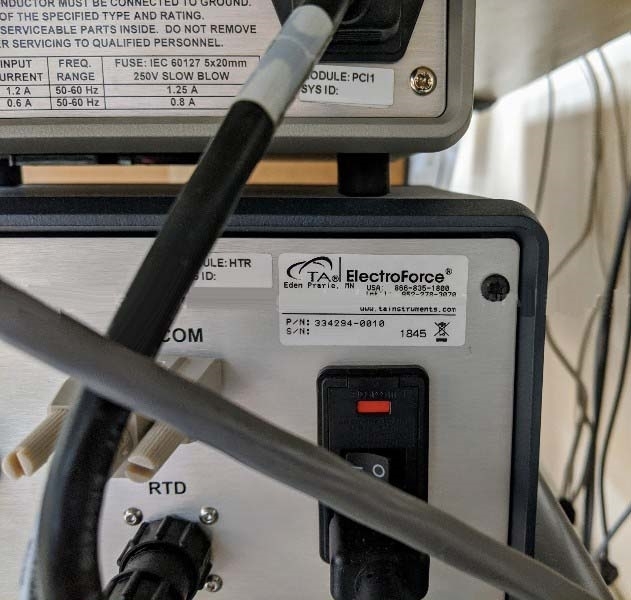

Used TA INSTRUMENTS ElectroForce 5500 #9286932 for sale

URL successfully copied!

Tap to zoom

ID: 9286932

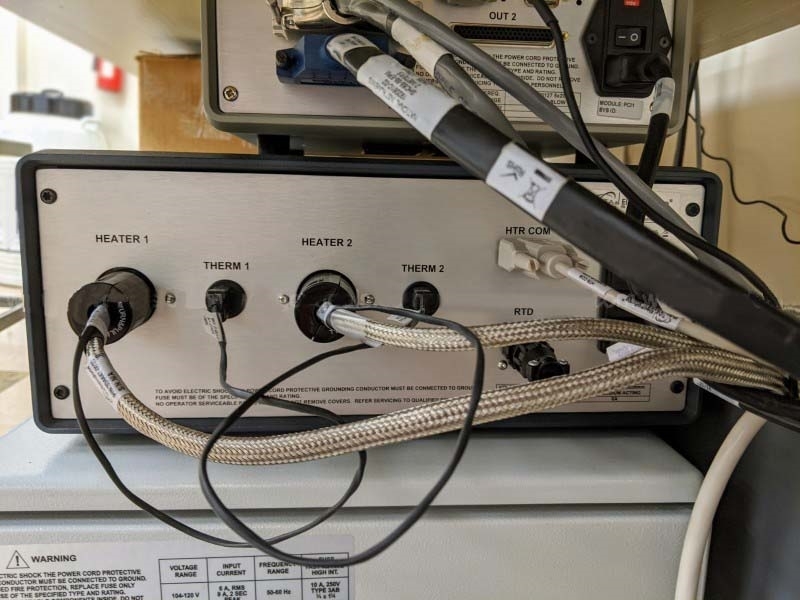

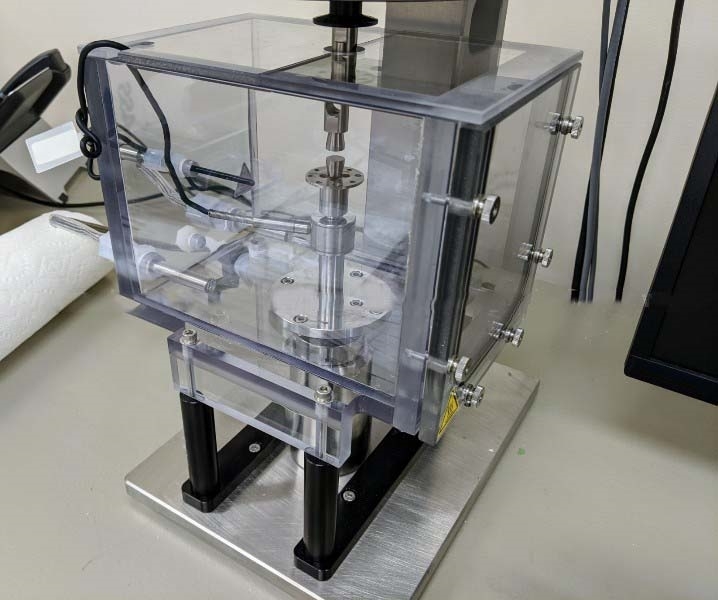

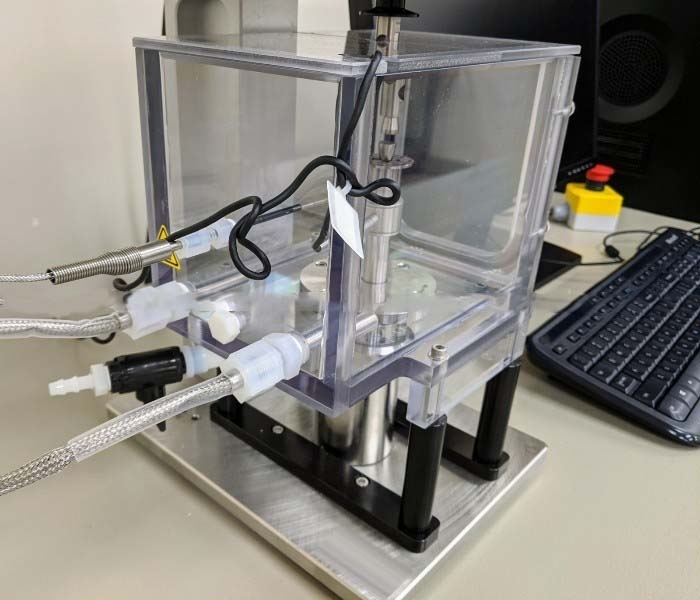

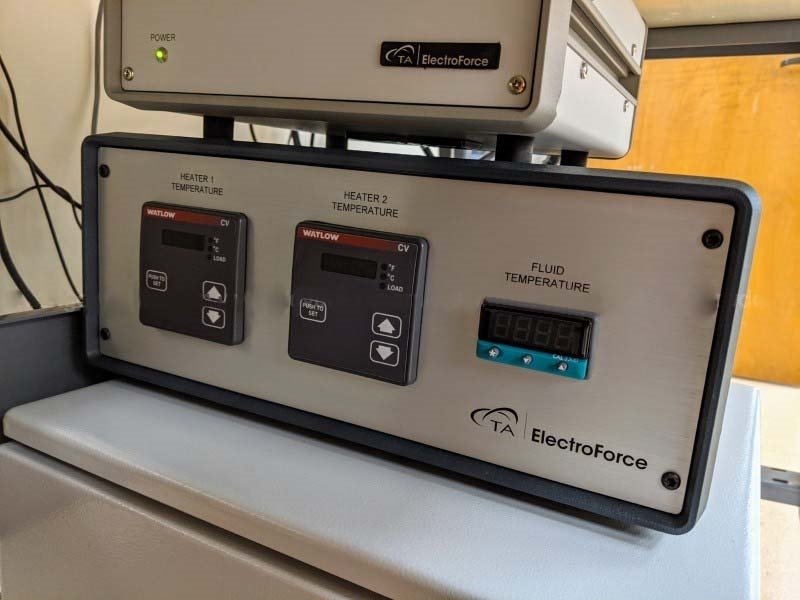

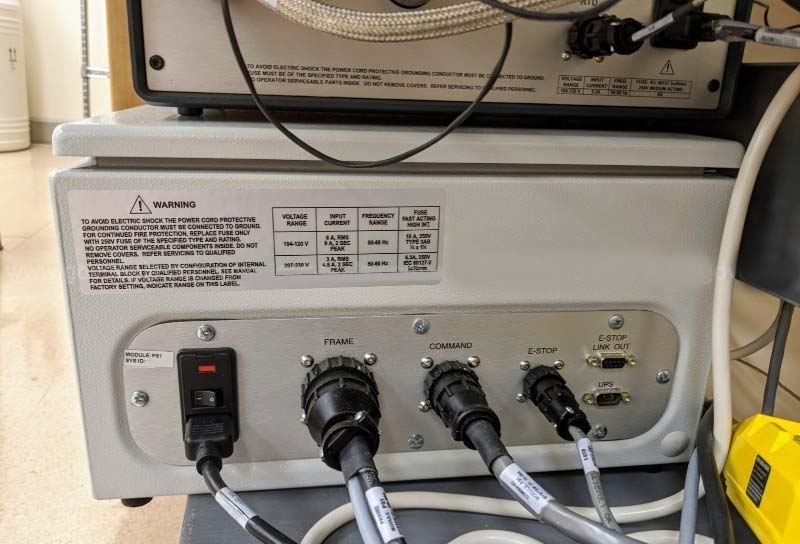

Load frame system

Mini load sensor kit

Compression platens

Workstation

Monitor

Operating manuals.

TA INSTRUMENTS ElectroForce 5500 is a smart, adaptable wafer handler that can cover a wide range of wafer sizes from 200 mm to 4.5". This automated handler ensures that there is minimal manual handling of wafers within the lab or the production fab. It is designed to transport wafers smoothly and accurately in a secure environment, without risking the contamination or damage of sensitive wafers, substrates, or die. The wafer handler provides precise control of jetting, wafer handling, and the delicate environment within the enclosure, ensuring that no particles enter the system. This ensures that the device remains safe and secure for long-term use. The wafer handler comes with a modular architecture, which allows for the addition of various components and tools that are required for the wafer inspection process. This includes vision systems, ion chucks, substrate carriers, thermal plates, and other tools. Additionally, the device has dual-zone access and internal stepper motors that help ensure accuracy in every step of the testing process. This also helps optimize the throughput and avoids potential hindrances to production due to human errors resulting from manual handling. Moreover, ElectroForce 5500 is a powerful and energy-efficient device, which helps conserve energy and reduce costs while maintaining precision in its operation. The device is carried out via a user-friendly graphical interface, with simple controls and operations, resulting in the rapid turnaround of jobs and improved accuracy. Furthermore, the device is capable of storing multiple configurations, making it easy to recall the desired process when needed. This helps to reduce the risk of errors and allows multiple jobs to be done efficiently. All in all, TA INSTRUMENTS ElectroForce 5500 is an efficient and reliable wafer handler that can help reduce the amount of manual handling of wafers, resulting in an overall improved cleaning quality and chip setup times. It can help to improve the accuracy of testing processes within the lab or production fab, with a user-friendly interface and a wide range of features that ensure precision and accuracy in the wafer handling process.

There are no reviews yet