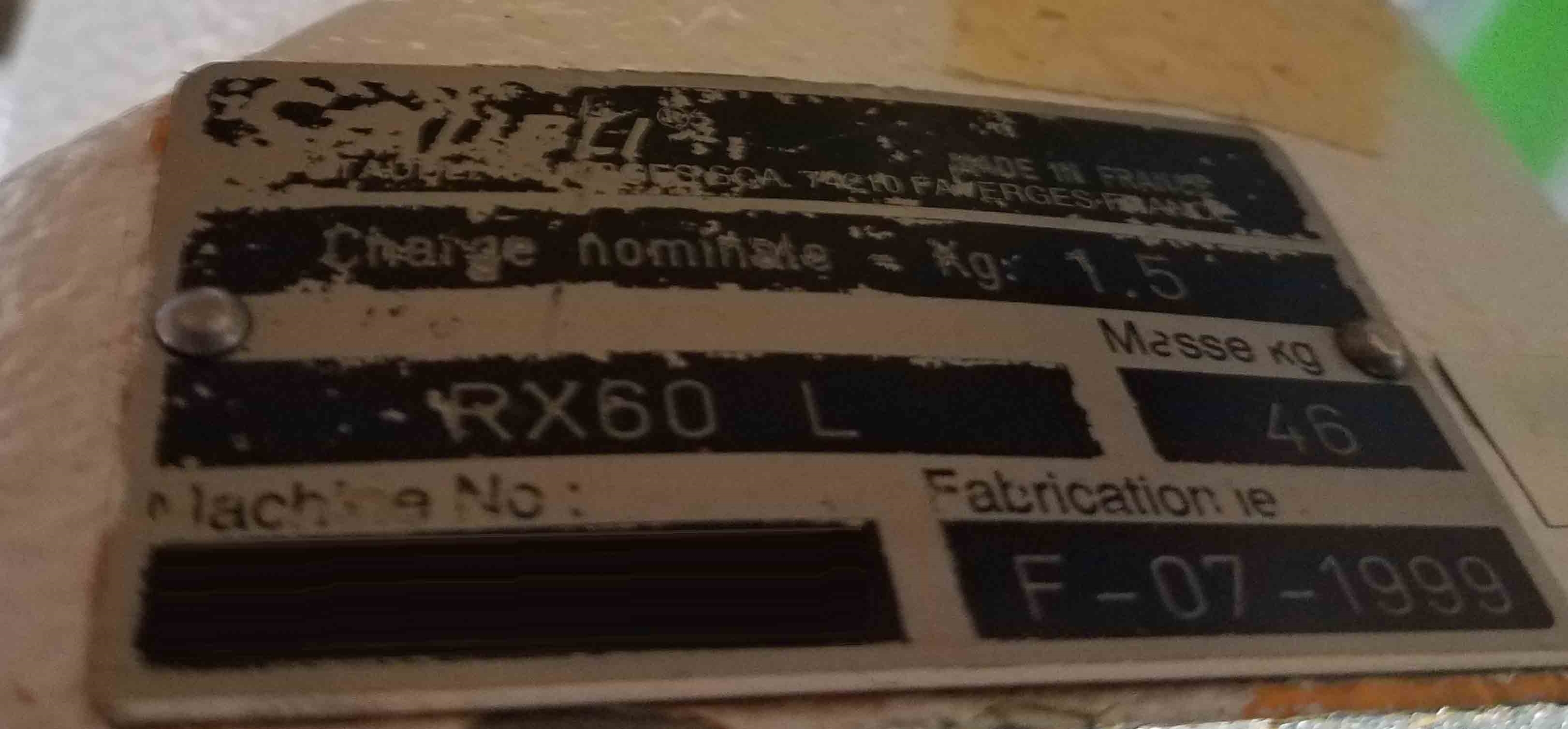

Used STAUBLI RX60 #9205960 for sale

URL successfully copied!

Tap to zoom

STAUBLI RX60 is an automated wafer handler designed to efficiently sort, transport and align wafers for laboratory and production processes. The device is composed of multiple units or modules, each designed to perform a specific function. The modules include an intake unit, sorting unit, wafer transport, and light pressure motorized alignment. Each module can be combined and combined in a custom way, making RX60 a highly configurable robotic solution for a wide range of applications. To begin, the intake module of STAUBLI RX60 is designed to quickly and accurately process incoming wafers from a variety of sources including inspection systems, grid bays, test plates, and standard carriers. This module is capable of quickly moving wafers and accurately controlling their movement. Additionally, the intake module is designed with an adjustable wafer gap that allows it to easily accommodate various wafer sizes. The sorting unit of RX60 is designed to efficiently categorize wafers into multiple bins and stacks for easy retrieval. It is capable of sorting wafers according to various criteria such as wafer ID or die size. The sorting unit also has an adjustable tilt angle that allows it to easily accommodate varying wafer shapes. The wafer transport of STAUBLI RX60 is designed to move between the input and output ends of the device in a repeatable and reliable manner. The wafer transport is powered by a brushless moto that offers a high degree of accuracy and reliability. The module also includes a feedback system that allows the device to fine tune its speed and positioning. Additionally, the wafer transport is equipped with advanced safety sensors that allow it to precisely monitor the status of the wafer during transport. The light pressure motorized alignment module of RX60 is designed to allow the device to accurately and quickly align incoming wafers into the required position. This is done by using precise pneumatic drive units powered by a brushless moto and a low-pressure membrane system that fine tunes the wafer alignment. The module is capable of quickly and accurately positioning wafers into any desired orientation. STAUBLI RX60 is an all-in- one automated wafer handler designed to efficiently sort, transport, and align wafers for laboratory and production processes. The device is composed of multiple modules, designed to perform distinct functions such as intake, sorting, transport, and light pressure motorized alignment. Each module can be configured and customized in a variety of ways, making RX60 an ideal robotic solution for a wide range of applications and wafer sizes.

There are no reviews yet