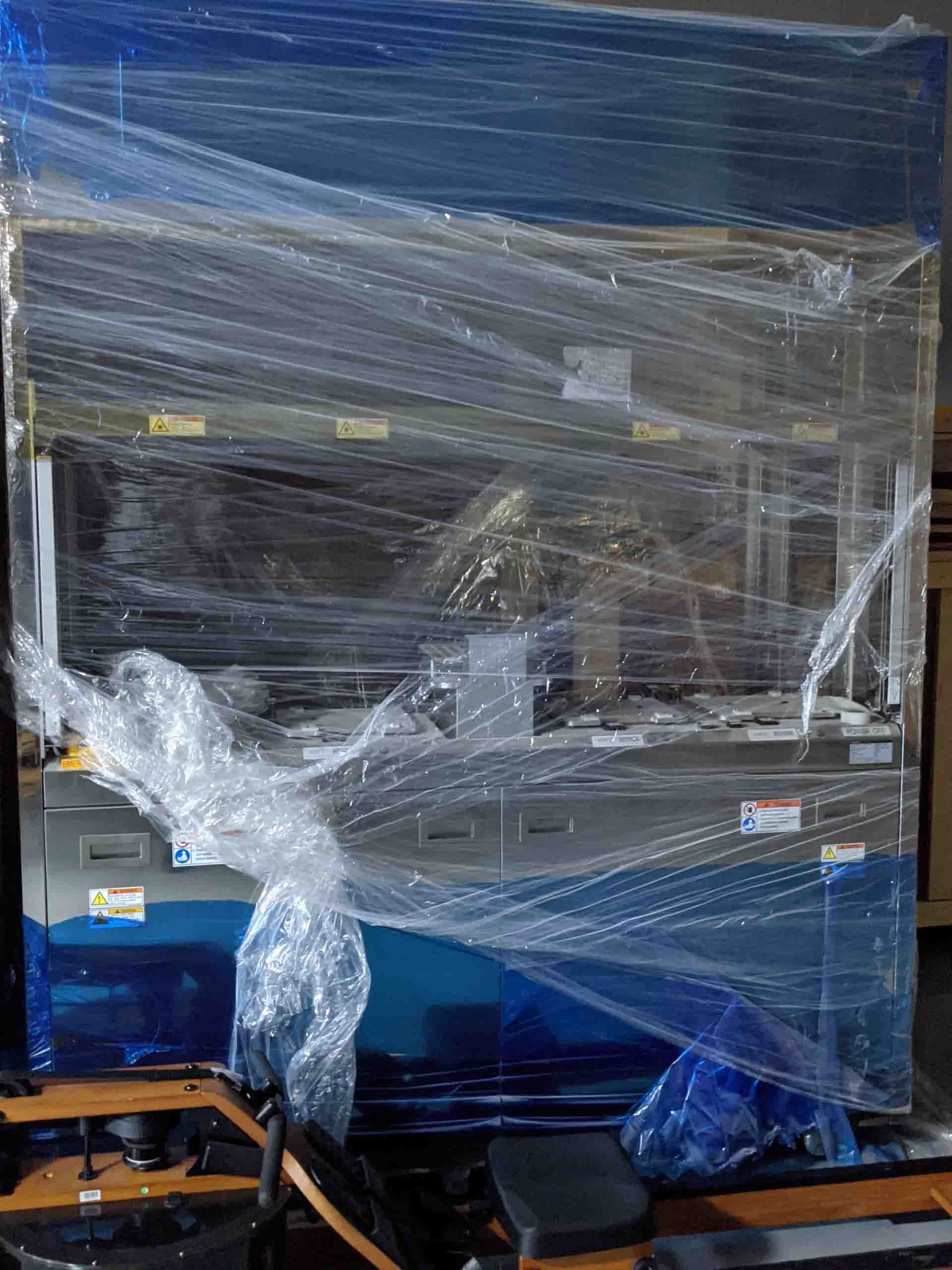

Tap to zoom

RORZE 68RR8151-002-101 Wafer Handler is an automated wafer handling equipment designed for 200mm and 300mm semiconductor manufacturing processes. It has a multi-level design that allows for the handling of multiple cassettes or FOUP (Front Opening Unified Pod) and cells, as well as for the transfer and positioning of semiconductors. 68RR8151-002-101 is equipped with a CCD camera, X and Y high speed synchronized motion platform, a high accuracy positioning system and a robotized arm with an anti-collision function. The high accuracy positioning unit, which utilizes a paddle tray, ensures wafer alignment and positioning with extreme precision. The robot arm, which moves along the X-axis and Y-axis, picks up the wafers with its vacuum suction cups and places them in the cassette. RORZE 68RR8151-002-101 is able to process up to 60 wafers per hour, with a maximum wafer size of 150mm x 150mm. It has a flexible mounting machine that enables it to be installed in various orientations. This tool is designed to be compatible with various production lines and can be combined with other RORZE wafer handlers, such as RORZE 68RR6003. 68RR8151-002-101 is equipped with a sophisticated array of prevention and detection functions, such as a pressure sensor to detect vacuum, a lift sensor to monitor the elevation of the wafer, and a tilt sensor to detect a misaligned wafer. The pressure sensor monitors the vacuum pressure of the suction head, while the lift sensor monitors the position of the wafer. The tilt sensor is used to detect any misalignment that may occur during the wafer transferring process, and will alert the user in the event of any misalignment. RORZE 68RR8151-002-101 also features an interface for computer control and an easy to use GUI for configuration and maintenance. This ensures that the operator can easily set up and maintain the asset, as well as monitor its operation. In summary, 68RR8151-002-101 is a highly capable wafer handling model designed for semiconductor manufacturing applications. Its reliability, accuracy and speed make it an excellent choice for any semiconductor factory looking to improve their semiconductor manufacturing process.

There are no reviews yet