Used STAUBLI TX60 #293620477 for sale

URL successfully copied!

Tap to zoom

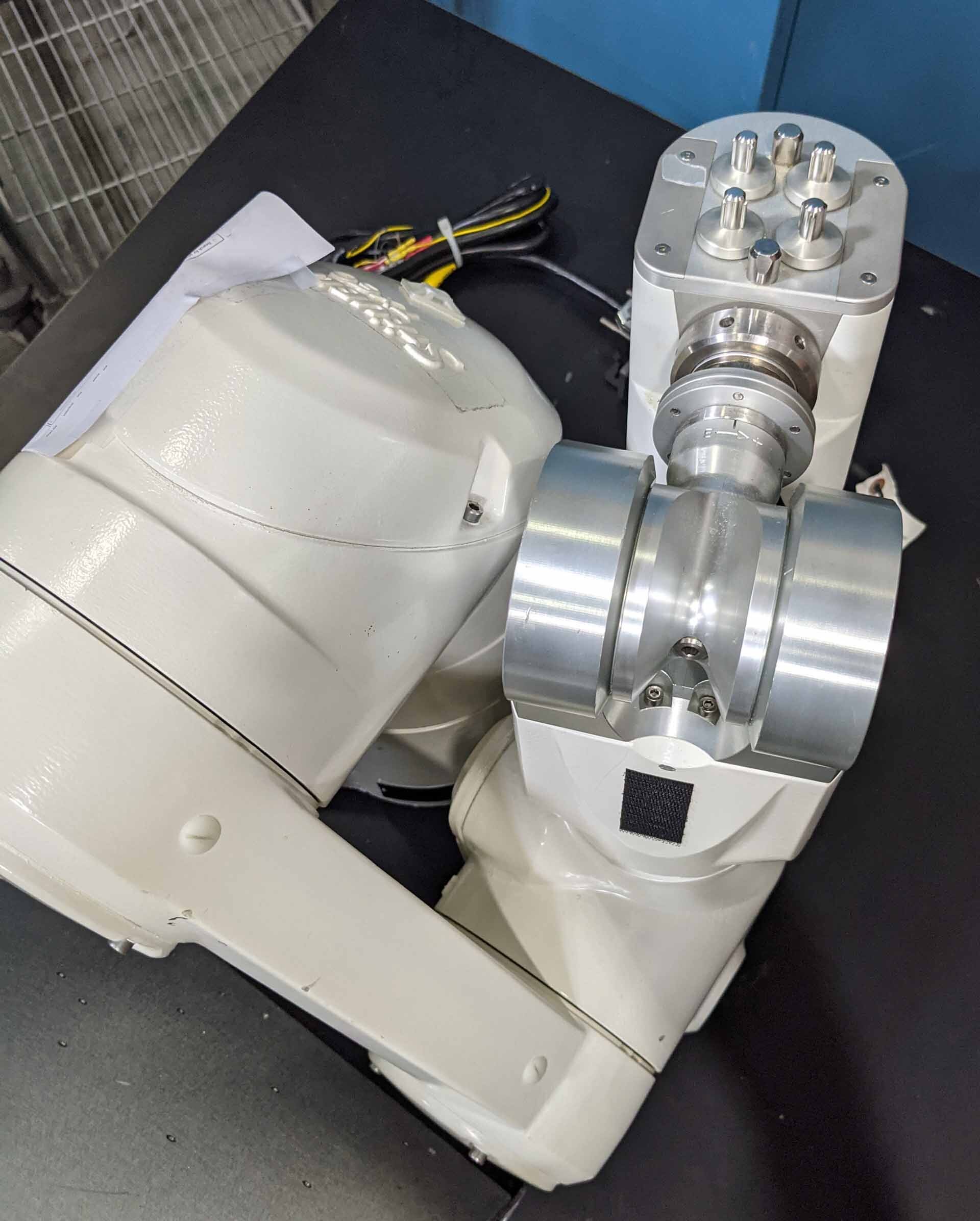

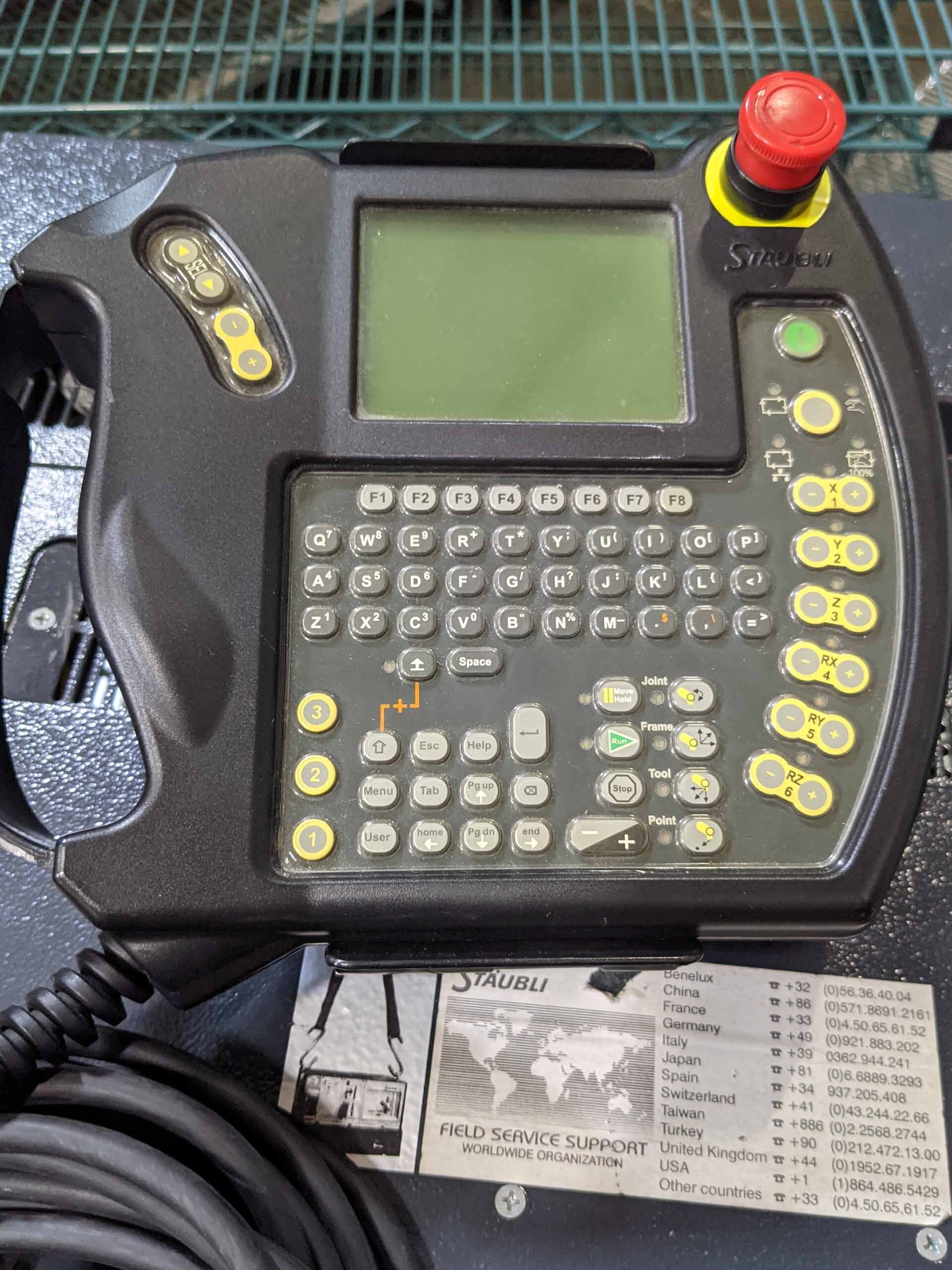

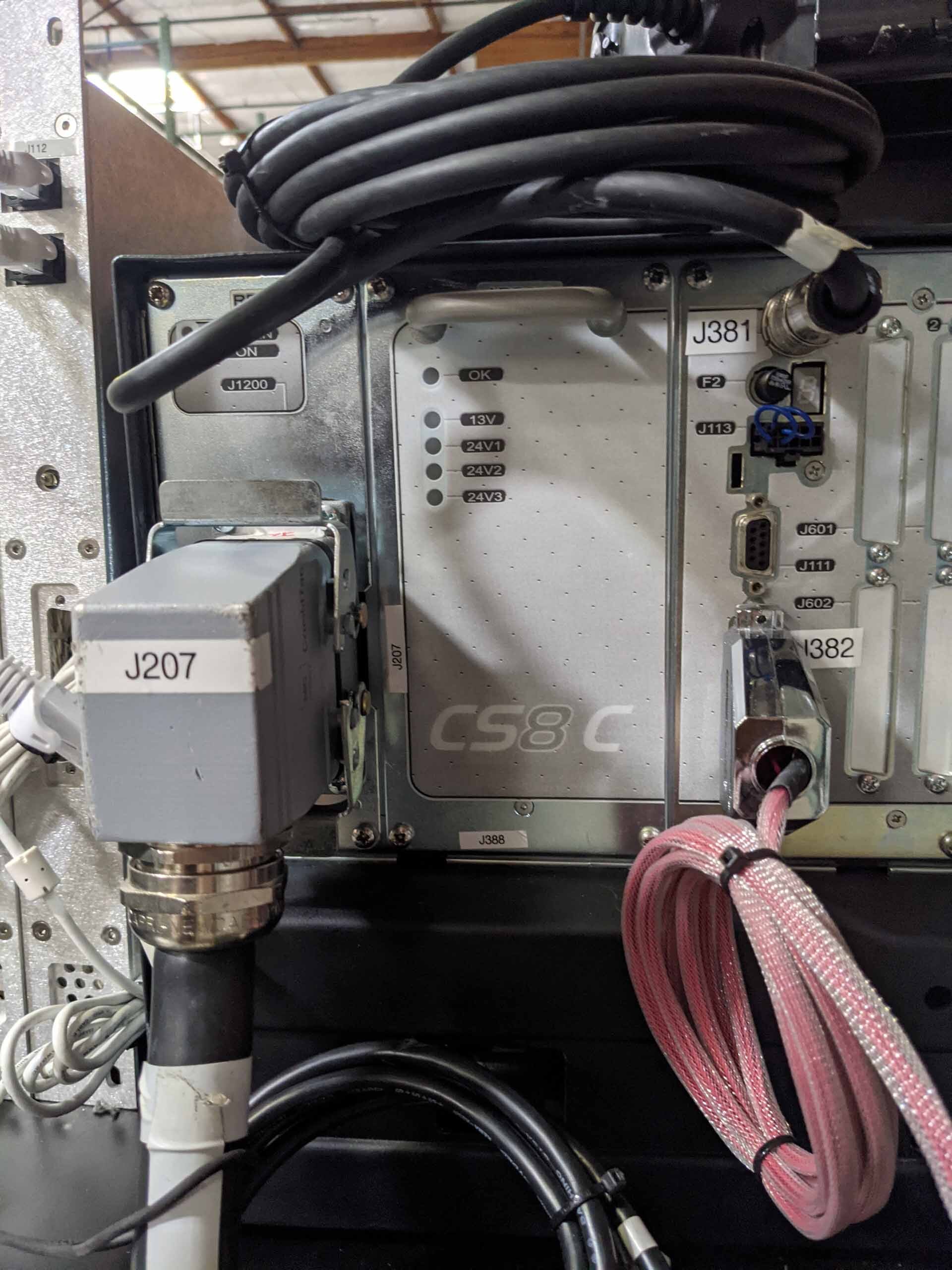

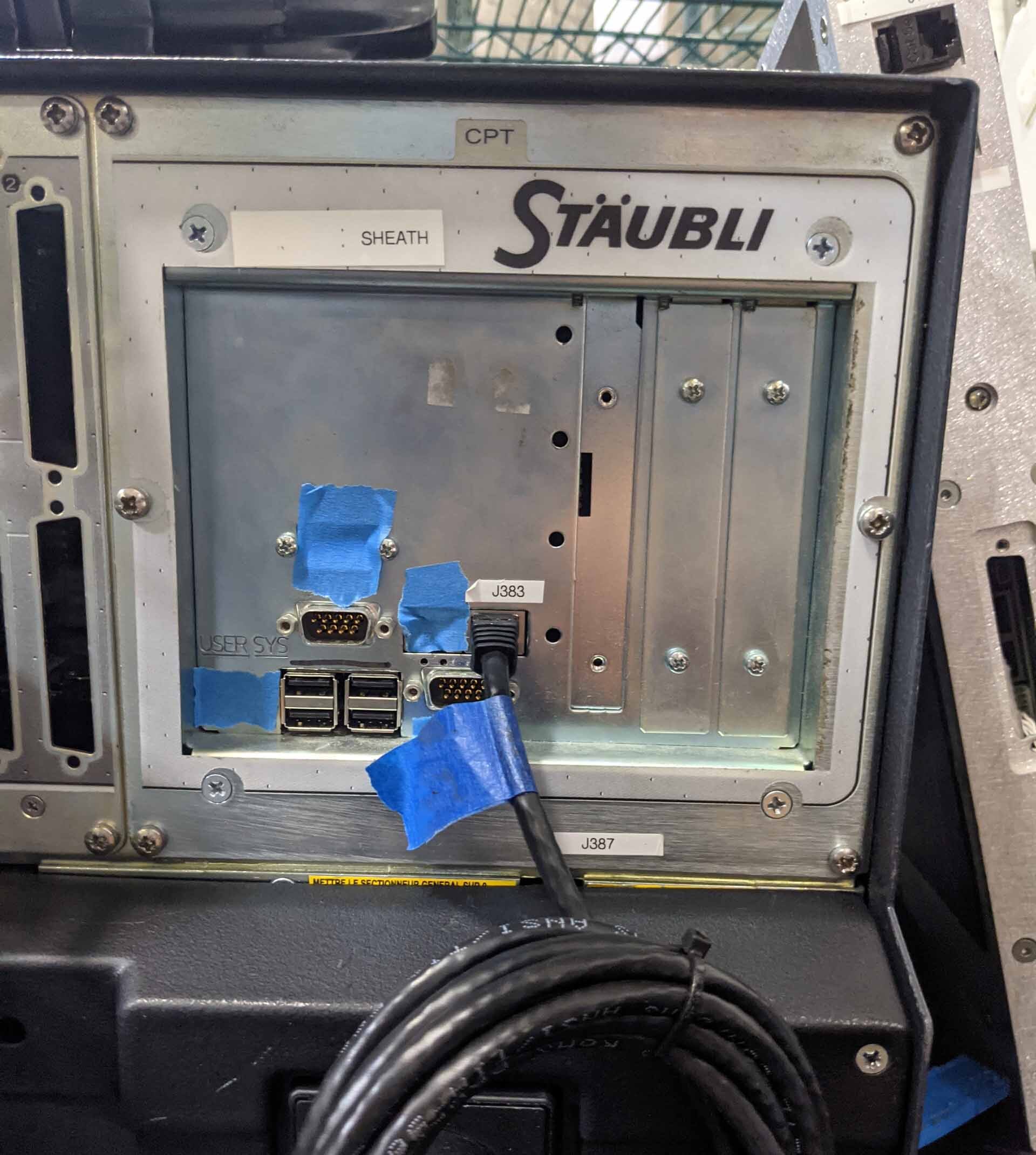

The Stäubli STAUBLI TX60 wafer handler is an automated robotic platform that specializes in transferring, loading, unloading, and managing sensitive semiconductor components such as wafers, dies, and bare dies. It can be used for semiconductor manufacturing and supporting applications like semiconductor packaging processes. TX60 wafer handler's core feature is its compact, low-profile design that allows efficient loading and unloading of wafers. An internal robot that features a precision independent toolhead helps automate the loading and unloading of wafers with up to 6 tools. The wafer handler's quick transfer speed results in fewer delays regarding the loading and unloading of wafer products. STAUBLI TX60 also has flexible design capabilities that accommodate a variety of wafer and die shapes regardless of the manufacturing process. The robot's flexibility helps reduce time-to-market by decreasing process steps, improving efficiency, and cutting down development costs. Moreover, StäubliTX60 wafer handler is designed to reduce maintenance time, making it easier to use and maintain even for the most demanding applications and production environments. The wafer handler has a maintenance-free, hybrid air bearing and agitator system, which helps reduce maintenance time and improve operation. The robotic platform also has an intuitive, visual feedback system that helps identify potential problems quickly. STAUBLI TX60 is also PC compatible, meaning it can be operated with a PC, operators can communicate with TX60 using their ISO 9001 compliant software. This feature helps to ensure the data collected through the system is available for analysis, post-process audit, and other review processes. Overall, STAUBLI TX60 wafer handler is an all-in-one, automated solution suitable for a variety of wafer-handling scenarios. It is designed to be flexible, efficient, and intuitive and provides a reliable, secure platform for handling critical semiconductor components. It also ensures accurate, fast processing of delicate items, reducing delays, and time to market.

There are no reviews yet